Preheating device for chemical vapor deposition furnace

A chemical vapor deposition, preheating device technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of increasing the heat radiation capacity of the gas heating time, increasing the height of the preheating device, and the height of product charging. Reduce and other problems to achieve the effect of prolonging the residence time, increasing the charging height, and increasing the heat radiation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

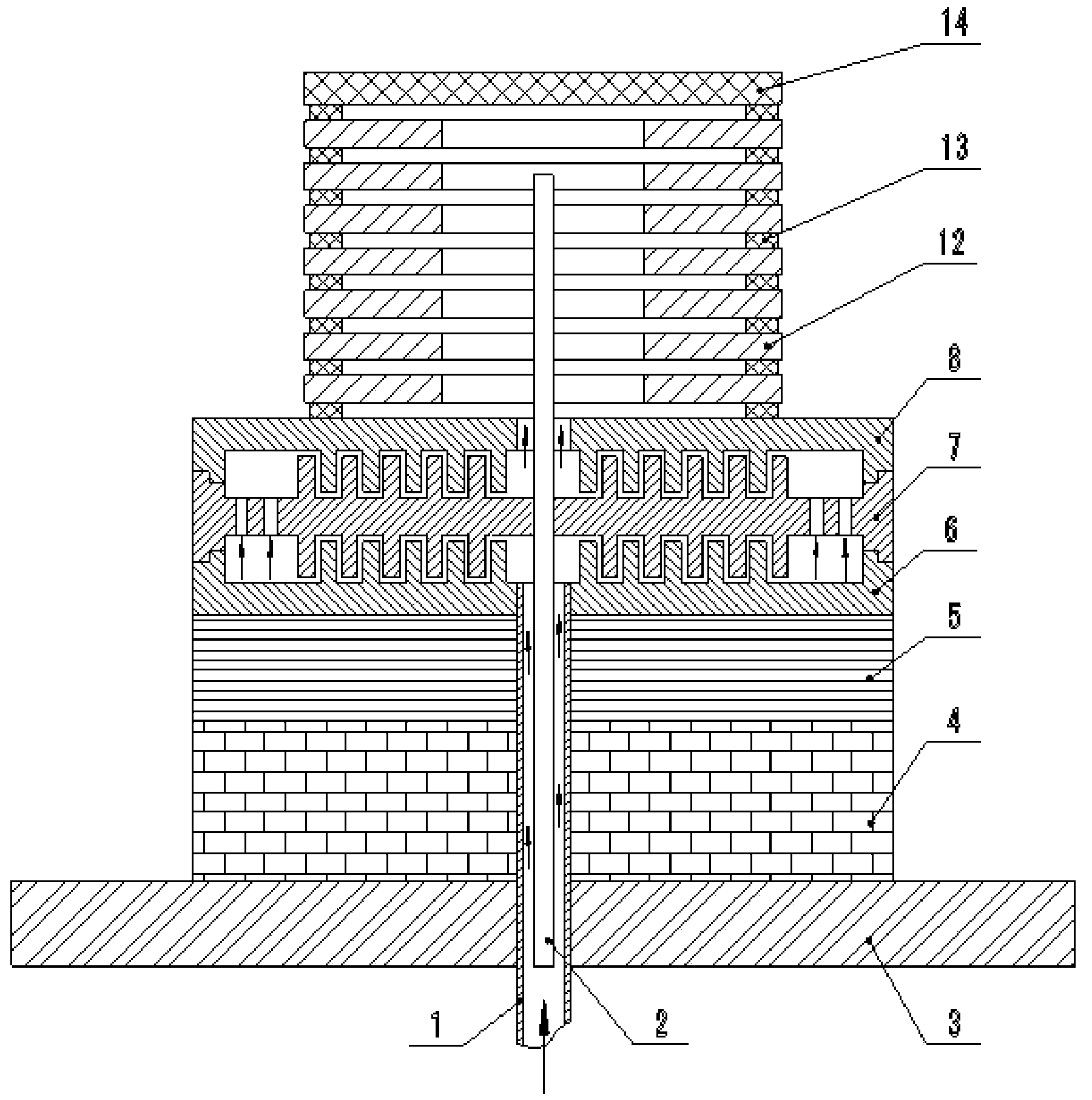

