Cow milk protein fatty acid modifier capable of inducing human breast cancer cell apoptosis, and preparation method thereof

A technology of human breast cancer cells and breast cancer cells, which is applied in the field of milk protein fatty acid modification and its preparation for inducing apoptosis of human breast cancer cells, can solve the problems of limited sources and difficult large-scale preparation, and promote intensive processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

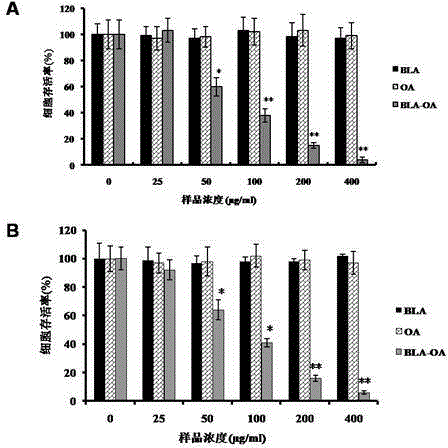

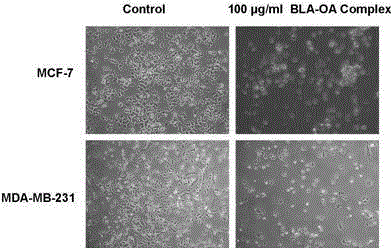

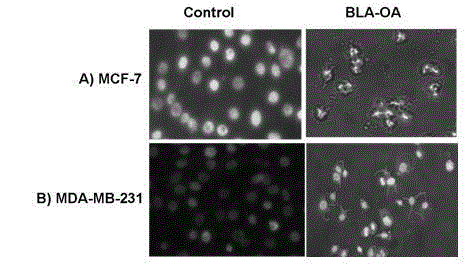

Examples

Embodiment 1

[0029] In the greenhouse, dissolve lactalbumin in 0.05mM EDTA, 10mM Tris-HCl, pH8.5 solution, overnight at 0~4℃ to remove Ca 2+ , concentrated by a protein ultrafiltration tube to obtain decalcified α-lactalbumin in an unfolded state; the final protein concentration is 100 μM; in a greenhouse, oleic acid is mixed with absolute ethanol, and ultrasonically fully dissolved to make a fatty acid stock solution; use Take the stock solution before adding 10mM Tris-HCl (pH8.5), the final concentration of ethanol in the solution is not more than 2% (V / V), the final concentration of oleic acid is 500μM; add the above fatty acid solution to DEAE-Sepharose fast flow anion column, using NaCl gradient elution to disperse fatty acids; add the above lactalbumin solution to an anion column pretreated with fatty acids; and use low ion concentration gradient (0.2M NaCl, 10mM Tris, pH8.5) Unbound fatty acids and milk proteins are then eluted with high-salt buffer (1M NaCl, 10mM Tris, pH8.5), and ...

Embodiment 2

[0031] In the greenhouse, dissolve lactalbumin in 1mmol / L EDTA, 20mM Tris-HCl, pH8.0 solution, overnight at 0~4℃ to remove Ca 2+, concentrated by protein ultrafiltration tubes to obtain decalcified α-lactalbumin in an unfolded state; the final protein concentration is 50 μM; in the greenhouse, oleic acid is mixed with absolute ethanol, and ultrasonically fully dissolved to make a fatty acid stock solution; use Take the stock solution before adding 20mM Tris-HCl (pH8.0), the final concentration of ethanol in the solution is not more than 2% (V / V), and the concentration of oleic acid is 800μM; add the above fatty acid solution to the DEAE-Sepharose fast flow anion column , using NaCl gradient elution to disperse the fatty acid; add the above lactalbumin solution to the anion column pretreated with fatty acid; and use low ion concentration gradient (0.2M NaCl, 10mM Tris, pH8.0) The combined fatty acid and milk protein are then eluted with high-salt buffer (1M NaCl, 10mM Tris, pH8...

Embodiment 3

[0033] In the greenhouse, dissolve lactalbumin in 0.08mM EDTA, 15mM Tris-HCl, pH8.2 solution, overnight at 0~4℃ to remove Ca 2+ , concentrated by a protein ultrafiltration tube to obtain decalcified α-lactalbumin in an unfolded state; the final protein concentration is 120 μM; in a greenhouse, linoleic acid is mixed into absolute ethanol, and ultrasonically fully dissolved to make a fatty acid stock solution; Take the stock solution before use and add 15mM Tris-HCl (pH8.2), the final concentration of ethanol in the solution is not more than 2% (V / V), the final concentration of linoleic acid is 1800μM; add the above fatty acid solution to DEAE-Sepharose fast flow anion column, using NaCl gradient elution to disperse fatty acids; add the above lactalbumin solution to an anion column pretreated with fatty acids; and use low ion concentration gradient (0.2M NaCl, 10mM Tris, pH8.5) to elute Unbound fatty acids and milk proteins were removed respectively, and then eluted with high-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com