ZSM-35 molecular sieve and Me-ZSM-35 synthesis methods

A technology of ZSM-35 and synthesis method, which is applied in the direction of molecular sieve catalyst, chemical instrument and method, iron-conglomerate crystalline aluminum silicate zeolite, etc., can solve the problems of long reaction time, increase of synthesis cost, and increase of synthesis cost, and achieve The effect of large specific surface area and stability, reduced production energy consumption, and shortened crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Synthesis of ZSM-35 Molecular Sieve Using MCM-22 as Isomorphic Seed

[0039] First 0.10g of sodium metaaluminate was dissolved in deionized water, then 0.28g of sodium hydroxide was added thereto, and after a clear solution was formed, 5.62g of silica sol (SiO 2 Content is 28.5%), continue stirring at room temperature until forming a uniform silica-alumina gel, finally add 0.08g (for adding SiO 2 5% of the mass) MCM-22 molecular sieve and stir evenly; transfer the mixed raw materials to a stainless steel reactor with a polytetrafluoroethylene lining, and dynamically crystallize at 160 ° C for 12 hours. The molar ratio of the reaction raw materials is as follows: 45SiO 2 : 2.0NaAlO 2 : 11.8NaOH: 1035H 2O, the product was suction filtered and dried to obtain ZSM-35 molecular sieve, and the synthesis yield of the product was 86 wt%.

