Low-milk-source protein milk replacer for calves at ultra-early weaning period and preparation method of low-milk-source protein milk replacer for calves at ultra-early weaning period

A technology of early weaning and milk replacer, applied in animal feed, animal feed, application, etc., can solve the problems of poor production performance and low digestion and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

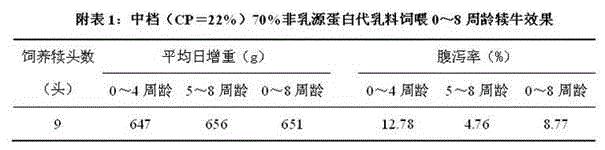

[0069] (2) Implementation example 2: Utilize a super-early-weaned calf low-milk source protein milk replacer formula (CP=24%) described in claim 1 to feed Chinese Holstein male calves, the specific implementation steps are as follows:

[0070] Step (1): Prepare premix A (according to the dosage ratio for preparing 100 kg milk replacer):

[0071] Calcium hydrogen phosphate 680.00 g sodium bicarbonate (baking soda) 450.00 g Sodium Sulfate (Sulfate) 215.40 g magnesium oxide 90.00 g Ferrous Sulfate Monohydrate 33.30 g Zinc Sulfate Monohydrate 14.50 g Manganese Sulfate Monohydrate 9.40 g Copper Sulfate Pentahydrate 3.20 g Calcium iodate with 5% iodine 1.00 g Cobalt chloride with 5% cobalt 0.20 g Sodium Selenite with 1% Selenium 3.00 g

[0072] Preparation method: first weigh calcium hydrogen phosphate and sodium bicarbonate into the pre-mixer, weigh in 4 g of vegetable oil during the stirring process, stir...

Embodiment 3

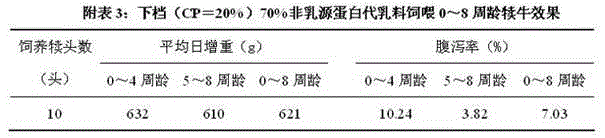

[0086] (3) Implementation example 3: Using the low-grade milk replacer formula (CP=20%) for ultra-early weaning of calves described in claim 1 to feed Chinese Holstein male calves, the specific implementation steps are as follows:

[0087] Step (1): Prepare premix A (according to the dosage ratio for preparing 100 kg milk replacer):

[0088] Calcium hydrogen phosphate 680.00 g sodium bicarbonate (baking soda) 450.00 g Sodium Sulfate (Sulfate) 215.40 g magnesium oxide 90.00 g Ferrous Sulfate Monohydrate 33.30 g Zinc Sulfate Monohydrate 14.50 g Manganese Sulfate Monohydrate 9.40 g Copper Sulfate Pentahydrate 3.20 g Calcium iodate with 5% iodine 1.00 g Cobalt chloride with 5% cobalt 0.20 g Sodium Selenite with 1% Selenium 3.00 g

[0089] Preparation method: first weigh calcium hydrogen phosphate and sodium bicarbonate into the pre-mixer, weigh in 4 g of vegetable oil during the stirring process, stir for 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com