Polyamide hot melt adhesive used in electronic packaging field

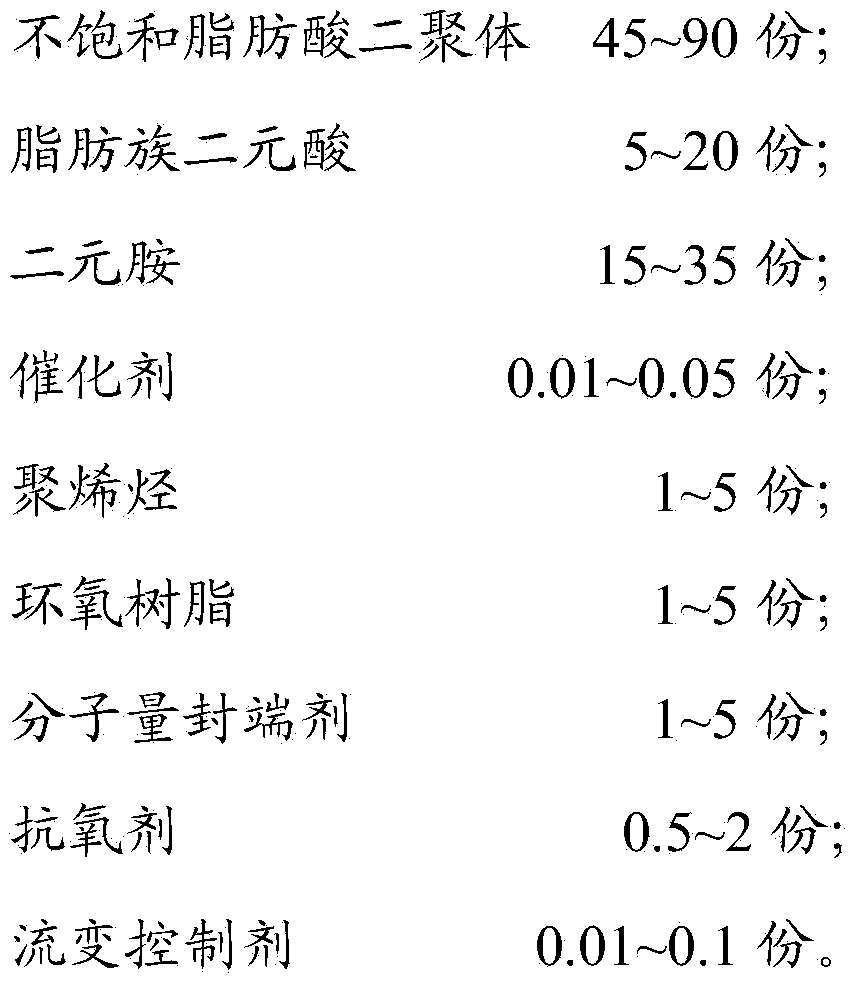

A polyamide hot-melt adhesive and electronic packaging technology, which is applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problem that the low-pressure injection molding process cannot be used, the viscosity of polyamide hot-melt adhesive is high, and it is inconvenient to apply to packaging Aspects and other issues, to achieve the effect of uniform sizing process, low injection pressure requirements, and moderate hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

