Thin film composite membrane structures

A composite membrane, thin film technology, applied in membrane, membrane technology, semi-permeable membrane separation and other directions, can solve problems such as high cost and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

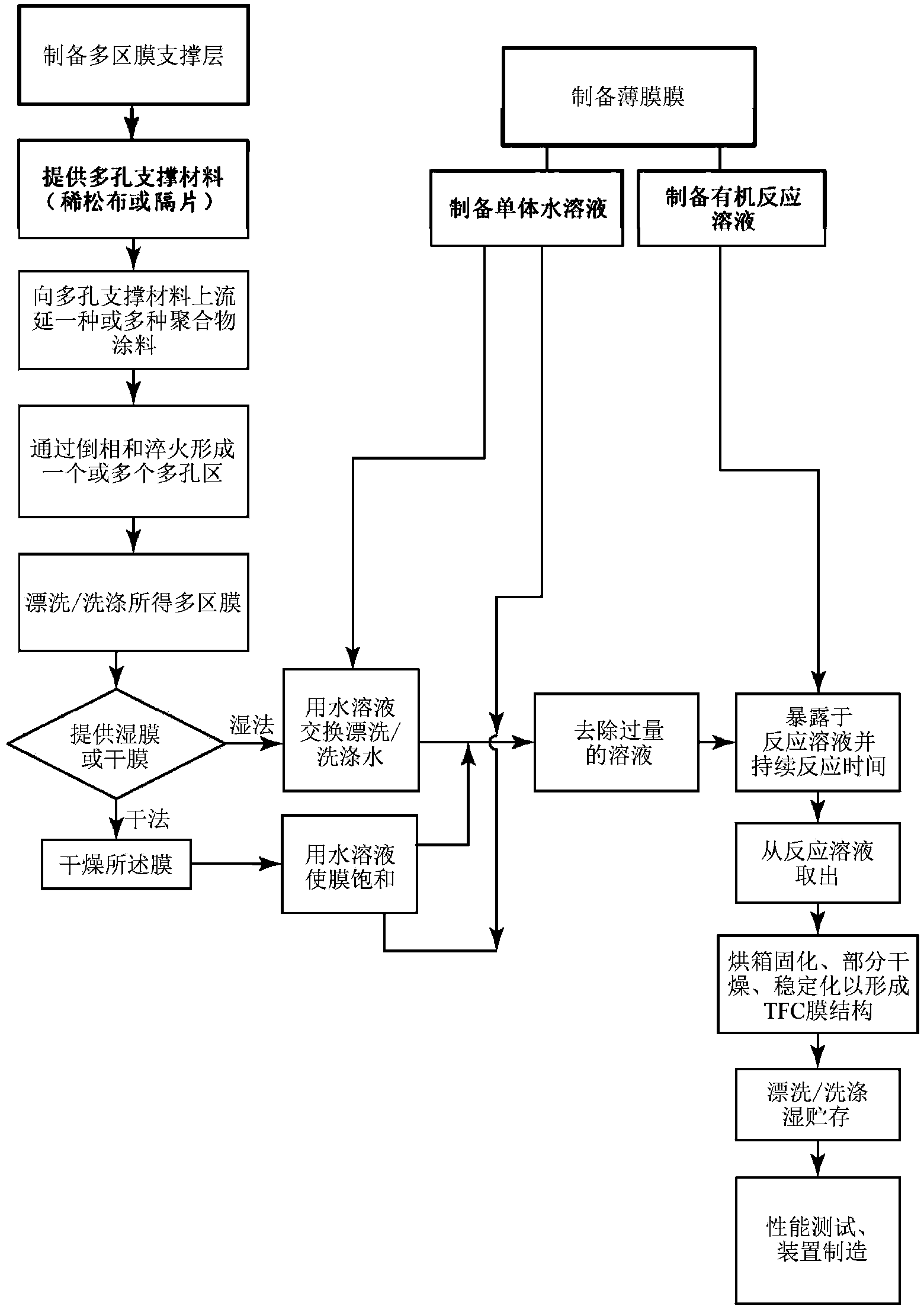

[0077] The procedure demonstrating the fabrication of these TFC membrane structures by PIP-based interfacial polymerization of polyamides is as follows:

[0078]The monomers used for this in situ interfacial polymerization of poly(piperazinamide) are PIP and TMC. PIP was dissolved in Milli-Q water at different concentrations ranging from 0.25% to 3% (w / v). To the aqueous PIP solution was added triethylamine (TEA) in a weight ratio of 1 / 1 relative to the amount of PIP. A 0.15% (w / v) trimesoyl chloride (TMC) / hexane solution was prepared. Both solutions were stirred at room temperature for a minimum of 3 hours before use.

