A cascaded heating system for preheating the inlet material of the gas fractionation tower

A gas fractionation and cascade heating technology, applied in fractionation, hydrocarbon distillation, distillation regulation/control, etc., can solve problems such as unreasonable energy utilization, increased entropy in heating links, large heat exchange temperature difference, etc., to improve energy utilization efficiency, The effect of reducing consumption and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

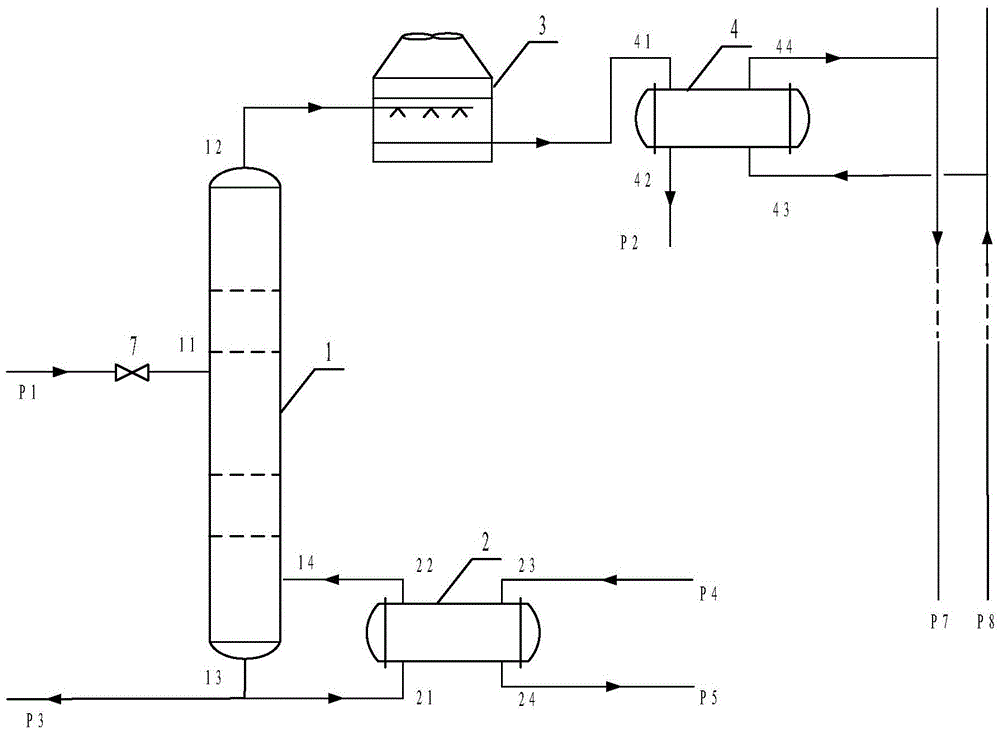

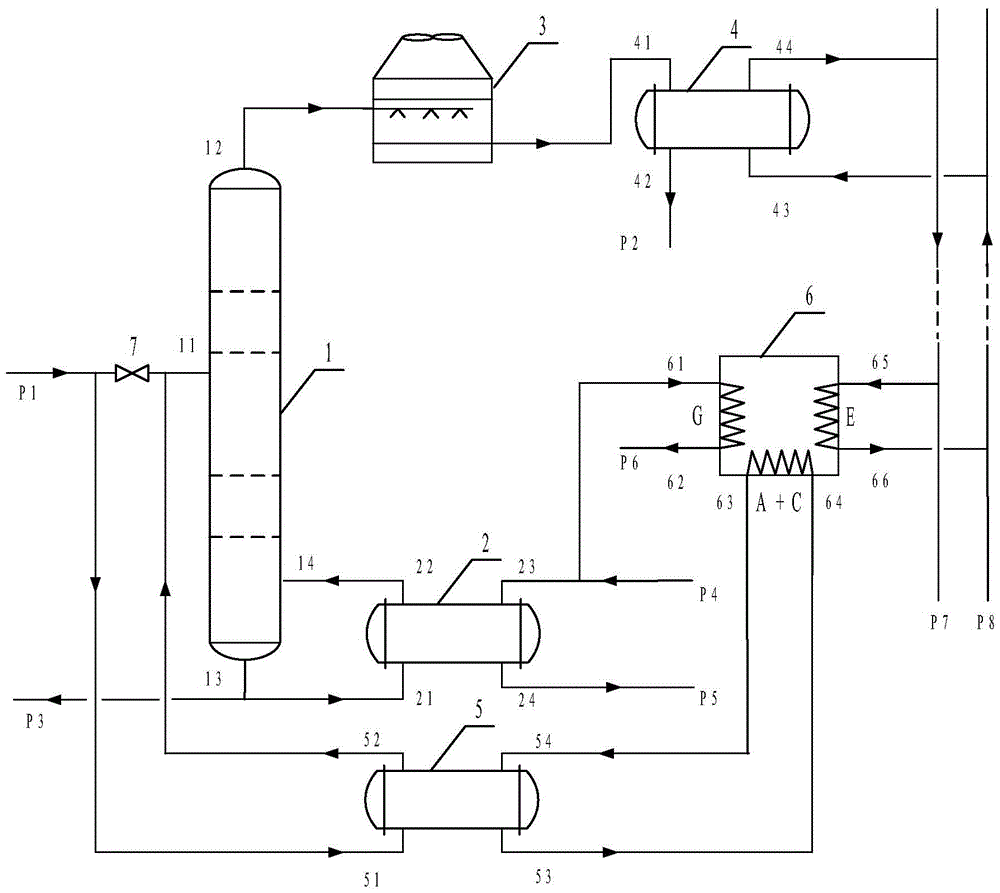

[0017] exist figure 2 In the shown flow process 2, the material inlet pipeline P1 is connected with the material side inlet 51 of the hot water / material heat exchanger 5 and the inlet of the valve 7 respectively, and the material inlet 11 of the fractionation column 1 is connected with the outlet of the valve 7 and the hot water / material inlet 11 respectively. The material side outlet 52 of the material heat exchanger 5 is connected, the high-temperature product material outlet 12 at the top of the fractionating tower 1 is connected with the inlet of the air cooler, the finished product material at the bottom of the fractionating tower 1 is connected to the bottom product outlet pipeline P3, and the bottom of the fractionating tower 1 