Rigid corrugated composite pipe and manufacturing method of rigid corrugated composite pipe

A technology of corrugated pipes and composite pipes, applied in the field of composite pipes, can solve problems such as poor safety, high replacement frequency, and small radial rigidity, achieve enhanced toughness and torque resistance, reduce corrosion probability, and improve radial strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

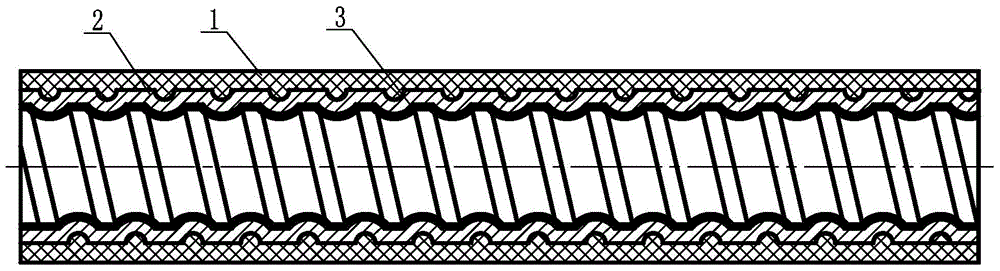

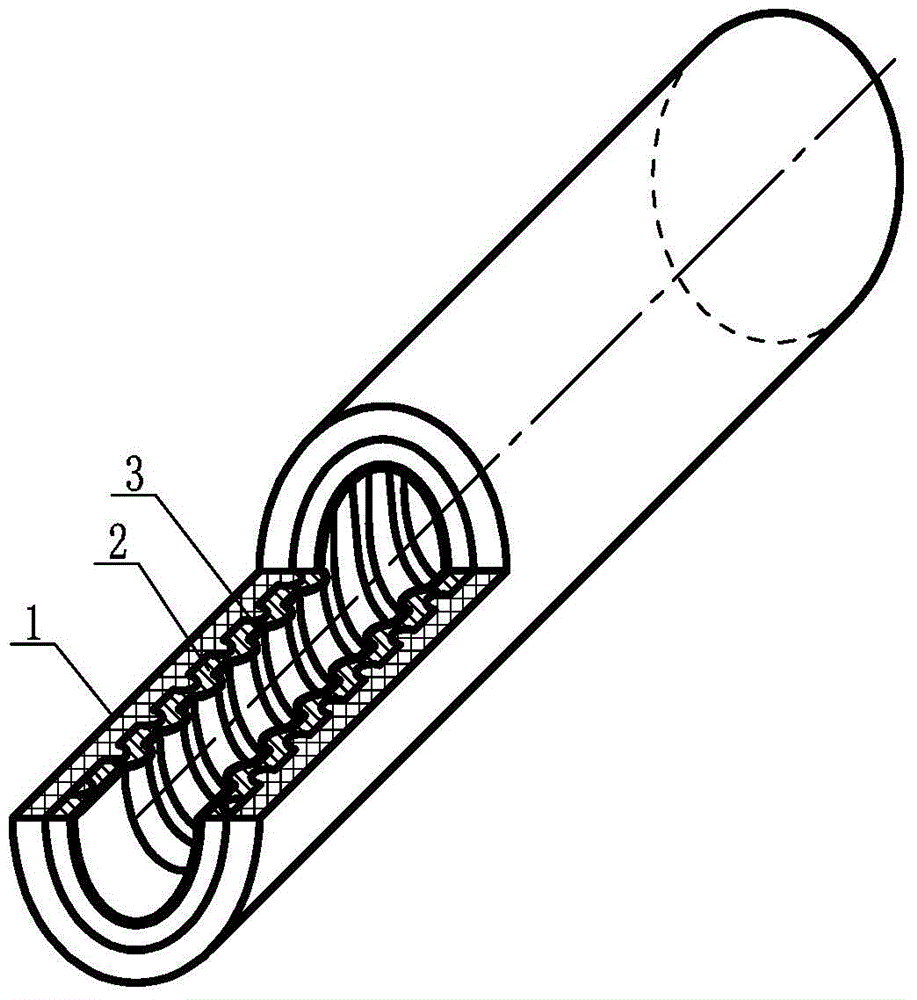

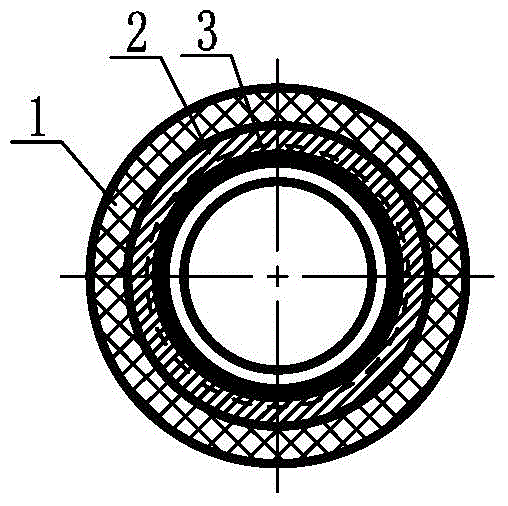

[0029] Such as figure 1 , figure 2 with image 3 As shown, the rigid corrugated composite pipe includes an outer modified plastic pipe 1 with a smooth outer surface, the outer modified plastic pipe 1 is covered with an inner metal rigid corrugated pipe 2, and the inner metal rigid corrugated pipe The inner surface of 2 is coated with an inner wall anti-corrosion layer 3, and the outer modified plastic pipe 1 and the inner metal rigid corrugated pipe 2 are heat-sealed. The outer layer modified plastic pipe 1 is a plastic pipe resistant to corrosion, high and low temperature, ultraviolet rays, embrittlement and impact. In this embodiment, the thickness of the inner metal rigid corrugated pipe 2 is not less than 2 mm, and the outer diameter is not less than 20 mm, while the thickness of the outer modified plastic pipe 1 is not less than 2 mm, because the inner metal rigid corrugated pipe 2 has a certain rigidity, so that the radial strength of this embodiment is large, and ca...

Embodiment 2

[0035] Such as Figure 4 , Figure 5 with Image 6 As shown, the difference between this embodiment and Embodiment 1 is that an intermediate adhesive layer 4 is also filled between the outer modified plastic pipe 1 and the inner metal rigid bellows 2, so that the outer The layer modified plastic pipe 1 and the inner metal rigid bellows 2 are closely pasted together to prevent air, rainwater, etc. The possibility that the inner metal rigid corrugated pipe 2 is corroded ensures its maximum service life.

[0036] The manufacturing method of the rigid corrugated composite pipe of this embodiment is as follows:

[0037] Step 1: Roll the metal rigid pipe into a corrugated pipe with a rolling machine to form the inner metal rigid corrugated pipe 2 .

[0038] Step 2: Use a glue injection machine to evenly coat the colloid on the outer surface of the inner metal rigid bellows 2, and fill up the corrugated depressions on the outer wall of the inner metal rigid bellows 2 to form the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com