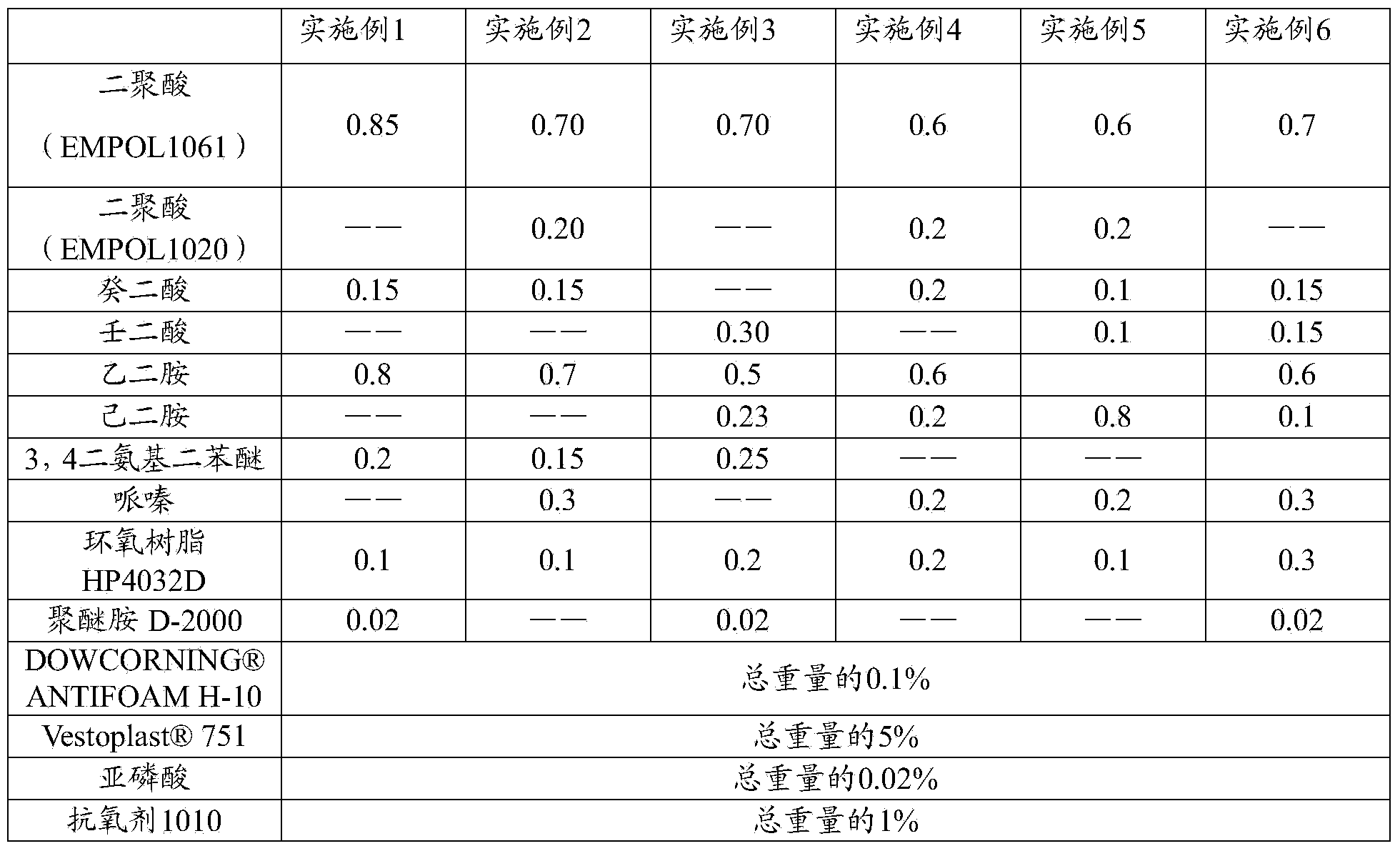

[0019] A polyamide hot melt adhesive used in the field of electronic packaging, prepared with the following components in parts by weight: 0.85mol Empol 1061, 0.15mol sebacic acid, 0.2mol 3,4 diaminodiphenyl ether, 0.1mol epoxy Resin, 1.5g antioxidant 1010, 0.80mol ethylenediamine and 0.02mol polyetheramine D-2000.

