Method for achieving remote control and maintenance assembly sequence planning of parts in radiation environment

A technology for assembly sequence planning and remote maintenance, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of combinatorial explosion, insufficient expansion of solution space, and low search efficiency, so as to improve efficiency and quality, Improvement effect of premature convergence phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

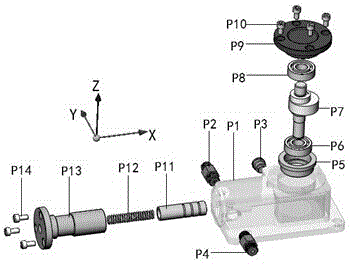

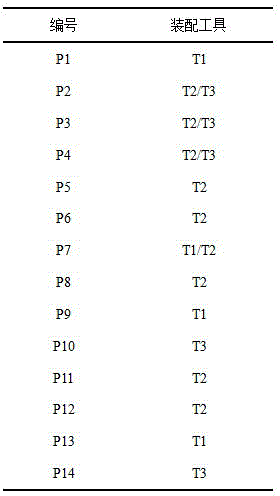

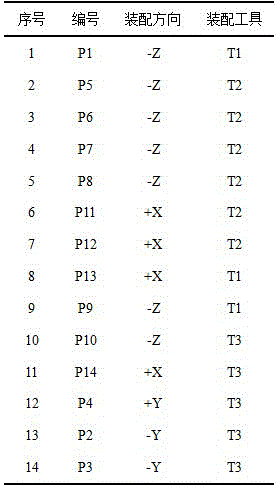

[0040] An assembly sequence planning method for parts remote maintenance maintenance in a radiation environment, the parts are installed in the radiation environment, and parts assembly is realized through remote maintenance, characterized in that the assembly sequence planning method is based on an adaptive mutation particle swarm optimization algorithm , the assembly sequence planning method mainly includes the following steps:

[0041] Step 1. First establish an interference matrix to describe the interference relationship between the parts to be assembled in the general assembly and other parts in the direction of ±x, ±y, and ±z of the Cartesian coordinate system, so as to judge the feasibility of the assembly sequence;

[0042] The interference matrix is A, and parts are represented by P, and the assembly consists of n parts {P 1 , P 2 ,...,P n} composition, let the element I of the interference matrix ijx , I ijy and I ijz for part P i When assembled along the +x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com