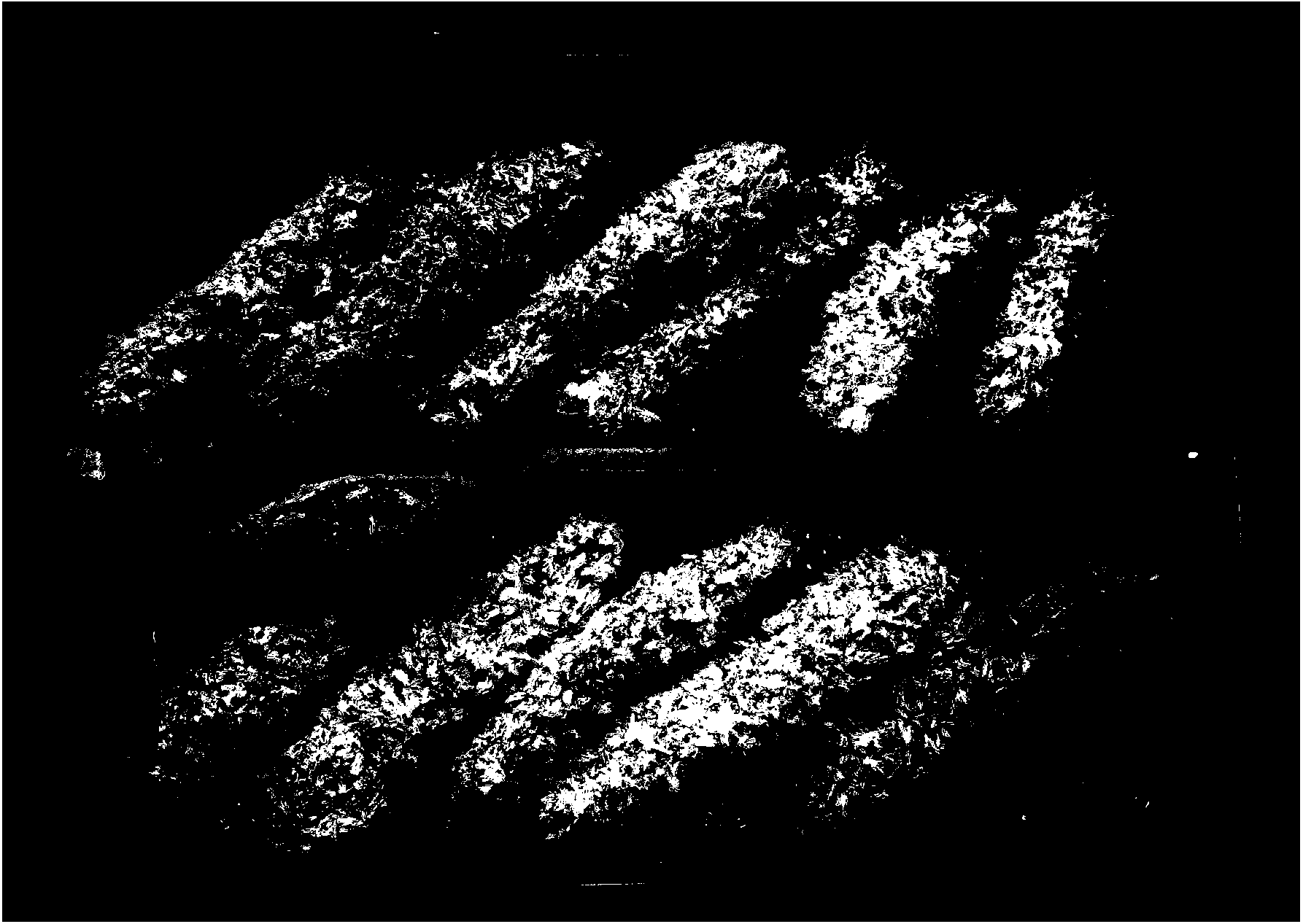

Preparation method of deep-fried crispy lotus root strips

A lotus root strips, crispy technology, applied in the field of preparation of fried crispy lotus root strips, can solve the problems of loss of crispy taste, oil-water infiltration and softening, loss of crispness, etc., and achieve the effect of not easy to oxidize and discolor, low production cost, and delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for deep-fried crispy lotus root strips, comprising the following steps:

[0025] 1) Take fresh lotus root, wash and peel it, and blanching it in hot water containing 0.2% (weight percent) gluconodelta lactone and 2% (weight percent) salt at a temperature of 95° C. for 1 minute, and cooling Then cut into lotus root strips.