[0020] Preparation:

[0021] 0.85mol dimer acid Empol 1061 (purchased from BASF, Germany, 95% dimer acid content), 0.15mol sebacic acid, 0.2mol 3,4 diaminodiphenyl ether, 0.1mol epoxy resin Epiclon HP-4032D ( (Purchased from Japan DIC company), polyolefin 751 (purchased from Degussa, Germany) and 1.5 g of antioxidant 1010 were put into a 1000 ml three-necked flask, and the temperature was slowly raised under nitrogen protection until the raw materials in the flask were completely dissolved, and the temperature was maintained at 130°C. 0.80mol ethylenediamine and 0.02mol polyetheramine D-2000 were dropped into the reaction flask at this temperature. Finish the drip w...

Embodiment 2~6

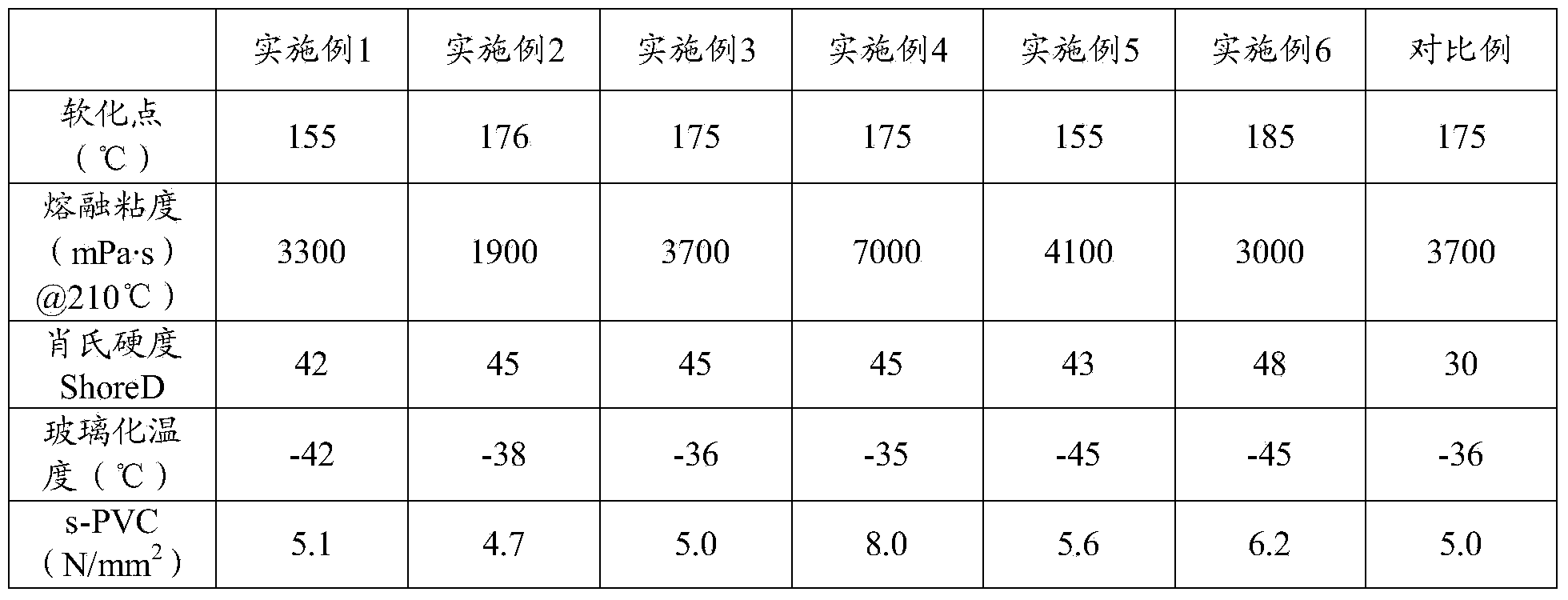

[0023] According to the formula in Table 1, referring to the process of Example 1, polyamide hot melt adhesive particles were prepared. The properties of the polyamide hot melt adhesives prepared in Examples 1 to 6 were tested according to the following methods, and the test results are shown in Table 2 and Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com