Pre-stressed steel strand slow-binding agent with good heat resistance and 18-month curing time

A prestressed steel strand, heat-resistant performance technology, applied in the field of slow binder, prestressed steel strand slow binder, can solve the problems of inability to accommodate fillers, shortened pot life, inconvenient operation, etc., to achieve enhanced Toughness, reduced volatility, and increased curing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

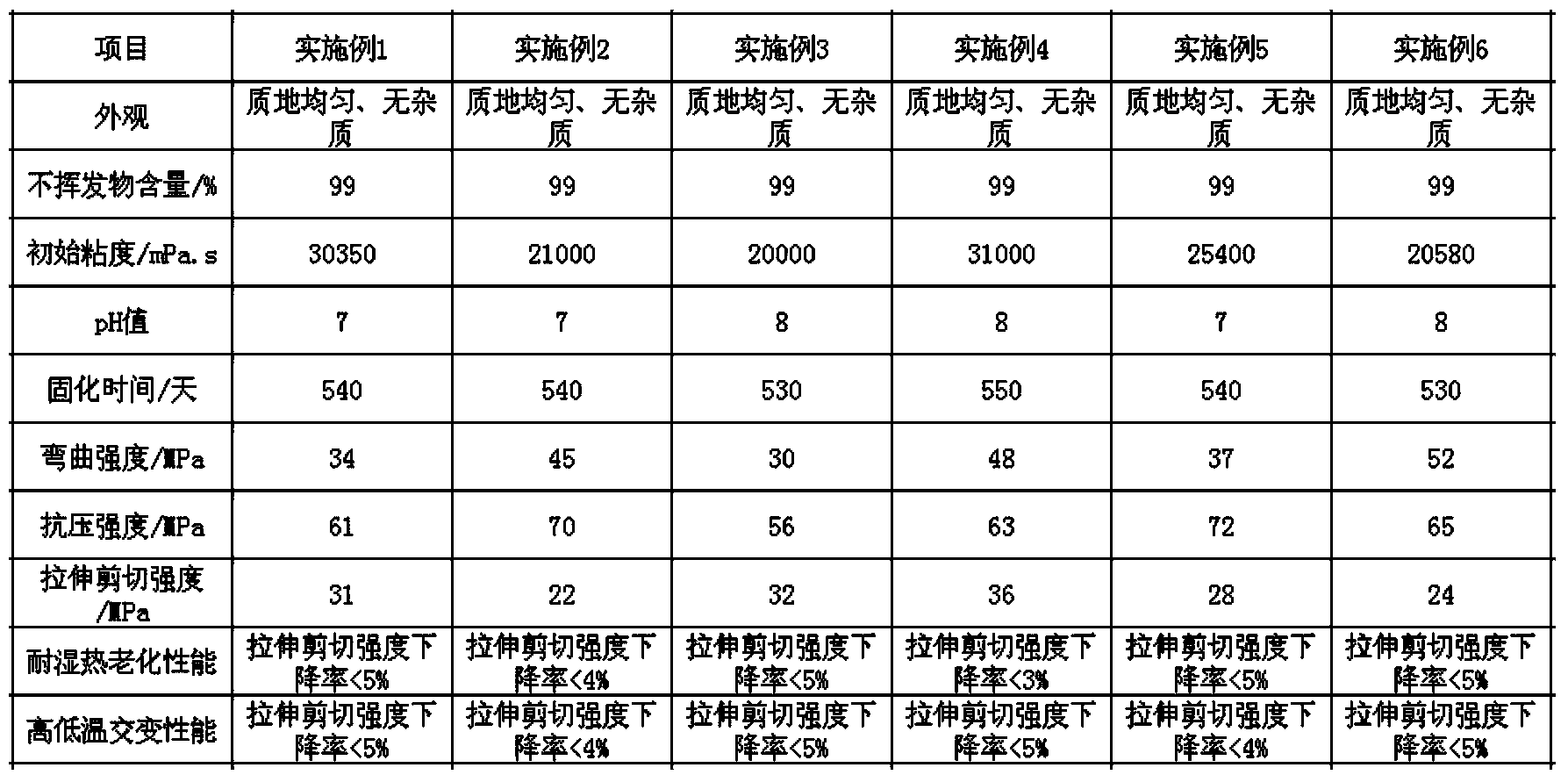

Examples

preparation example Construction

[0046] The preparation method of this slow binding agent is:

[0047]Put each component of the slow binder into the reaction kettle one by one, stir at 30-40°C for about 10-20 minutes, and mix evenly.

Embodiment 1

[0049] Bisphenol A epoxy resin (E51) 100KG, non-reactive diluent ethyl acetate 5KG, curing agent (modified DDM and phenalkamine mixed at a mass ratio of 2:3) 7KG, filler nano-calcium carbonate 50KG.

Embodiment 2

[0051] Bisphenol A epoxy resin (E51) 100KG, inactive diluent (butyl acetate and dibutyl phthalate mixed at a mass ratio of 1:2) 10KG, curing agent (modified DDS, phenalkamine and polyetheramine According to the mass ratio of 2:3:1 mixed) 8KG, the filler is nano-calcium carbonate 50KG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com