An induction reflow soldering device and a circuit board component welding method using the device

A technology for reflow soldering and circuit boards, applied in welding equipment, manufacturing tools, metal processing, etc., can solve problems such as unsuitable use of electrostatic sensitive devices, tombstone of small-volume SMT devices, poor thermal stress tolerance, etc. The effect of uneven heating of points, elimination of warping or delamination, and reduction of strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

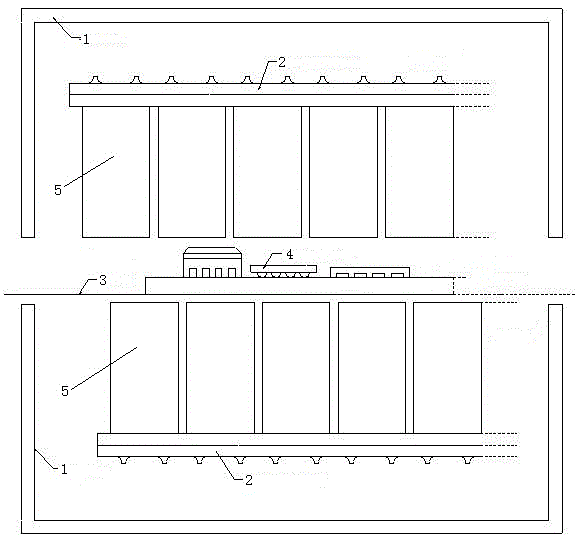

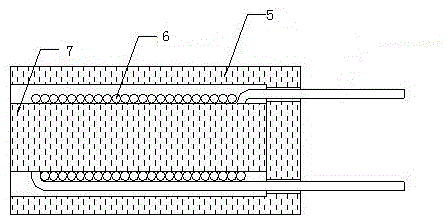

[0038] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

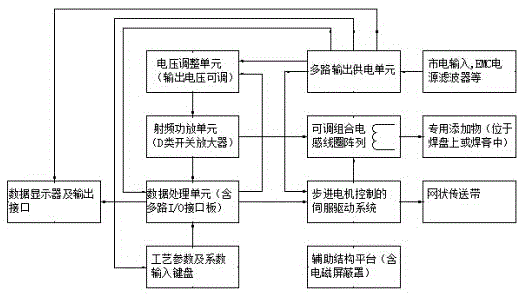

[0039] The invention provides a method for implementing induction reflow soldering, including a professional equipment induction reflow soldering system suitable for industrial applications and a miniaturized induction reflow soldering system that is convenient for personal use. All the SMD components on the board are induction welded continuously, quickly and efficiently at the same time, and in the case of expanding the size of the adjustable coil array, simultaneous welding of multiple printed boards is realized. The miniaturized system is used to complete the induction welding of a single SMT component on a single printed board. The block diagram of the induction welding system for professional equipment is shown in figure 1 As shown, the miniaturized system simply omits the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com