Flexible temperature sensor based on graphene nanometer wall and preparing method thereof

A graphene nano wall and temperature sensor technology, applied in the field of sensors, can solve the problems of non-flexible biocompatibility, poor biocompatibility, etc., and achieve the effects of good biocompatibility, convenient processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

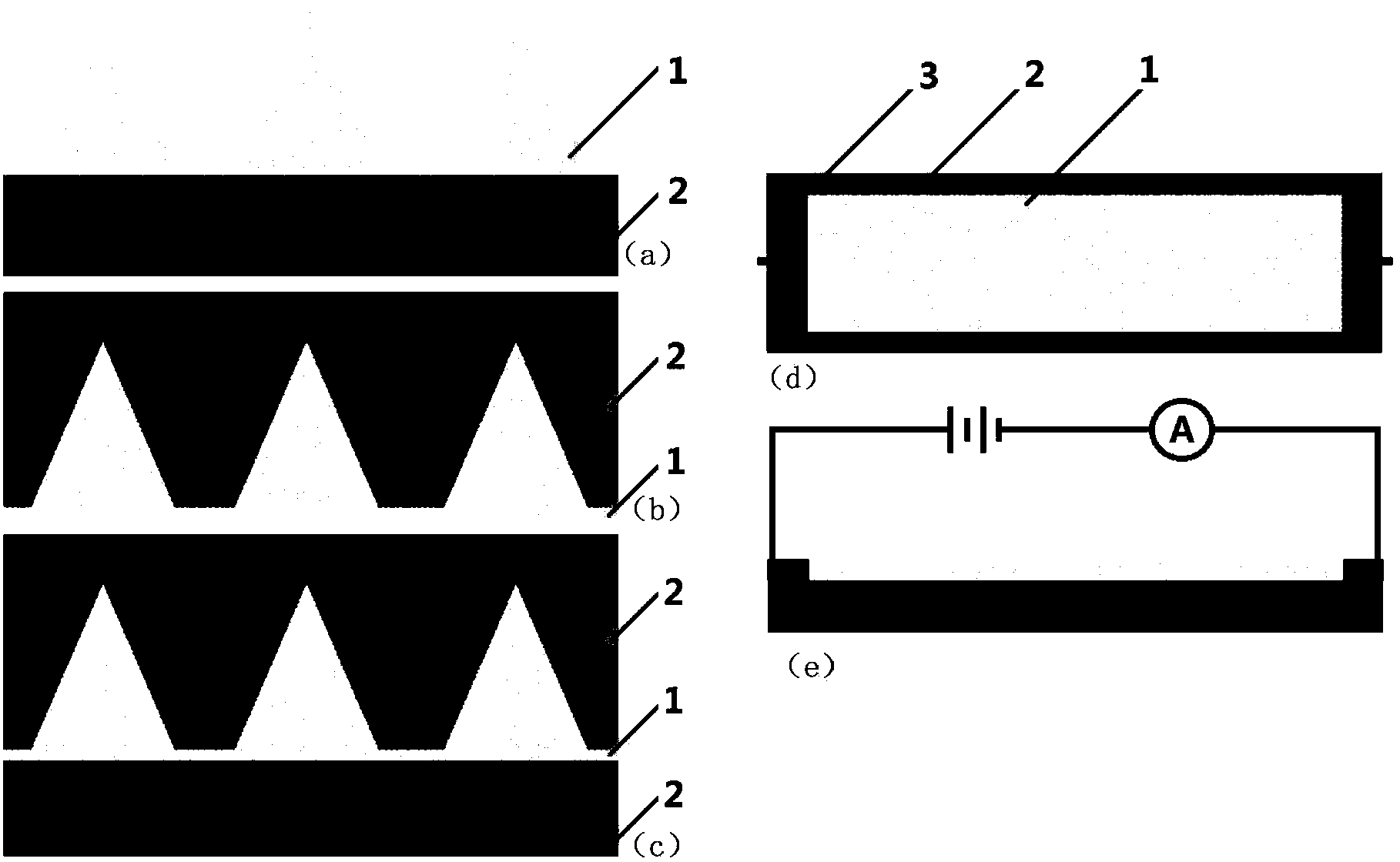

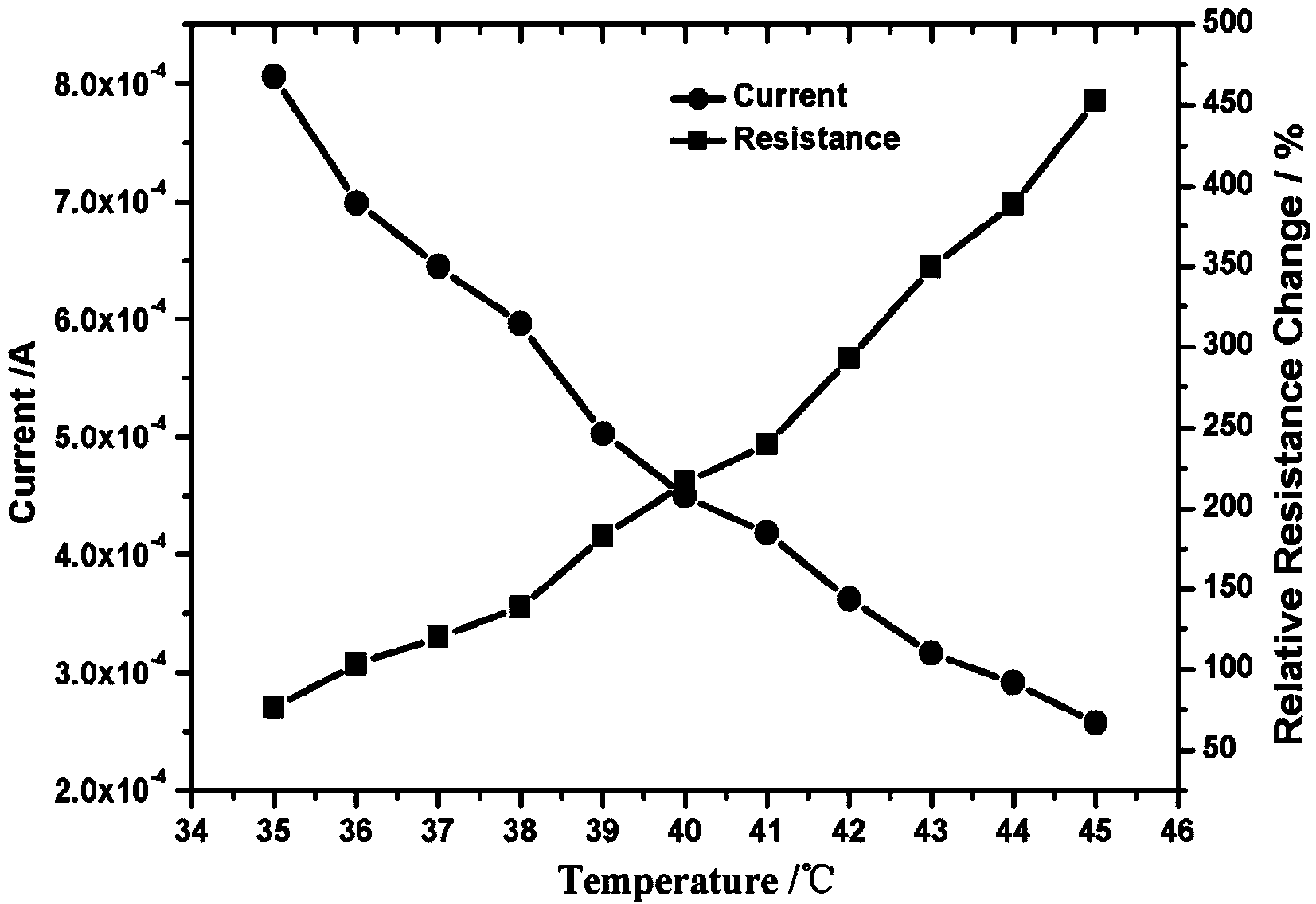

[0044] Example 1: Fabrication of a graphene nanowall / PDMS composite material temperature sensor and testing of its sensing characteristics

[0045] Step 1: Preparation of graphene nanowalls

[0046] First place the substrate copper foil in acetone, 95vol% ethanol, and pure water for ultrasonic cleaning for 2 minutes, blow dry with nitrogen, and then place it in the vacuum chamber of the tubular CVD system to prepare graphene nanowalls to obtain graphene nanometer walls. wall.

[0047] Step 2: Fabrication of thermal resistors for flexible temperature sensors based on graphene nanowalls

[0048] Put the obtained graphene nano-wall in the ferric nitrate corrosion solution to completely remove the copper, then use the prepared PDMS with a thickness of 50um to pick up and combine the graphene nano-wall from below, and then use the obtained structure. Repeated cleaning with ionized water, hydrochloric acid, etc., and drying with nitrogen gas to obtain a graphene nanowall / polymer (...

Embodiment 2

[0053] Example 2: Fabrication of PDMS / graphene nano-wall composite temperature sensor and testing of its sensing characteristics

[0054] Step 1: Preparation of graphene nanowalls

