A design method for tailoring-induced spontaneous curling of graphene to form carbon nanocones

A carbon nanocone, design method technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high energy consumption, low yield, CNC structure defects, etc. Low, high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

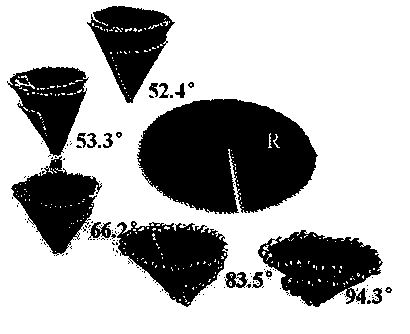

[0020] Carbon nanocones have attracted extensive attention from scholars at home and abroad because of their mechanical, electrical, optical, and thermal properties, making them have broad application prospects in micro-nano electronic devices. Aiming at the deficiencies in the existing preparation technology, the present invention proposes a simple and effective method for preparing carbon nano cones based on molecular simulation technology. In order to obtain the above-mentioned carbon nano cones, the specific implementation steps are as follows:

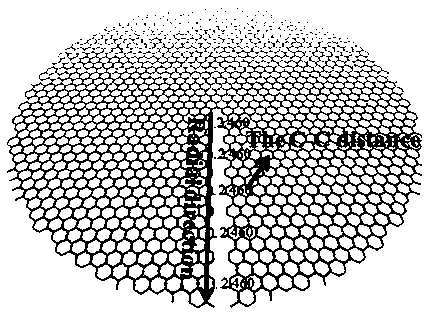

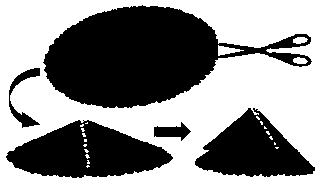

[0021] First, export the graphite unit cell from the MaterialsStudios simulation software structure database, then cut out the rectangular single-layer graphite unit cell along the (001) crystal direction of the unit cell, that is, the single-layer graphene unit cell, and then cut out the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com