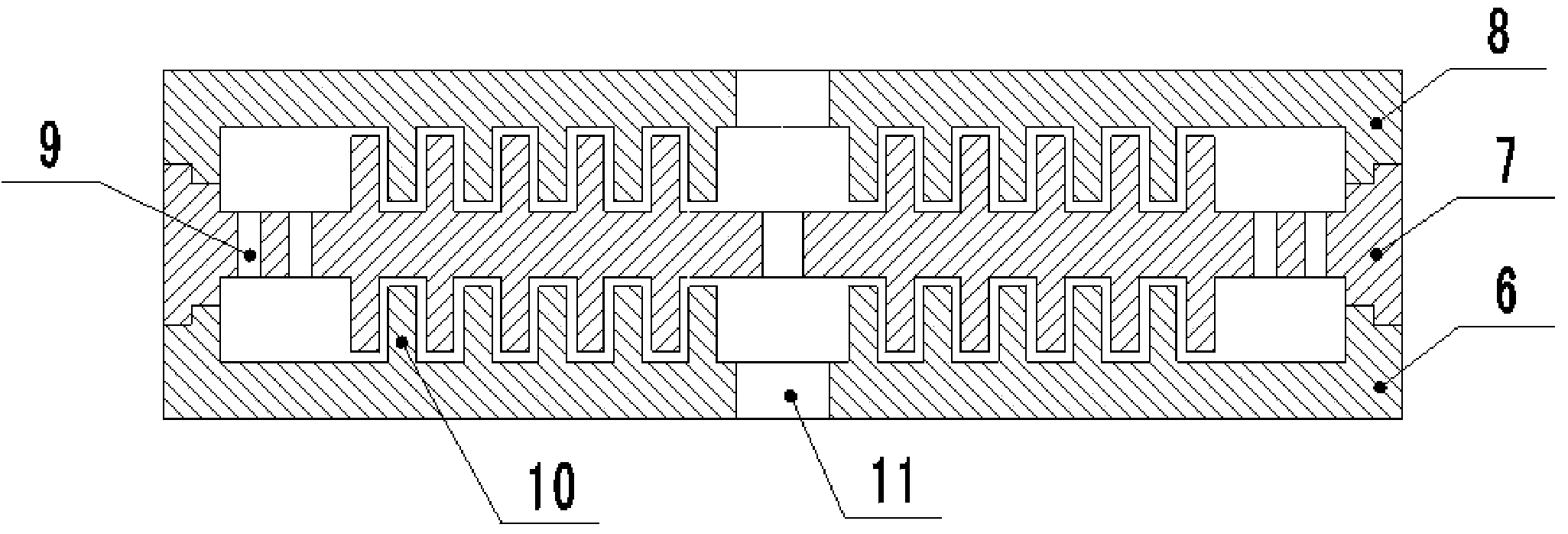

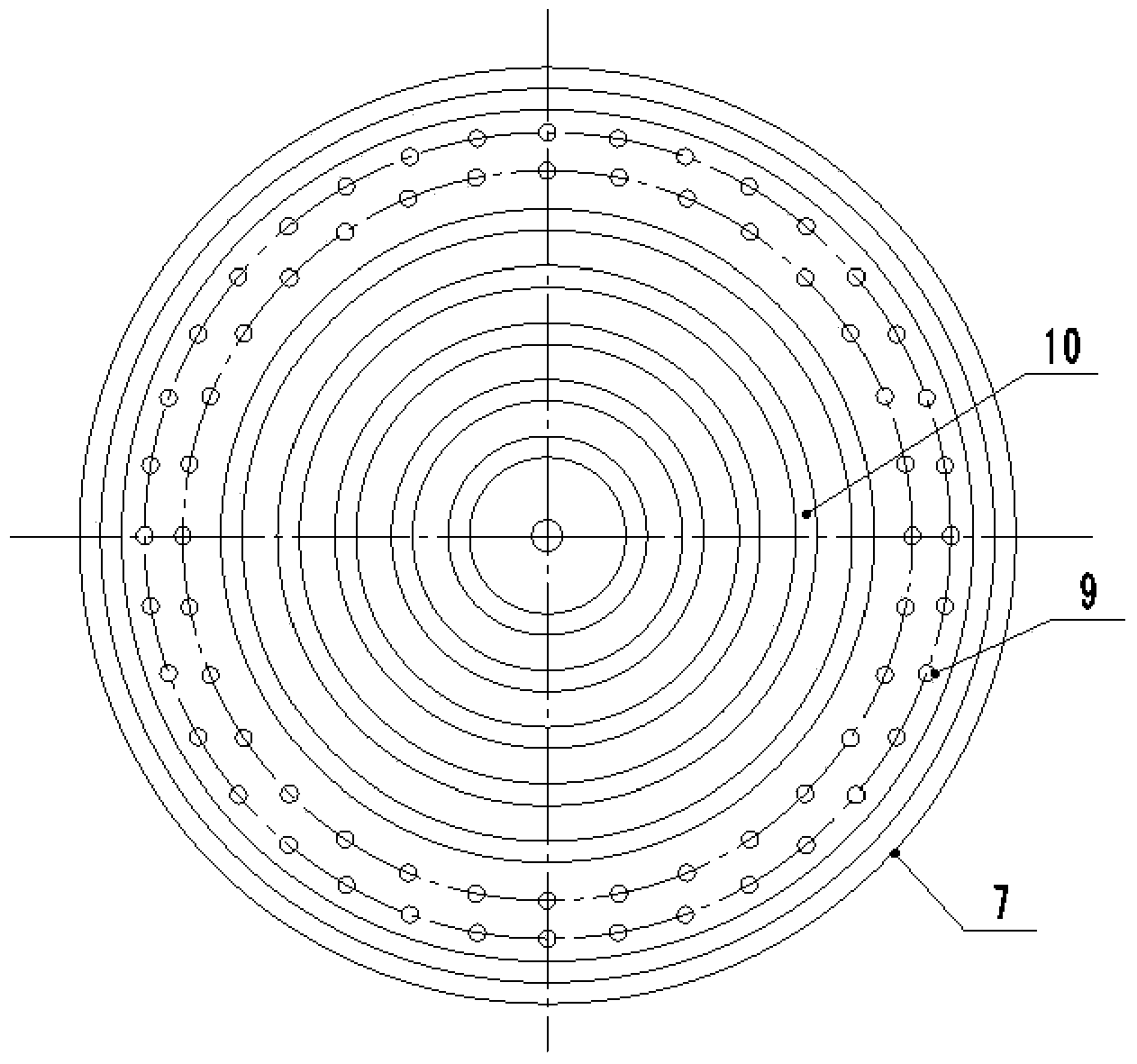

[0021] This embodiment is a chemical vapor deposition furnace preheating device, including a chemical vapor deposition furnace base and a preheating device, wherein the chemical vapor deposition furnace base is composed of a base bottom plate 3 , refractory bricks 4 , and insulation felt 5 . The preheating device is placed on the thermal insulation felt 5, the carbon fiber prefabricated body 12 is stacked on the surface of the preheating device, the carbon fiber prefabricated bodies 12 are separated by graphite gasket rings 13, and the graphite cover plate 14 is placed on the carbon fiber prefabricated body 12 material column the top of. The air intake pipe 1 is placed in the central hole of the base, and the end of the air intake pipe 1 communicates with the bottom end of the preheating device. The lower end of the thermocouple 2 is located in the intake pipe 1, and the upper end passes through the center of the preheating device and extends to the inside of the carbon fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com