[0055] First place the substrate copper foil in acetone, 95vol% ethanol, and pure water for ultrasonic cleaning for 2 minutes, blow dry with nitrogen, and then place it in the vacuum chamber of the tubular CVD system to prepare graphene nanowalls to obtain graphene nanometer walls. wall.

[0056] Step 2: Fabrication of thermal resistors for flexible temperature sensors based on graphene nanowalls

[0057] The resulting graphene nanowall was spin-coated with a layer of PDMS with a thickness of 50 um, and placed in an oven at 80°C to cure the PDMS to obtain a PDMS / graphene nanowall / two-dimensional copper structure. The resulting structure is repeatedly cleaned with deionized water, hydrochloric acid, etc., and dried with nitrogen to obtain a temperature sensor with a two-layer structure of PDMS / gra...

Embodiment 3

[0062] Example 3: Fabrication of PDMS / graphene nano-wall / PDMS composite material temperature sensor and testing of its sensing characteristics

[0063] Step 1: Preparation of graphene nanowalls

[0064] First place the substrate copper foil in acetone, 95vol% ethanol, and pure water for ultrasonic cleaning for 2 minutes, blow dry with nitrogen, and then place it in the vacuum chamber of the tubular CVD system to prepare graphene nanowalls to obtain graphene nanometer walls. wall.

[0065] Step 2: Fabrication of thermal resistors for flexible temperature sensors based on graphene nanowalls

[0066] The resulting graphene nanowall was spin-coated with a layer of PDMS with a thickness of 50 um, and placed in an oven at 80°C to cure the PDMS to obtain a PDMS / graphene nanowall / two-dimensional copper structure. Then the resulting structure was repeatedly cleaned with deionized water, hydrochloric acid, etc., and dried with nitrogen gas to obtain a two-layer structure of PDMS / graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com