Inorganic ferrotitanium polymeric coagulant with ilmenite as raw material and preparation technology thereof

A technology of ilmenite and coagulant, which is applied in the field of water treatment to achieve the effect of reducing preparation cost and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

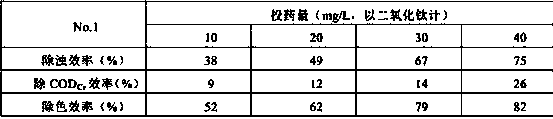

Embodiment 1

[0028] Crush the ilmenite into powder. Heat 15mL of concentrated sulfuric acid solution to 120°C~150°C, the mass fraction of concentrated sulfuric acid solution is 75%, and then add 10kg of powdered ilmenite to the In the above concentrated sulfuric acid solution, continue to heat to 170°C~190°C, react for 1 minute to 5 minutes, then cool to 100°C~110°C to obtain a foamy solidified product for later use. Add 20mL of dilute sulfuric acid solution to the above-mentioned foamy cured product, the mass fraction of the dilute sulfuric acid solution is 20%, start stirring after 1 minute to 3 minutes, the stirring speed is 50 rpm to 80 rpm, and the reaction time is controlled For 10 minutes to 20 minutes, obtain a suspension, filter to obtain a leaching solution, and set aside. At a stirring speed of 150 rpm to 350 rpm, 13 mL of sodium hydroxide solution was added to the above leaching solution to obtain a mixed solution. The molar fraction of the sodium hydroxide solution was 17 mol...

Embodiment 2

[0030] Crush the ilmenite into powder. Heat 15mL of concentrated sulfuric acid solution to 120°C~150°C, the mass fraction of concentrated sulfuric acid solution is 75%, and then add 10kg of powdered ilmenite to the In the above concentrated sulfuric acid solution, continue to heat to 170°C~190°C, react for 1 minute to 5 minutes, then cool to 100°C~110°C to obtain a foamy solidified product for later use. Add 30mL of dilute sulfuric acid solution to the above-mentioned foamy cured product, the mass fraction of the dilute sulfuric acid solution is 30%, start stirring after 1 minute to 3 minutes, the stirring speed is 50 rpm to 80 rpm, and the reaction time is controlled For 10 minutes to 20 minutes, obtain a suspension, filter to obtain a leaching solution, and set aside. At a stirring speed of 150 rpm to 350 rpm, 18 mL of sodium hydroxide solution was added to the above leaching solution to obtain a mixed solution. The molar fraction of the sodium hydroxide solution was 19 mol / L...

Embodiment 3

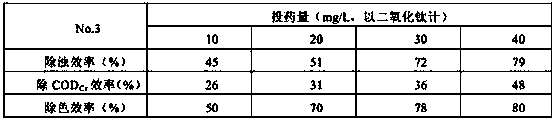

[0032] Crush the ilmenite into powder. Heat 15mL of concentrated sulfuric acid solution to 120°C~150°C, the mass fraction of concentrated sulfuric acid solution is 75%, and then add 10kg of powdered ilmenite to the In the above concentrated sulfuric acid solution, continue to heat to 170°C~190°C, react for 1 minute to 5 minutes, then cool to 100°C~110°C to obtain a foamy solidified product for later use. Add 20mL of dilute sulfuric acid solution to the above-mentioned foamy cured product, the mass fraction of the dilute sulfuric acid solution is 40%, start stirring after 1 minute to 3 minutes, the stirring speed is 50 rpm to 80 rpm, and the reaction time is controlled For 10 minutes to 20 minutes, obtain a suspension, filter to obtain a leaching solution, and set aside. At a stirring speed of 150 rpm to 350 rpm, 25 mL of sodium hydroxide solution was added to the above leaching solution to obtain a mixed solution. The molar fraction of the sodium hydroxide solution was 16 mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mole fraction | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com