Thermal insulation joint mixture and laying method thereof

A technology of caulking agent and adhesive, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problem of unsatisfactory heat insulation effect at the gap, affecting the heat insulation effect of the heat insulation layer, and the gap filling is not dense enough, etc. problems, to achieve the effect of saving assembly time, excellent heat insulation performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

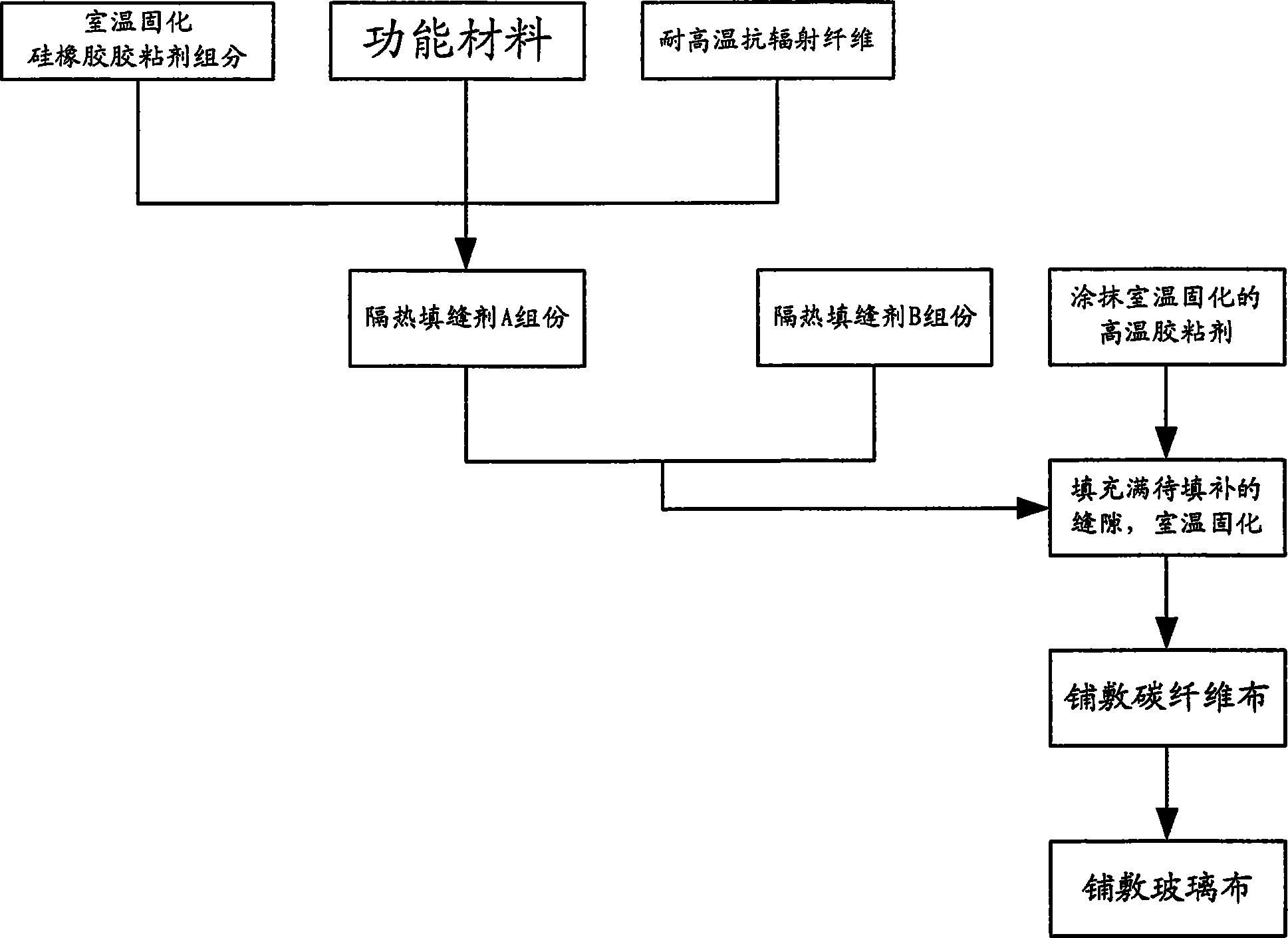

[0049] Preparation Process:

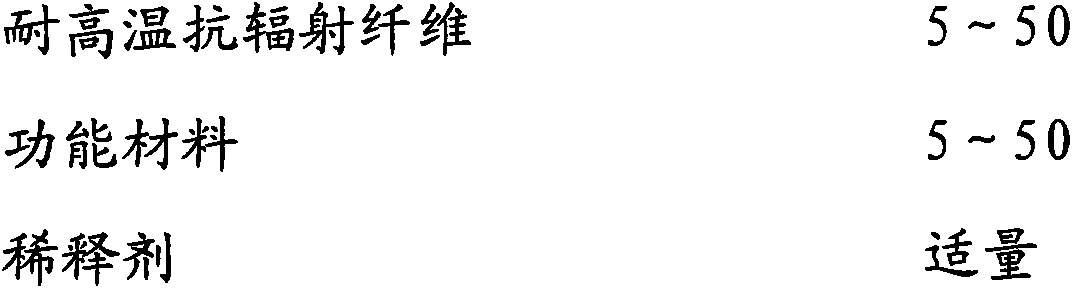

[0050] (1) Mix the KH-CL-RTV silicone rubber adhesive component with cyclohexane evenly, then add polyacrylonitrile pre-oxidized wire and aluminum oxide hollow microspheres into the silicone rubber adhesive that is stirred evenly, and stir evenly. The mass ratio is: KH-CL-RTV adhesive: cyclohexane: polyacrylonitrile pre-oxidized wire: aluminum oxide hollow microspheres = 100:50:50:50, after 24 hours of post-treatment at 50 ° C, the heat insulation sealant is obtained Component A: the diameter of the polyacrylonitrile pre-oxidized wire is 5 μm, and the length is 5 mm; the diameter of the aluminum oxide hollow microsphere is 50 μm.

[0051] (2) Mix the KH-CL-RTV silicone rubber adhesive curing agent component and cyclohexane evenly, and the mass ratio is 10:100 to obtain component B of the thermal insulation sealant.

[0052] (3) Clean up the gaps, and spread the gaps evenly with the evenly stirred two-component KH-CL-RTV silicone rubber adhesive. ...

Embodiment 2~15

[0061] Table 1 shows the raw materials used in the B component of the heat-insulating caulking agent and its preparation ratio in Examples 2-15, and Table 2 shows the raw materials used in preparing the A-component of the heat-insulating caulking agent in Examples 2-15 and its preparation ratio. Table 3 is Embodiments 2-15 laying process and performance test of heat-insulating sealant material, and other contents are the same as embodiment 1.

[0062] It can be seen from Table 3 that as the content of fibers and functional materials in component A of the thermal insulation sealant increases, its thermal insulation performance is better. Within the optimal proportion range, the back temperature after heating at 350°C for 700s is lower than 60 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com