Trenching resistance welding type IGBT module base plate

A bottom plate and solder resist technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of solder layer thinning, inability to realize molten solder diversion, accumulation, etc., to prevent insulation failure, improve insulation capacity and power Circulation ability, the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

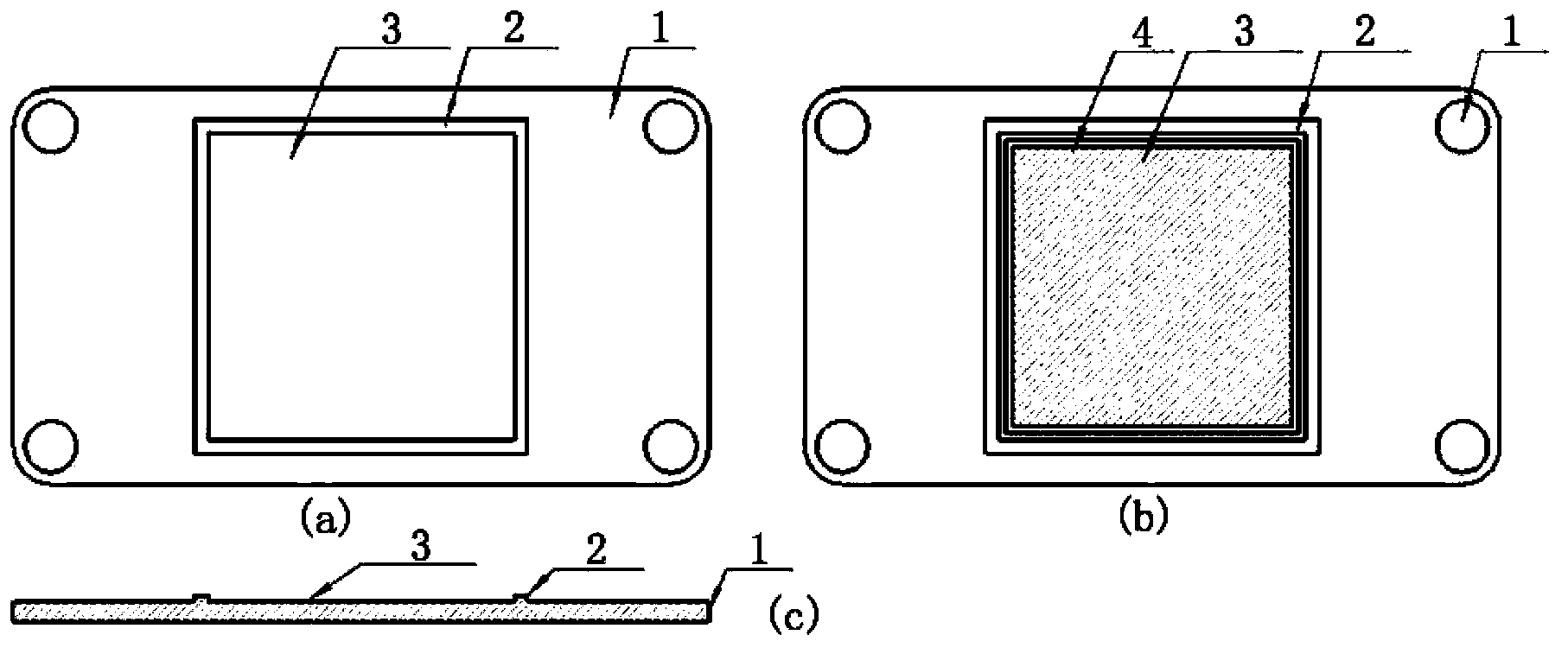

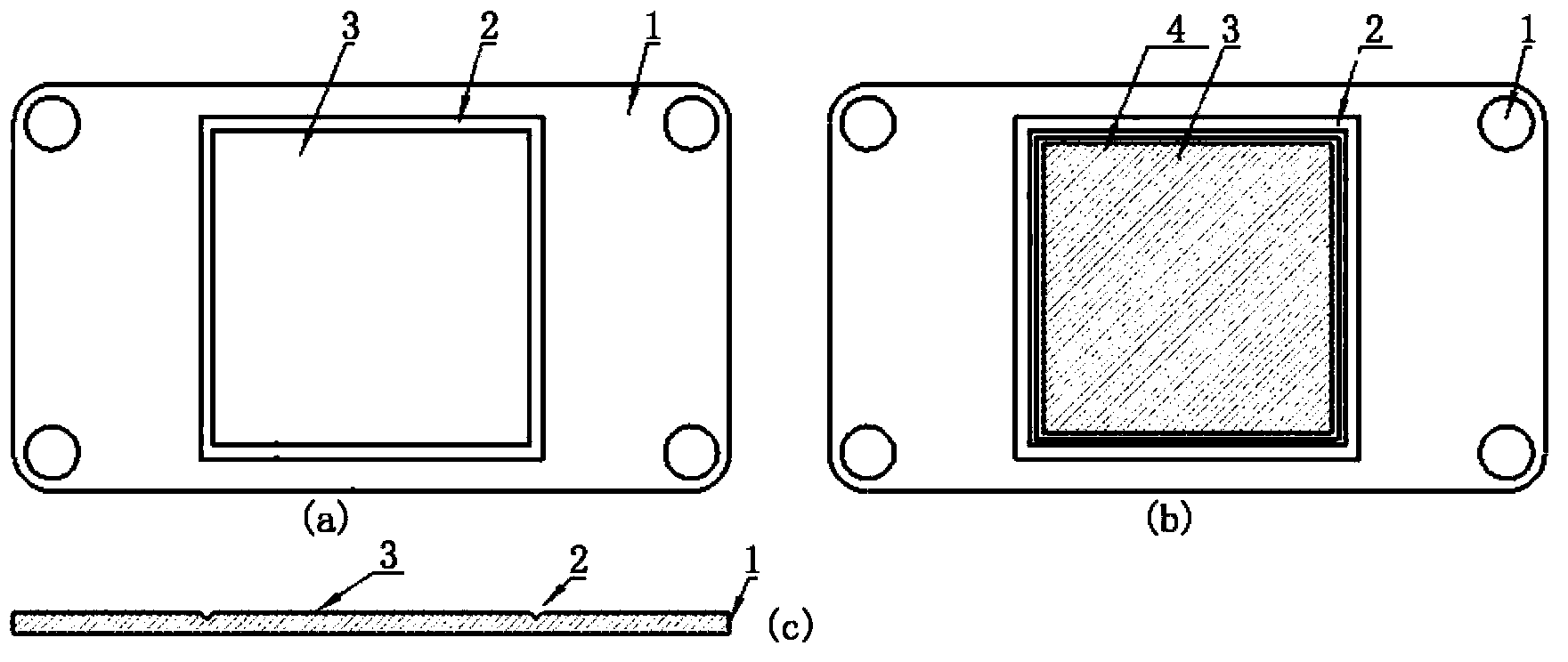

[0023] The invention discloses a slotted and solder-resistant IGBT module bottom plate. Grooves are arranged on the edge of the welding area of the slotted and solder-resistant IGBT module bottom plate. form a closed circle.

[0024] Preferably, in the above-mentioned slotted solder resist type IGBT module bottom plate, the shape of the groove is U-shaped or V-shaped.

[0025] Further, in the above-mentioned slotted solder resist type IGBT module bottom plate, the shape of the groove is V-shaped.

[0026] Preferably, in the above-mentioned slotted solder resist type IGBT module bottom plate, the depth of the groove is less than or equal to the designed solder thickness between the substrate and the module bottom plate.

[0027] Preferably, in the above-mentioned slotted solder resist type IGBT module bottom plate, the width of the upper end surface of the groove is less than or equal to 3 mm.

[0028] The invention also discloses an IGBT module, which includes a bottom pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com