A mechanical quick-change double-milling combination cutter for aluminum ingots

A mechanical and combined knife technology, which is applied in the direction of milling cutters, milling machine equipment, metal processing equipment, etc., can solve the problems of inconvenient installation and disassembly of blades, edge cracking, and poor tensile strength of tools, so as to achieve easier control of grinding operations, The effect of reducing milling resistance and saving replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

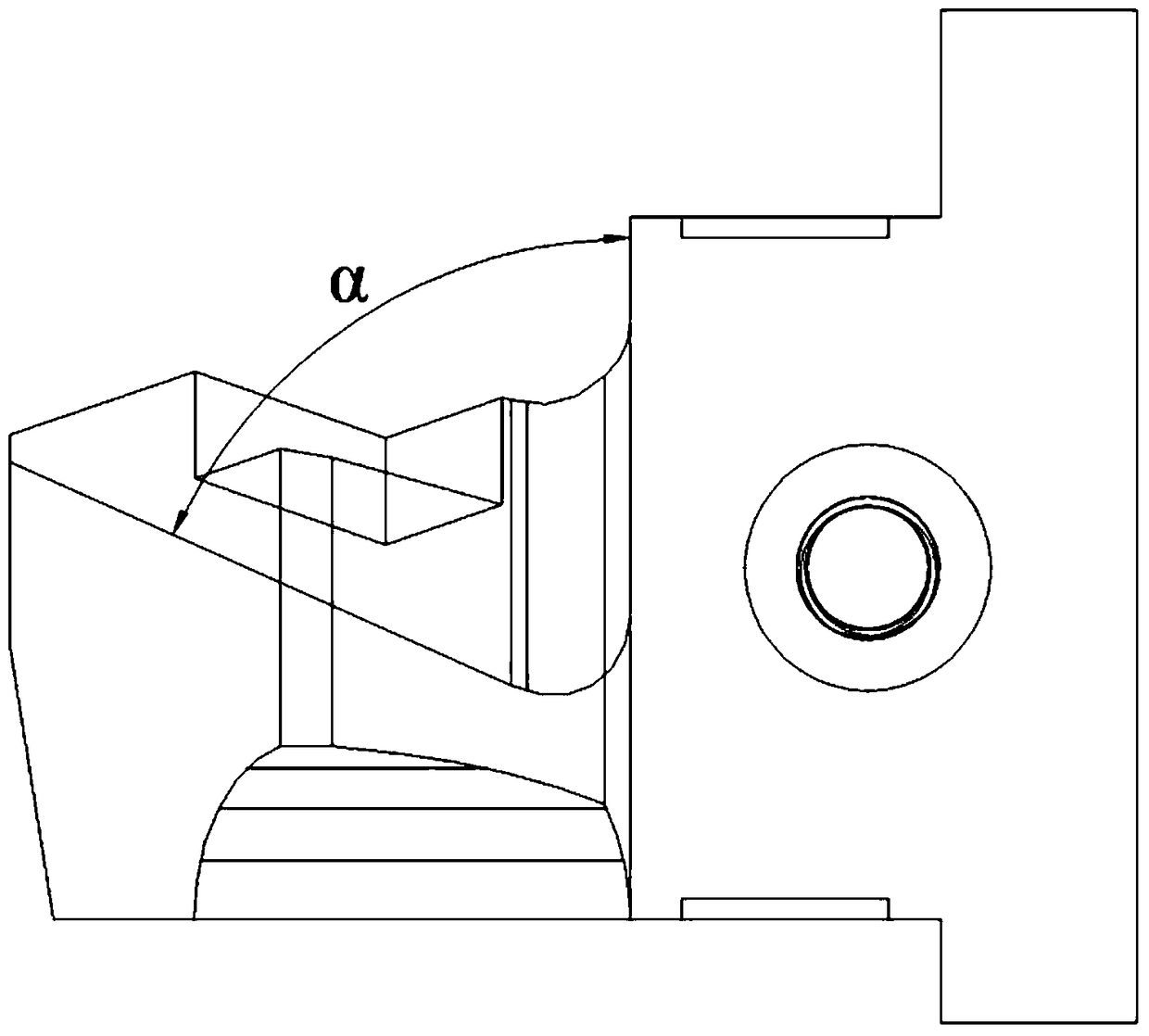

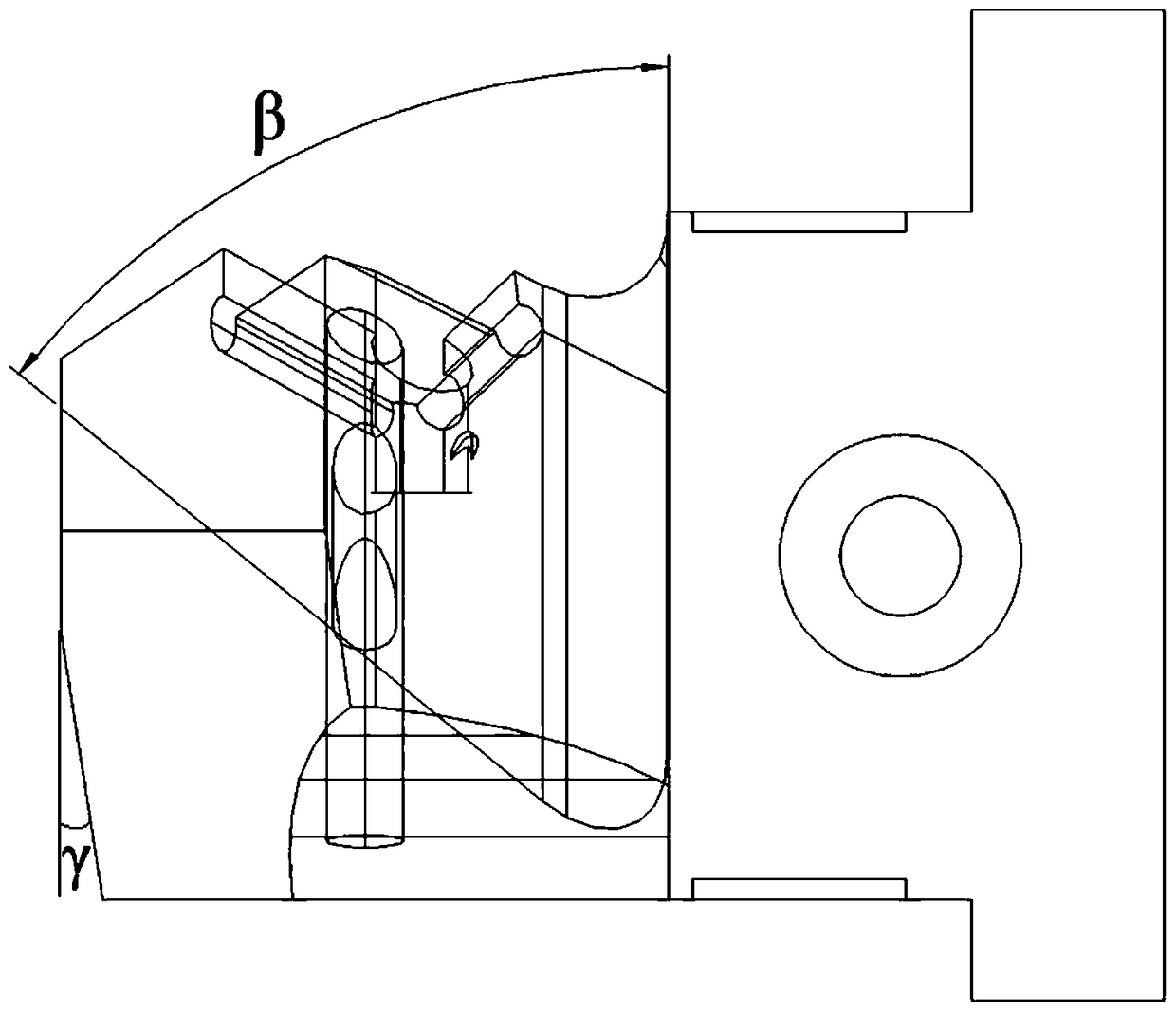

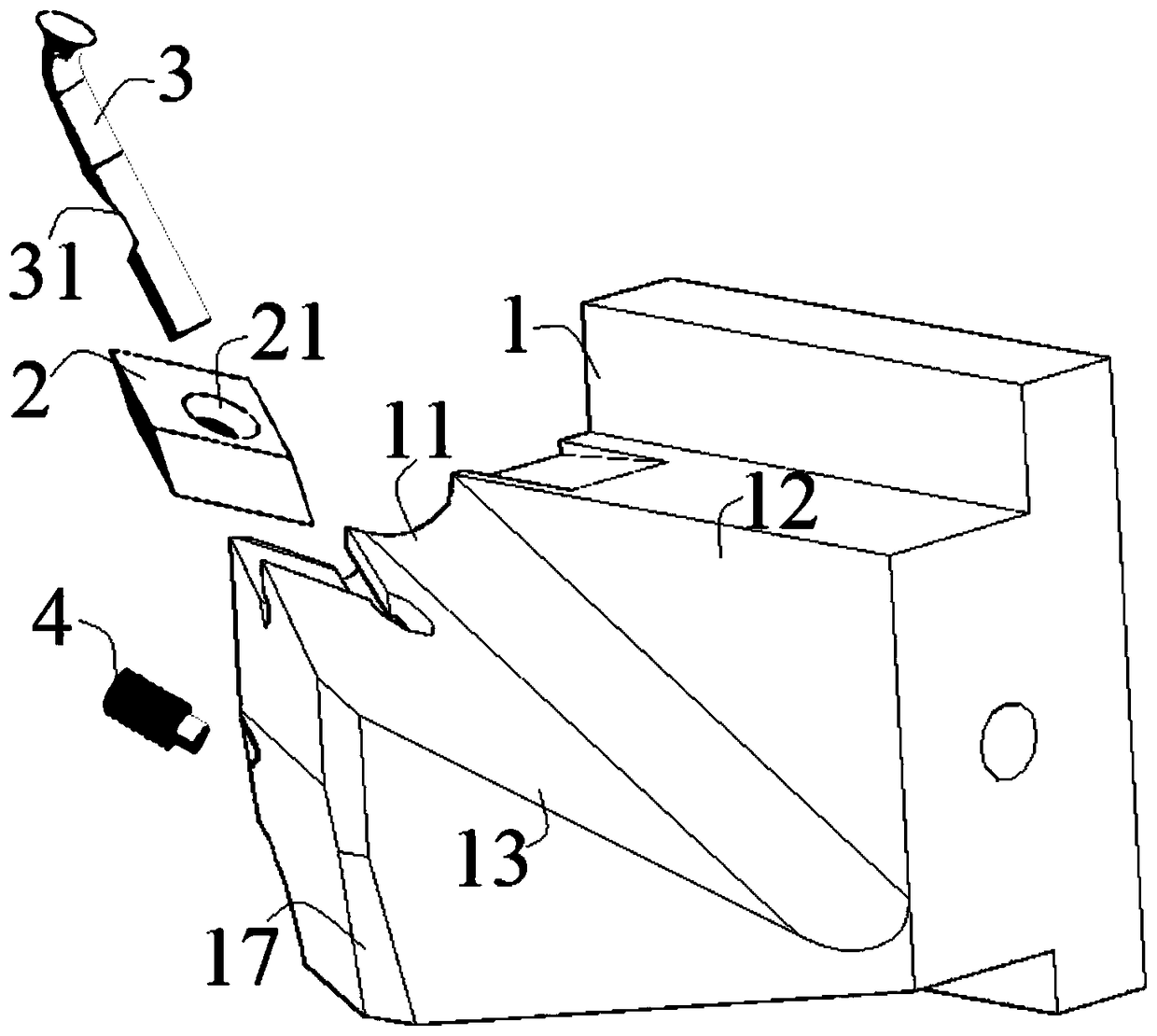

[0047] see image 3, a mechanical quick-change aluminum ingot double-milling combination cutter in this embodiment is mainly used for cutting metal aluminum ingots. The double-milling combination cutter includes 2 symmetrically arranged milling cutters. The shape and structure of the 2 milling cutters are similar. It mainly includes a cutter seat 1, a cutter head 2 and a quick change structure of the cutter head. see figure 2 In the present embodiment, the inclination angle β of the cutter head installation slope 13 of the cutter holder 1 relative to the cutter holder plane 