Jean-pollution-preventing PVC artificial leather and preparation method thereof

A technology of artificial leather and denim, which is applied in the field of automotive interior materials, can solve the problems of low pollution resistance, unfriendly environment, light resistance, low temperature resistance flexibility and poor flame retardancy performance indicators, and achieve flame retardant performance. Good, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

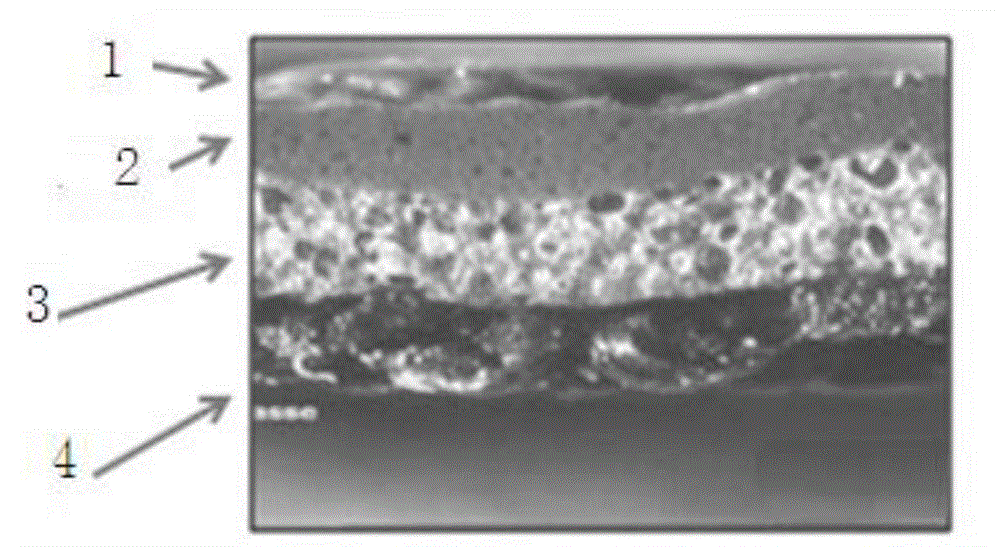

[0030] The first step: Weigh the raw materials according to the ratio of various materials in the formula, the ratio of PVC to plasticizer is 100:80-100, and then mix the raw materials evenly, including: 50 parts of PVC resin, 50 parts of plasticizer, 6 parts of low-volatility stabilizer, 10 parts of colorant; water-based paint is coated on the surface of the base layer, the formula of the water-based paint includes: 80 parts of water-based polyurethane modified resin, 8 parts of auxiliary agents.

[0031] Among them, the above-mentioned plasticizer is a low-volatility linear polymer plasticizer, the above-mentioned low-volatility stabilizer is a compound epoxy zinc stabilizer, the above-mentioned color material includes chromium antimony titanium yellow, iron red or titanium dioxide, and the above-mentioned water-based additives include wetting additives, defoaming aids or thickening aids.

[0032] In this embodiment, the above-mentioned low-volatile linear polymer plasticize...

Embodiment 2

[0040] The first step: Weigh the raw materials according to the ratio of various materials in the formula. The ratio of PVC to plasticizer is 100:80-100, and then mix the raw materials evenly, 70 parts of PVC resin, 60 parts of plasticizer, 2 parts low-volatility stabilizer, 15 parts of colorants; the surface of the base layer is coated with water-based paint, and the formula of the water-based paint includes: 70 parts of water-based polyurethane modified resins, and 20 parts of auxiliary agents.

[0041] Among them, the above-mentioned plasticizer is a low-volatility linear polymer plasticizer, the above-mentioned low-volatility stabilizer is a compound epoxy zinc stabilizer, the above-mentioned color material includes chromium antimony titanium yellow, iron red or titanium dioxide, and the above-mentioned water-based additives include wetting additives, defoaming aids or thickening aids.

[0042] In this embodiment, the above-mentioned low-volatile linear polymer plasticizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com