The material outlet 13 is connected to the low-temperature side inlet 21 of the reboiler 2, and the material inlet 14 of the bottom of the fractionation tower 1 is connected to the low-temperature side outlet 22 of the reboiler 2; the outlet of t...

Embodiment 2

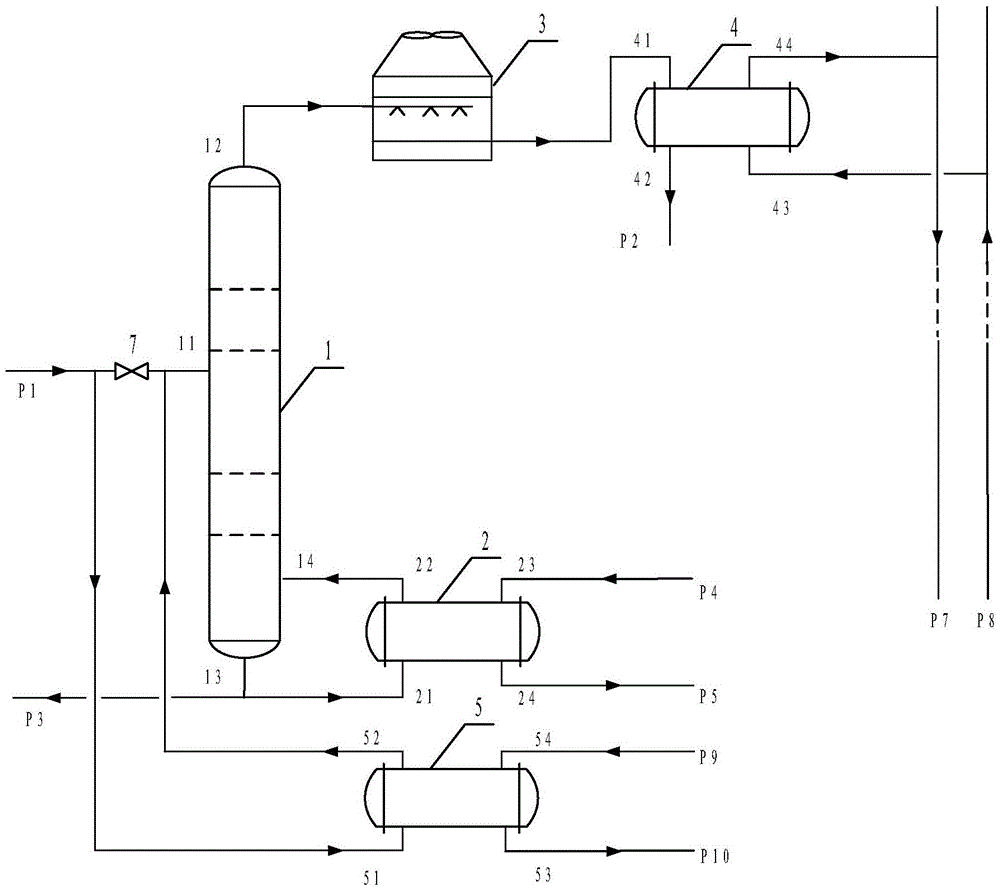

[0021] If other processes in the petroleum refinery (such as atmospheric and vacuum, catalytic cracking) produce surplus heat-combined waste heat heat medium water with a grade lower than process steam, the steam-type lithium bromide absorption heat pump can be replaced by heat-combined heat medium water circulation pipeline P9 , P10, as the heat source of the hot water / material heat exchanger, other connection methods and working principles are the same as in Embodiment 1, and its process is as follows image 3 shown.

[0022] The newly added hot water / material heat exchanger 5, steam-type lithium bromide absorption heat pump 6 and valve 7 in the present invention are all mature products. The specific implementation of each device is described as follows:

[0023] 1. Fractionation tower, determined according to the material production volume, is a common equipment;

[0024] 2. Reboiler, determined according to the material production volume, feed temperature and material te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com