3D (3-dimnesional) printing manufacturing method for PDC (primary domain controller) drill bit body

A manufacturing method and 3D printing technology, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problems of cumbersome production, high cost, long cycle, etc., to improve overall performance, reduce production cost, and make up for machining and casting. The effect of defects in craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

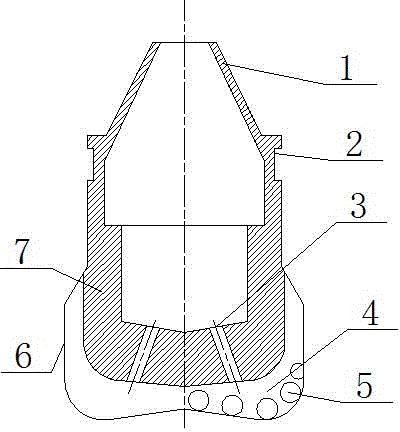

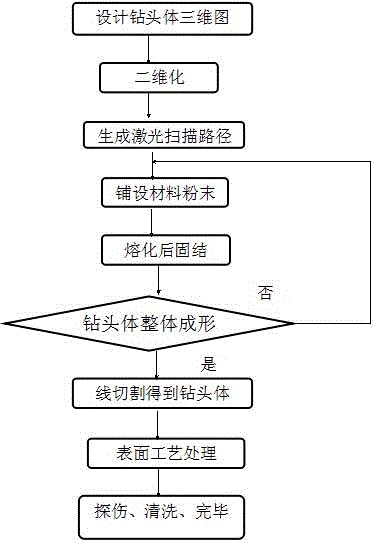

[0021] The structure diagram of the PDC bit body in this embodiment, such as figure 1 As shown, the specific operation steps are as follows figure 2 Shown. According to the specific requirements of the design, use 3D drawing software such as AutoCAD, Unigraphics NX, Pro-E or CATIA to design the overall 3D model of the PDC bit body, including the thread 1, shackle groove 2, nozzle hole 3, scraper of the PDC bit body Wing 4, PDC cutting teeth 5, gauge and crown 6, bit body 7, etc., use the software RP-Tools to perform two-dimensional processing on the 3D model of the PDC bit body:

[0022] That is, the structure is cut into a series of two-dimensional graphic layers with a layer thickness of 0.01 μm in the Z-axis direction, and then the series of two-dimensional graphics are imported into the software EOS PSW3.5, which automatically calculates the two-dimensional layer of each layer according to the image The laser scanning path and use parameters of the graphics, and then spread...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com