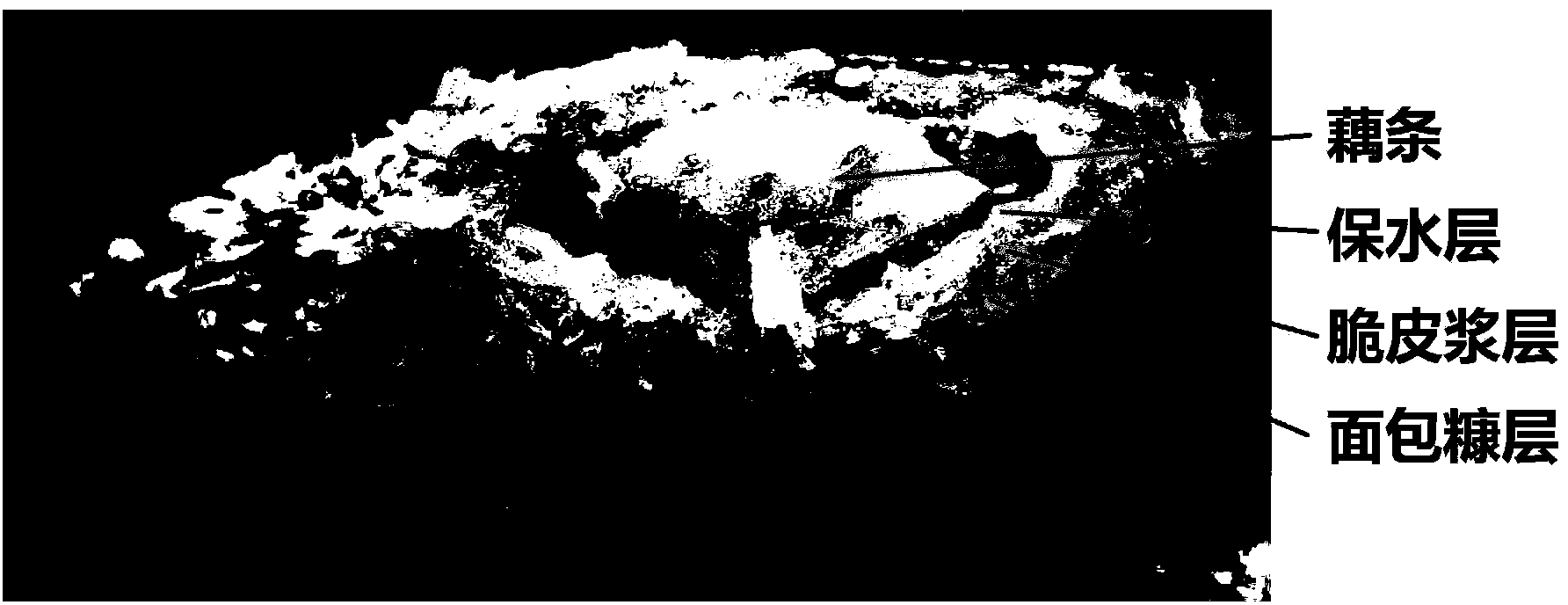

[0026] 2) After draining the surface water of the lotus root strips, use the gelatinized starch mucus layer on the surface of the lotus root strips to adhere to the water-retaining layer powder to form a water-proof layer on the surface of the lotus root strips.

[0027] The water-retaining layer powder is composed of the following components: 3g bleached shellac, 2g glucono delta lactone, 50g corn starch and 50g tapioca modified starch, the above components are ground and mixed at low temperature, and passed through a 200-mesh sieve.

[0028] 3) Hang the lotus root strips attached to the water-retaining layer powder with crisp...

Embodiment 2

[0031] A preparation method for deep-fried crispy lotus root strips, comprising the following steps:

[0032] 1) Fresh lotus root is taken, washed and peeled, blanched in hot water containing 0.5% glucono δ lactone and 0.5% salt for 2 minutes, cooled and cut into strips.

[0033] 2) After draining the surface water of the lotus root strips, use the gelatinized starch mucus layer on the surface of the lotus root strips to adhere to the water-retaining layer powder to form a water-proof layer on the surface of the lotus root strips.

[0034] The water-retaining layer powder is composed of the following components: 5g bleached shellac, 3g glucono delta lactone, 40 g Cornstarch and 30g of tapioca modified starch, the above-mentioned ingredients are ground and mixed at low temperature, and passed through a 200-mesh sieve.

[0035] 3) Hang the lotus root strips attached to the water-retaining layer powder with crispy paste, wrap in bread crumbs, fry, degrease, air-cool, and pack. ...

Embodiment 3

[0038] A preparation method for deep-fried crispy lotus root strips, comprising the following steps:

[0039] 1) Fresh lotus root is taken, washed and peeled, blanched in hot water containing 0.1% glucono δ lactone and 1% salt for 0.5 minutes, cooled and cut into strips.

[0040] 2) After draining the surface water of the lotus root strips, use the gelatinized starch mucus layer on the surface of the lotus root strips to adhere to the water-retaining layer powder to form a water-proof layer on the surface of the lotus root strips.

[0041] The water-retaining layer powder is composed of the following components: 1g bleached shellac, 5g glucono delta lactone, 30g cornstarch and 20g tapioca modified starch.

[0042] 3) Hang the lotus root strips attached to the water-retaining layer powder with crispy paste, wrap in bread crumbs, fry, degrease, air-cool, and pack. The frying temperature is 160-170°C for 20 seconds, and 0.5% citric acid and 0.1% liquor are added to the frying oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com