Titanium alloy containing antibacterial coating as well as preparation method and application thereof

A technology of antibacterial coating and titanium alloy, which is applied in the direction of coating, metal material coating technology, prosthesis, etc., can solve the problems of complex processing equipment and high preparation cost, and achieve low preparation cost, promote application, and broad-spectrum antibacterial effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the titanium alloy containing antibacterial coating is as follows:

[0032] 1. Pretreatment

[0033] Polish the titanium sheet with 400, 1000 and 2000 mesh sandpaper to a bright surface, and then use tap water, ethanol, and acetone to ultrasonically clean it for 10 minutes each time; after cleaning, put it in an oven at 60°C for drying. After drying, put the titanium sheet into a sterile tube, wrap it with newspaper, put it in a high-pressure sterilizer for 20 minutes, and then take it out and put it in an oven to dry for later use;

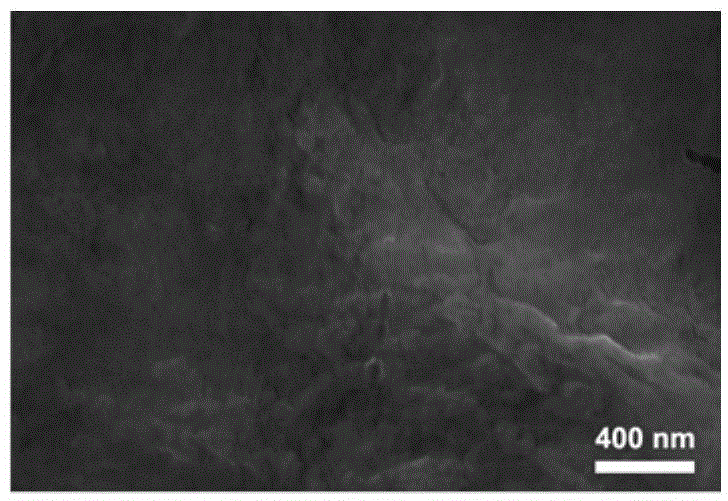

[0034] 2. Polydopamine deposition

[0035] Soak the titanium alloy treated in step (1) in 2 mg / mL dopamine hydrochloride solution for 12 hours to obtain a titanium alloy with a polydopamine film layer deposited on the surface;

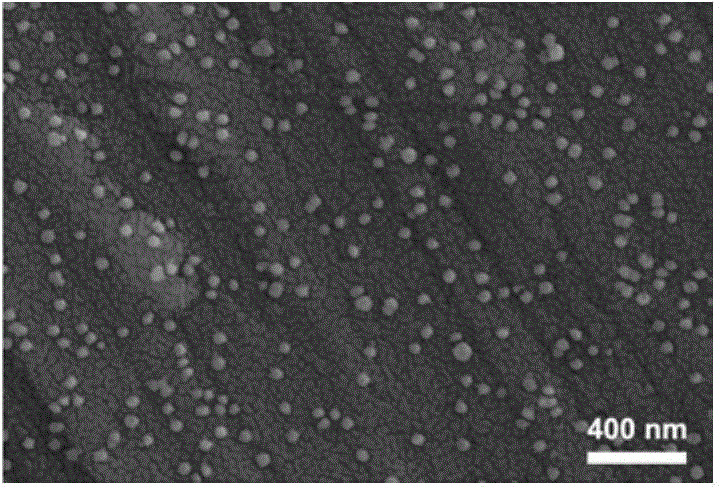

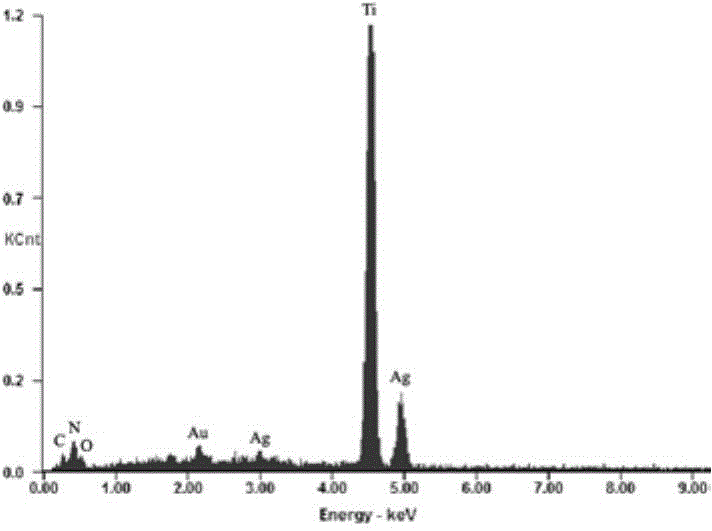

[0036] 3. Nano silver coating preparation

[0037] The titanium alloy treated in step (2) was immersed in a 12.5mmol / L silver nitrate solution for 12 hours to obtain a titanium alloy wi...

Embodiment 2

[0039] The preparation method of the titanium alloy containing antibacterial coating is as follows:

[0040] 1. Pretreatment

[0041] With embodiment 1;

[0042] 2. Polydopamine deposition

[0043] Soak the titanium alloy treated in step (1) in a 5 mg / mL dopamine hydrochloride solution for 24 hours to obtain a titanium alloy with a polydopamine film layer deposited on the surface;

[0044] 3. Nano silver coating preparation

[0045] Immerse the titanium alloy treated in step (2) in a 5 mmol / L silver nitrate solution for 24 hours to obtain a titanium alloy with nano-silver antibacterial coating deposited on the surface.

Embodiment 3

[0047] The preparation method of the titanium alloy containing antibacterial coating is as follows:

[0048] 1. Pretreatment

[0049] With embodiment 1;

[0050] 2. Polydopamine deposition

[0051] Soak the titanium alloy treated in step (1) in a 10 mg / mL dopamine hydrochloride solution for 36 hours to obtain a titanium alloy with a polydopamine film layer deposited on the surface;

[0052] 3. Nano silver coating preparation

[0053] The titanium alloy treated in step (2) was immersed in a 100mmol / L silver nitrate solution for 36 hours to obtain a titanium alloy with a nano-silver antibacterial coating deposited on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com