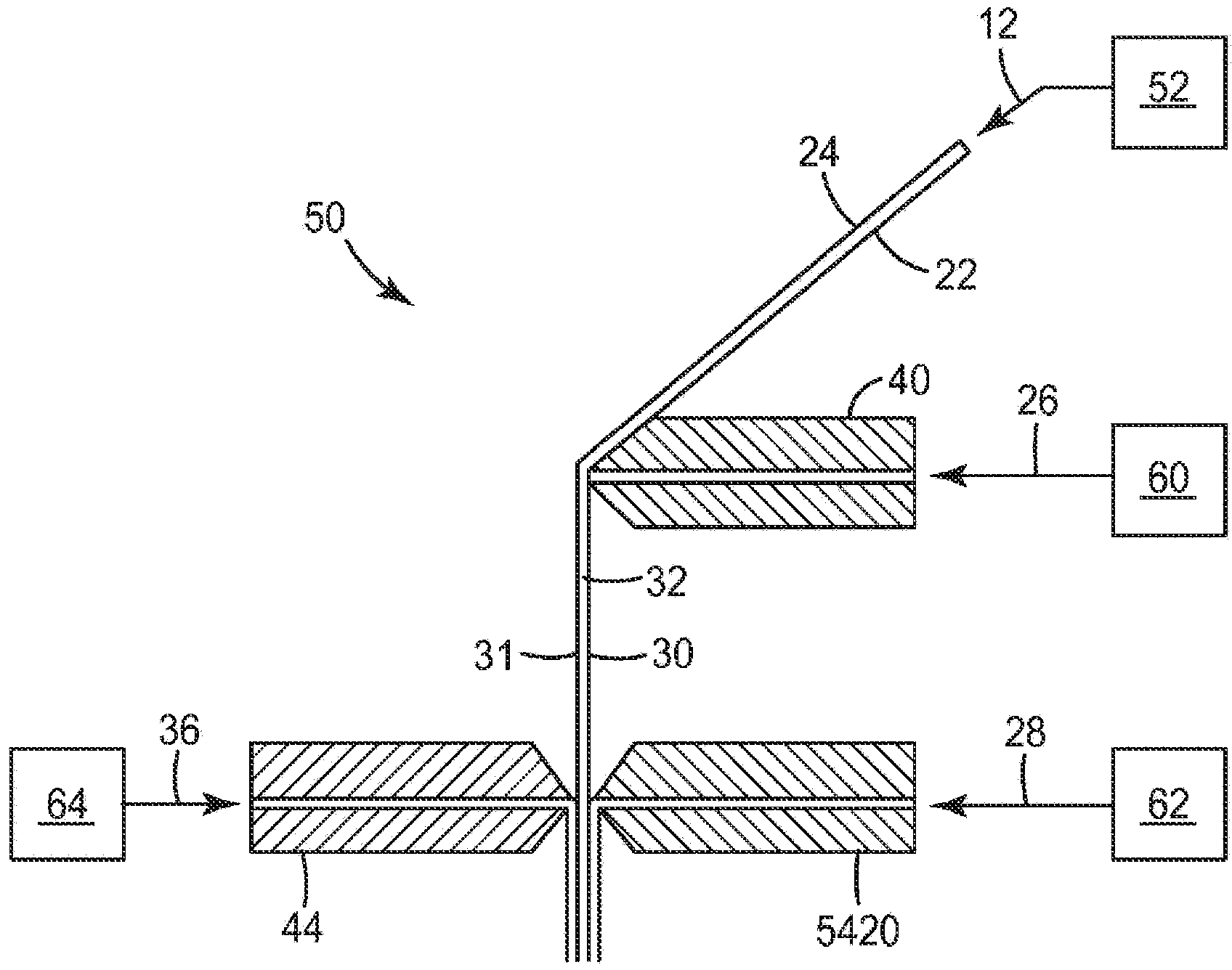

[0079] A BLA010 nylon 6,6 microfiltration (MF) membrane / support layer was placed on a flat glass plate with the large pore side facing the glass plate and all edges sealed with tape. First soak the MF membrane into the PIP / TEA aqueous solution for 2 min. The MF membrane was placed into the solution so that the backside of the plate was not soaked in the so...

