High-abrasion-resistance sound insulation wood-plastic decorative sheet and continuous manufacturing method thereof

A decorative board, high wear-resistant technology, applied in the direction of chemical instruments and methods, building structures, layered products, etc., can solve the problems of uncontinuous production, time-consuming and labor-intensive processes, complicated production processes, etc., to improve clarity , Improve production efficiency and reduce the effect of secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

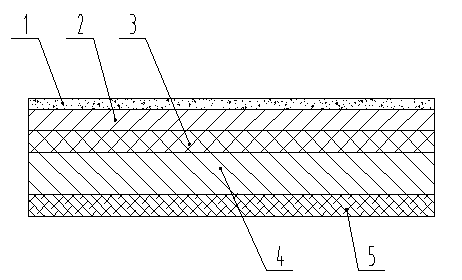

[0045] High wear-resistant and sound-insulating wood-plastic decorative board, soft wood-plastic foam shock-absorbing and sound-insulating layer 5 from bottom to top, hard wood-plastic foam layer 4, thermal transfer pattern layer 3, and extrusion coating wear-resistant layer 2. The UV coating 1 is compounded; the soft wood-plastic foam shock-absorbing and sound-insulating layer 5 is a soft PVC wood-plastic foam layer, and the hard wood-plastic foam layer 4 is a hard PVC wood-plastic foam layer; Quality wood-plastic foam shock-absorbing and sound-insulating layer 5 and hard wood-plastic foam layer 4 are combined to form a soft and hard co-extruded wood-plastic foam layer, and the soft and hard co-extruded wood-plastic foam layer is a soft PVC wood-plastic foam layer and Composite structure made of soft and hard co-extrusion foaming of rigid PVC wood-plastic foam layer.

[0046] Weigh according to the formula ratio of soft PVC wood-plastic foam layer: 100 parts of polyvinyl chlo...

Embodiment 2

[0049] High wear-resistant and sound-insulating wood-plastic decorative board, soft wood-plastic foam shock-absorbing and sound-insulating layer 5 from bottom to top, hard wood-plastic foam layer 4, thermal transfer pattern layer 3, and extrusion coating wear-resistant layer 2. The UV coating 1 is compounded; the soft wood-plastic foam shock-absorbing and sound-insulating layer 5 is a soft PVC wood-plastic foam layer, and the hard wood-plastic foam layer 4 is a hard PVC wood-plastic foam layer; Quality wood-plastic foam shock-absorbing and sound-insulating layer 5 and hard wood-plastic foam layer 4 are combined to form a soft and hard co-extruded wood-plastic foam layer, and the soft and hard co-extruded wood-plastic foam layer is a soft PVC wood-plastic foam layer and Composite structure made of soft and hard co-extrusion foaming of rigid PVC wood-plastic foam layer.

[0050] Weigh according to the formula ratio of soft PVC wood-plastic foam layer: 100 parts of polyvinyl chlo...

Embodiment 3

[0053] High wear-resistant and sound-insulating wood-plastic decorative board, soft wood-plastic foam shock-absorbing and sound-insulating layer 5 from bottom to top, hard wood-plastic foam layer 4, thermal transfer pattern layer 3, and extrusion coating wear-resistant layer 2. The UV coating 1 is compounded; the soft wood-plastic foamed shock-absorbing and sound-insulating layer 5 is an XPE layer, and the hard wood-plastic foamed layer 4 is a PE wood-plastic foamed layer; the soft wood-plastic foamed shock-absorbing and sound-insulating layer Layer 5 and hard wood-plastic foam layer 4 are combined to form a soft-hard co-extruded wood-plastic foam layer; the soft-hard co-extruded wood-plastic foam layer is a composite structure formed by co-extruding an XPE layer and a PE wood-plastic foam layer.

[0054] Weigh according to the XPE layer formula ratio: 100 parts of low-density polyethylene (LDPE) resin, 1 part of wood powder or other plant fiber, 4 parts of ADC foaming agent, 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com