Production process of instant vinegar-processed scad slices

A production process, the technology of horse mackerel, is applied in the field of production technology of instant vinegar pickled horse mackerel small slices, which can solve the problem of not being able to meet the nutritional requirements of consumers, unable to meet the requirements of instant food and a certain shelf life, and the lack of horse mackerel food. Report and other issues, to achieve the effect of beautiful products, enhanced value and profit margins, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

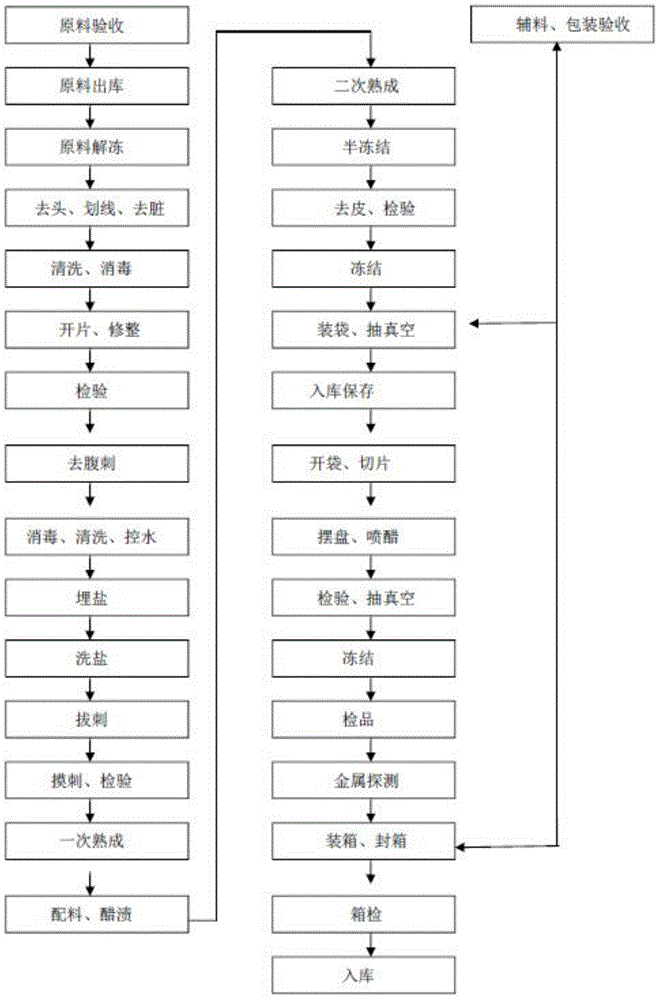

[0052] From figure 1 A kind of production technology of shown instant pickled horse mackerel small slices can be known, and it comprises the following steps:

[0053] (1) Handling of horse mackerel raw materials:

[0054] (1) Acceptance of raw materials: the surface of the fish body is shiny, the freezing hardness is good, the surface of the raw material body has no yellowing, no air-drying, no corruption, the smell is normal fish smell, no peculiar smell, the packaging is intact and there is no stain, the center temperature of the fish body is - Below 18°C;

[0055] (2) Raw material out of the warehouse: take the product out of the warehouse, and pay attention to handling it with care to avoid collisions causing defects;

[0056] (3) Raw material thawing: put the raw material on the thawing rack to thaw naturally, and thaw to 20%;

[0057] (4) Head removal, marking, and viscera removal: Put the thawed fish fillets on a white board, cut off the fish head obliquely along the...

Embodiment 2

[0086] The difference from Example 1 is that in the disinfection and water control of the first step and the 9th small step, the water was controlled for 3 minutes, and when the salt was buried in the 10th small step, the salt content was 4.8%. , other steps are with embodiment 1.

Embodiment 3

[0088] The difference from Example 1 is that in the disinfection and water control of the first step and the 9th small step, the water was controlled for 4 minutes, and when the salt was buried in the 10th small step, the salt content was 5.0%. , other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com