Method for synthesizing tricyclodecanedimethanol

A technology of decanedimethanol and dicyclopentadiene is applied in the field of synthesizing tricyclodecanedimethanol and achieves the effects of easy separation, simple preparation process and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

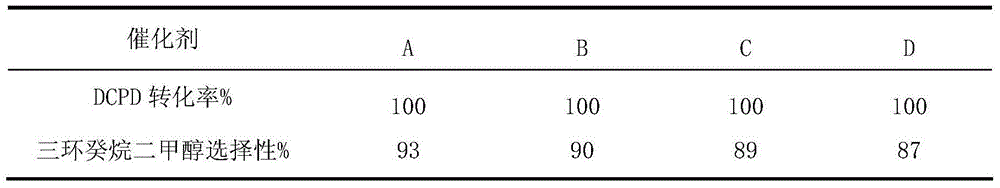

Examples

Embodiment 1

[0022] Preparation of silica-supported cobalt-rhodium-copper trimetallic catalyst:

[0023] a. Dissolve 20ml of tetraethyl orthosilicate in 14ml of ethanol, and heat to a temperature of 60°C under stirring to obtain a mixed solution;

[0024] b. Dissolve 3g of copper nitrate, 0.3g of cobalt chloride and 0.3g of rhodium trichloride in 10ml of distilled water, add the mixed solution obtained in step a, then add the mixed solution of 5ml of concentrated nitric acid and 5ml of water, and age at a temperature of 60°C 24 hours, then baked at 400°C for 6 hours in an air atmosphere in a muffle furnace to obtain silica-supported cobalt-rhodium copper oxides; then the obtained silica-supported cobalt-rhodium copper oxides in hydrogen Reduction at a temperature of 400°C for 4 hours, cooling to room temperature, calcination at a temperature of 400°C in air for 6 hours, and reduction at a temperature of 400°C in hydrogen for 4 hours to obtain a silica-supported cobalt-rhodium-copper cataly...

Embodiment 2

[0030] Preparation of silica-supported cobalt-rhodium-copper trimetallic catalyst:

[0031] a. Dissolve 20ml of ethyl orthosilicate in 14ml of ethanol, and heat to a temperature of 80°C under stirring to obtain a mixed solution;

[0032] b. Dissolve 3g of copper nitrate, 0.3g of cobalt chloride and 0.3g of rhodium trichloride in 10ml of distilled water, add the mixed solution obtained in step a, then add the mixed solution of 5ml of concentrated nitric acid and 5ml of water, and age at a temperature of 80°C 72 hours, then baked at 600°C for 3 hours in an air atmosphere in a muffle furnace to obtain silica-supported cobalt-rhodium copper oxides; then the obtained silica-supported cobalt-rhodium copper oxides in hydrogen Reduction at 600°C for 2 hours, cooling to room temperature, calcination at 600°C in air for 3 hours, reduction at 600°C in hydrogen for 2 hours, to obtain a silica-supported cobalt-rhodium-copper catalyst;

[0033] Phosphine ligand-modified silica-supported co...

Embodiment 3

[0038] Preparation of silica-supported cobalt-rhodium-copper trimetallic catalyst:

[0039] a. Dissolve 20ml of tetraethyl orthosilicate in 14ml of ethanol, and heat to a temperature of 70°C under stirring conditions to obtain a mixed solution;

[0040] b. Dissolve 3g of copper nitrate, 0.3g of cobalt chloride and 0.3g of rhodium trichloride in 10ml of distilled water, add the mixed solution obtained in step a, then add the mixed solution of 5ml of concentrated nitric acid and 5ml of water, and age at a temperature of 70°C 48 hours, then baked at 500° C. for 4 hours in an air atmosphere in a muffle furnace to obtain silica-supported cobalt-rhodium copper oxides, and then the obtained silica-supported cobalt-rhodium copper oxides in hydrogen Reduction at a temperature of 500°C for 3 hours, cooling to room temperature, calcination at a temperature of 500°C in air for 4 hours, and reduction at a temperature of 500°C in hydrogen for 3 hours to obtain a silica-supported cobalt-rhod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com