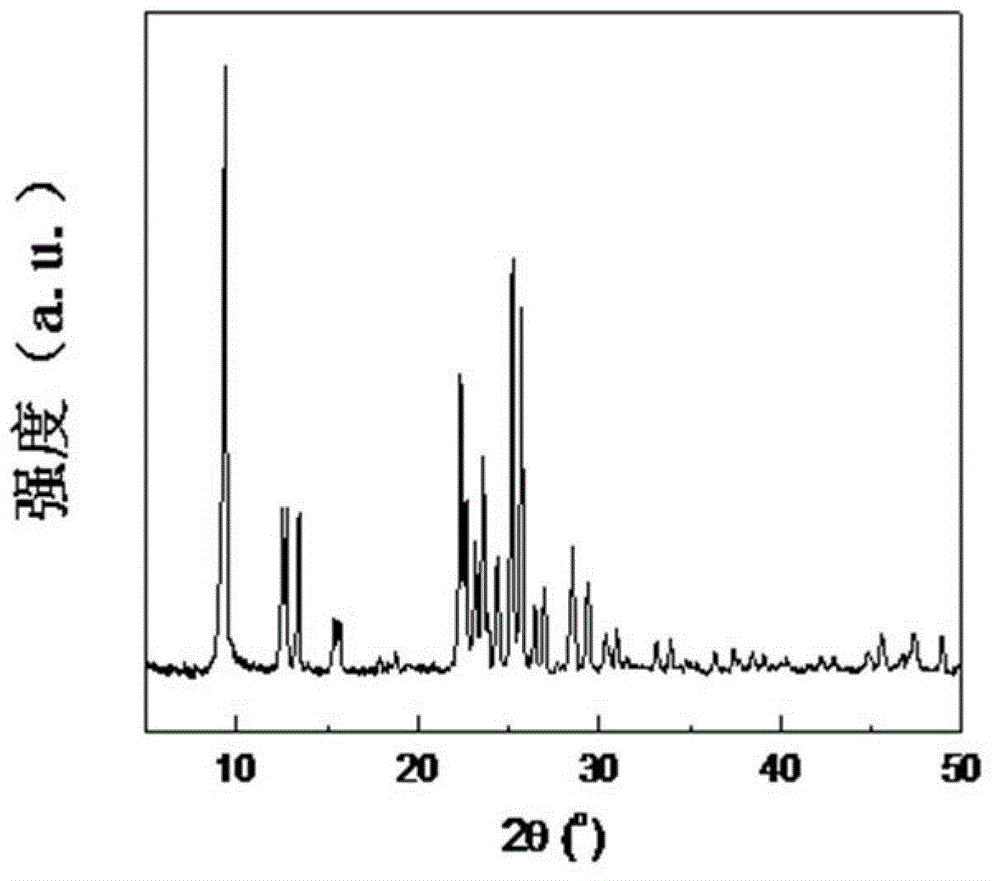

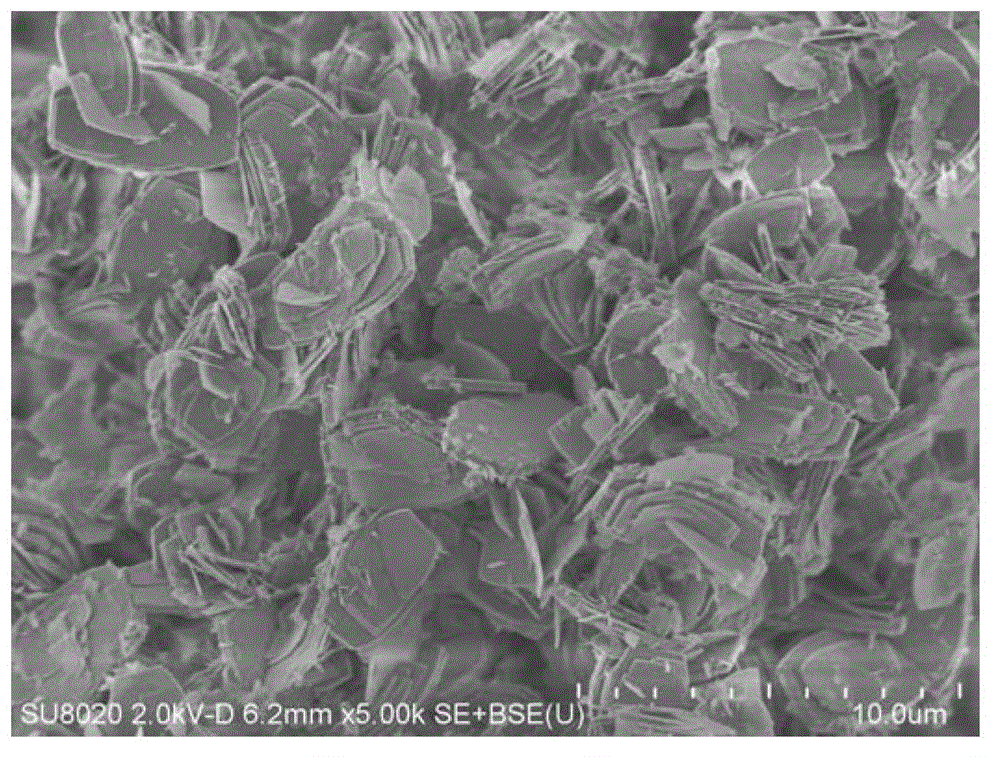

[0040] figure 1 It is the XRD pattern of the sample, it can be seen that the sample has a typical ZSM-35 zeolite molecular sieve structu...

Embodiment 2-18

[0045] The specific batching ratio and crystallization conditions are shown in Table 1, and the specific batching process is the same as in Example 1.

[0046] The synthetic samples were analyzed by XRD, and the data results were compared with figure 1 Close, that is, the diffraction peak position and shape are the same, and the relative peak intensity fluctuates in the range of ± 5% according to the change of synthesis conditions, indicating that the synthesized product has the characteristics of ZSM-35 structure, and the yield of the product is above 80wt%.

Embodiment 19

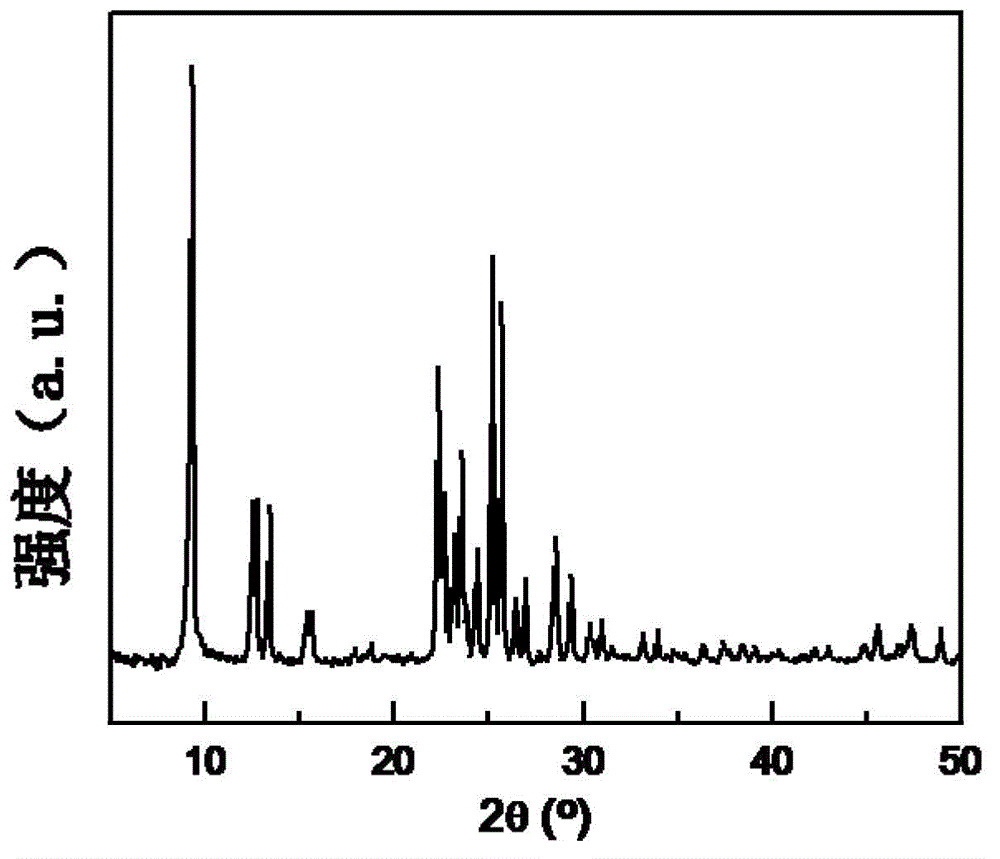

[0048] First 0.10g of sodium metaaluminate was dissolved in deionized water, then 0.28g of sodium hydroxide was added thereto, and after a clear solution was formed, 5.62g of silica sol (SiO 2 content is 28.5%), continue to stir at room temperature until a uniform silica-alumina gel is formed, then add 0.08g (for adding SiO 2 5% of the mass) MCM-49 molecular sieve and stir evenly; finally add 0.14g Fe(NO 3 ) 3 9H 2 The aqueous solution of O is stirred evenly, and the mixed raw materials are transferred to a stainless steel reactor with a polytetrafluoroethylene lining, and the dynamic crystallization is performed at 160°C for 20h. The molar ratio of the reaction raw materials is as follows: 45SiO 2 : 2.0NaAlO 2 : 11.8NaOH: 1035H 2 O:0.3Fe 2 o 3 , the product is suction filtered and dried to obtain Fe-ZSM-35 molecular sieve, the XRD spectrum is as follows image 3 Shown, the synthetic yield of product is 84wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com