12 is 51° (that is, the angle between the cutter head installation slope 13 and the cutter holder plane 12 is 51°). This inclination design is an innovation of the present embodiment. The inventor pointed out that at the beginning of the design of the tool seat 1 of the double milling combination cutter, it designed the inclination angle of the cutter head installation inclined surface 13 as follows accor...

Embodiment 2

[0072] A mechanical quick-change aluminum ingot double-milling combined cutter in this embodiment is basically the same as in Embodiment 1, except that the inclination β of the cutter head installation slope 13 relative to the tool seat plane 12 is designed to be 50° in this embodiment. °, the arc surface radius of the arc groove 11 is 15mm. In the tool seat processing technology of this embodiment: the components of the forged blank in step 1 are calculated by weight percentage: C: 0.44, Si: 0.37, Mn: 0.80, S: 0.035, P: 0.035, Cr: 1.1, Ni: 0.030 , Cu: 0.030, the rest is Fe. The annealing process of step 2 is as follows: first, the temperature is raised to 760°C, held for 6 hours, then cooled at a rate of 5°C / h, the temperature is lowered to below 600°C, and the furnace is air-cooled. After annealing, the hardness of the forged blank is 163HBS. The heat treatment process of step 4 is: heating to the quenching temperature of 860°C within 25 minutes, oil cooling; then tempering...

Embodiment 3

[0074] A mechanical quick-change aluminum ingot double-milling combination cutter in this embodiment is basically the same as in Embodiment 1, except that the inclination β of the cutter head installation slope 13 relative to the tool seat plane 12 is designed to be 55° in this embodiment. °, the arc surface radius of the arc groove 11 is 13mm. In the tool seat processing technology of this embodiment: the components of the forged blank in step 1 are calculated by weight percentage: C: 0.37, Si: 0.17, Mn: 0.50, S: 0.032, P: 0.034, Cr: 0.80, Ni: 0.028 , Cu: 0.030, the rest is Fe. The annealing process of step 2 is as follows: firstly, the temperature is raised to 740°C, held for 4 hours, then cooled at a rate of 7°C / h, the temperature is lowered to below 600°C, and the furnace is air-cooled. After annealing, the hardness of the forged blank is 160HBS. The heat treatment process of step 4 is: heating to the quenching temperature of 840°C within 25 minutes, oil cooling; then tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com