example 2

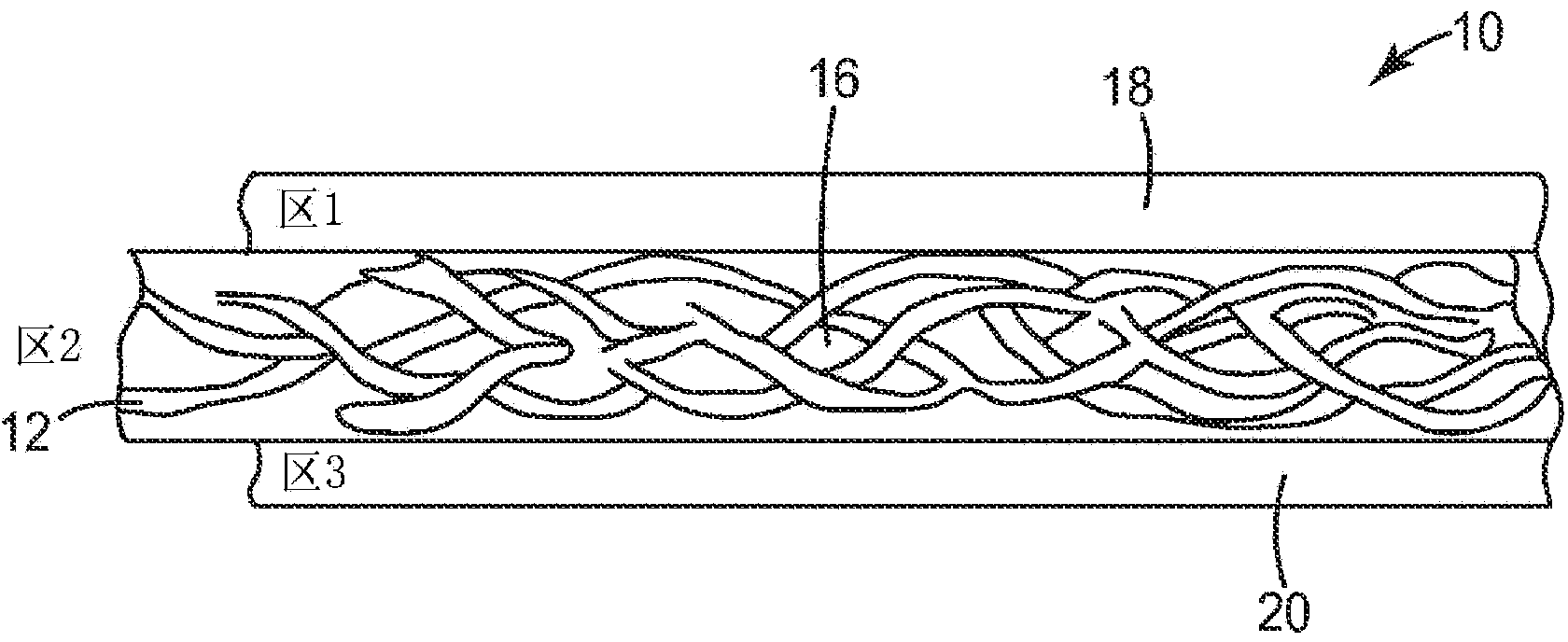

[0083] contrast

[0084] Commercially available asymmetric cellulose triacetate (HTI-CTA) forward osmosis (FO) membranes (Hydration Technology Innovations Inc., Albany, OR), TFC nanofiltration membrane NF270 and TFC seawater RO membrane SW30-XLE (Dow Water & Process Solutions Company, Midland, MI) for comparison. These membranes have three layers: a polyamide selective film layer, a microporous polysulfone (PSu) interlayer, and a high strength polyester support web.

example 3

[0086] experimental method

[0087] The surface morphology of the BLA010MF support and the TFC polyamide membrane was qualitatively evaluated by scanning electron microscopy (SEM) using a cold cathode field emission scanning electron microscope JSM-6335F (FEI, USA). Before imaging, the samples were kept in a desiccator overnight and sputter coated with a thin layer of platinum for better contrast and to avoid charge buildup.

[0088] The surface morphology of the BLA010MF support and the TFC polyamide membrane was qualitatively evaluated by scanning electron microscopy (SEM) using a cold cathode field emission scanning electron microscope JSM-6335F (FEI, USA). Before imaging, the samples were kept in a desiccator overnight and sputter coated with a thin layer of platinum for better contrast and to avoid charge buildup.

[0089] The cross-sectional structure of the BLA010 support and the selective layer of the TFC membrane were also imaged with SEM. These samples were prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com