Method for processing double-beam laser cladding tool

A technology of laser cladding and processing method, which is applied in the processing field of double-beam laser cladding tools, can solve the problems of deformation of tool base material, easy fracture of cladding layer, influence of tool appearance, etc., and achieves a high degree of automation, dense organization, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

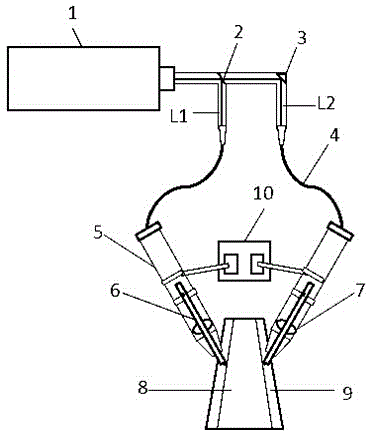

[0016] Such as figure 1 As shown, the iron-based alloy Fe62 coating is prepared on the surface of No. 45 steel as the base material of the tool by double-beam laser cladding. The coating has a width of 6 mm and a thickness of 1.48 mm.

[0017] 1. Use a grinding machine to derust the surface of the base material 8 of No. 45 steel, and then wipe the surface with industrial alcohol with a concentration of 99% to remove oil.

[0018] 2. Using a laser beam splitter 2 with a fixed beam splitting ratio of 50%:50%, a beam of laser light emitted by an all-solid-state fiber laser 1 is divided into two beams of L1 and L2. The L2 laser is reflected by the total reflection mirror 3. L1, L2 two laser beams pass through the optical fiber 4, the laser head 5 fixed on the mechanical arm 10, and the focusing lens 7 with a focal length of 200mm, and then act on the tool substrate 8. The laser power is set to 2800W, and the energy at L1 and L2 is distributed. They are 1400W respectively, the ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com