Method for forming isolation grooves among pixels of CMOS (complementary metal oxide semiconductor) image sensor

A technology for image sensors and isolation trenches, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of large leakage current of semiconductor devices, affecting the photoelectric characteristics of CMOS image sensors, and destroying substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

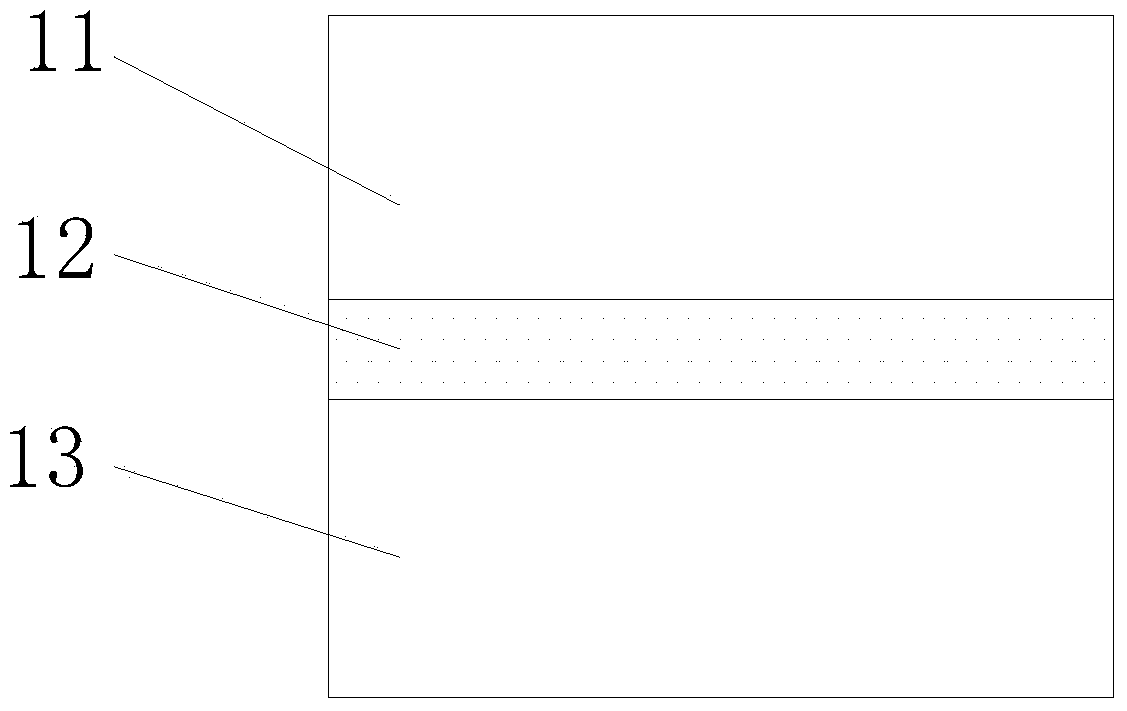

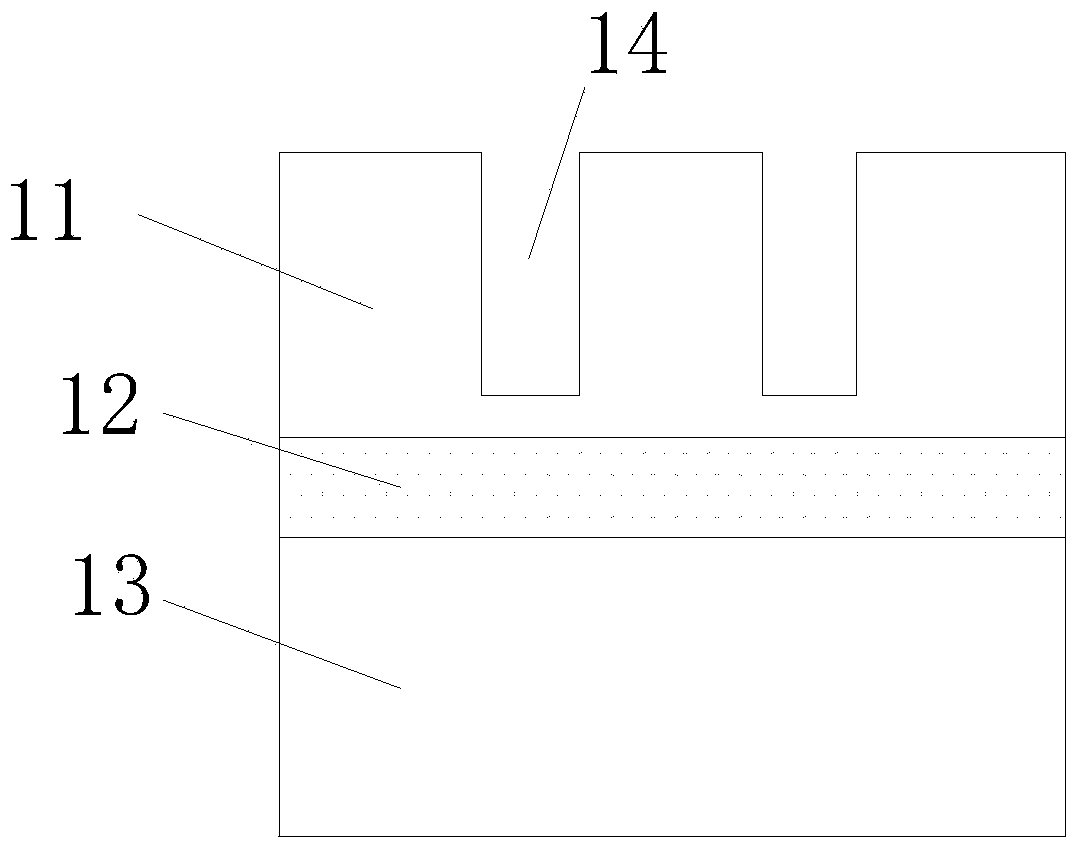

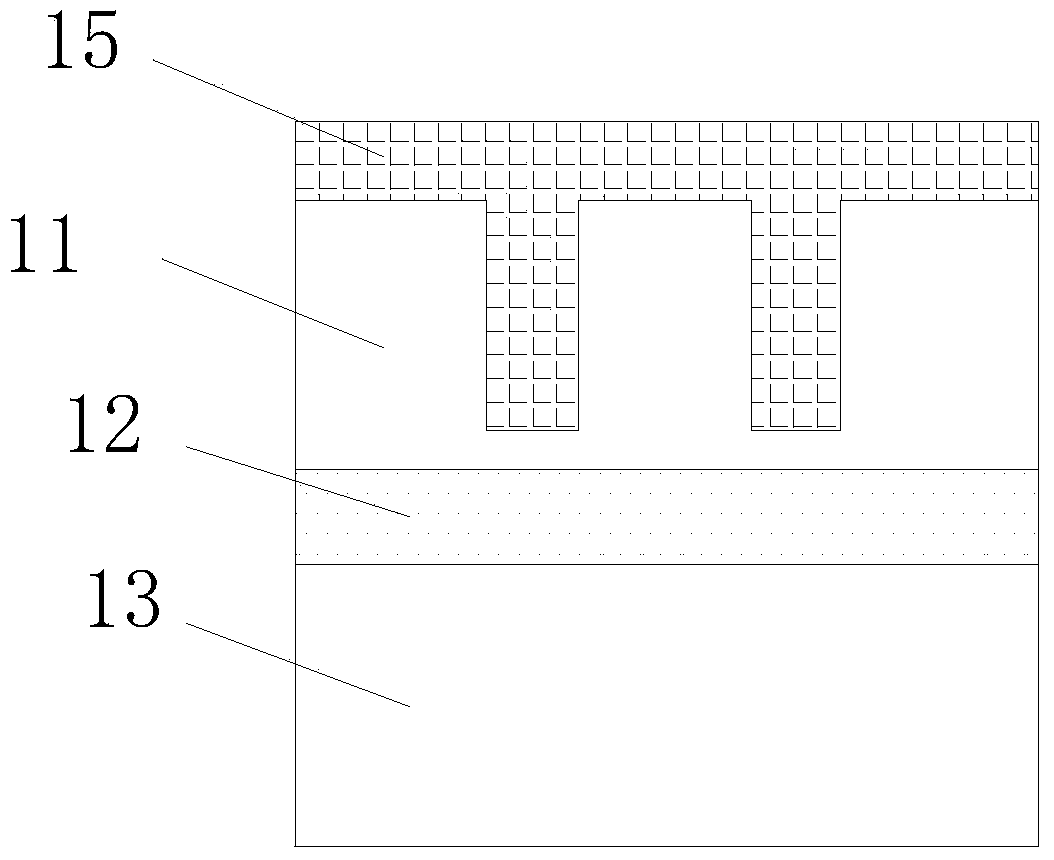

[0033] The core idea of the present invention is: cover a barrier layer on the upper surface of a bonded wafer, and use lithography process and first wet etching process to etch a number of pattern windows on the barrier layer, and use the barrier layer A second wet etching process is performed on the wafer for the mask to replace the traditional dry etching process, several isolation trenches are formed in the wafer and subsequent oxide filling is performed.

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0035] Step S1, preparing a bonded wafer, the bonded wafer includes a first wafer and a second wafer, the first wafer is located above the second wafer, and the front surfaces of the two wafers are bonded to each other, specifically , the first wafer includes a first substrate 21 and a first BEOL dielectric layer 22, and the second wafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com