Phase-transfer preparation method of graphene-based composite aerogel

A composite aerogel, graphene-based technology, applied in the field of nanoporous materials, can solve the problems of difficulty in obtaining nanomaterials with uniform latitude and size, difficult to achieve, and difficult to give full play to the characteristics and advantages of low-dimensional nanomaterials. For mass production, dimensional uniformity, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Further, a kind of phase transfer preparation method of graphene-based composite aerogel provided by the present invention comprises:

[0022] The graphene oxide solution that can exist stably for more than 1 day and the low-dimensional nanomaterial dispersion liquid that can exist stably for more than 1 day are evenly mixed, and a stable dispersion liquid of graphene and low-dimensional nanomaterials is obtained through a phase transfer process;

[0023] performing hydrothermal treatment on the stable dispersion of the graphene and the low-dimensional nanomaterial to obtain a graphene-based composite hydrogel;

[0024] And, drying the obtained graphene-based composite hydrogel to obtain the graphene-based composite aerogel.

[0025] Further, the phase transfer preparation method of the graphene-based composite aerogel includes: dispersing graphene oxide in an alkaline or neutral aqueous solution to form the graphene oxide dispersion.

[0026] Further, the phase transf...

Embodiment 1

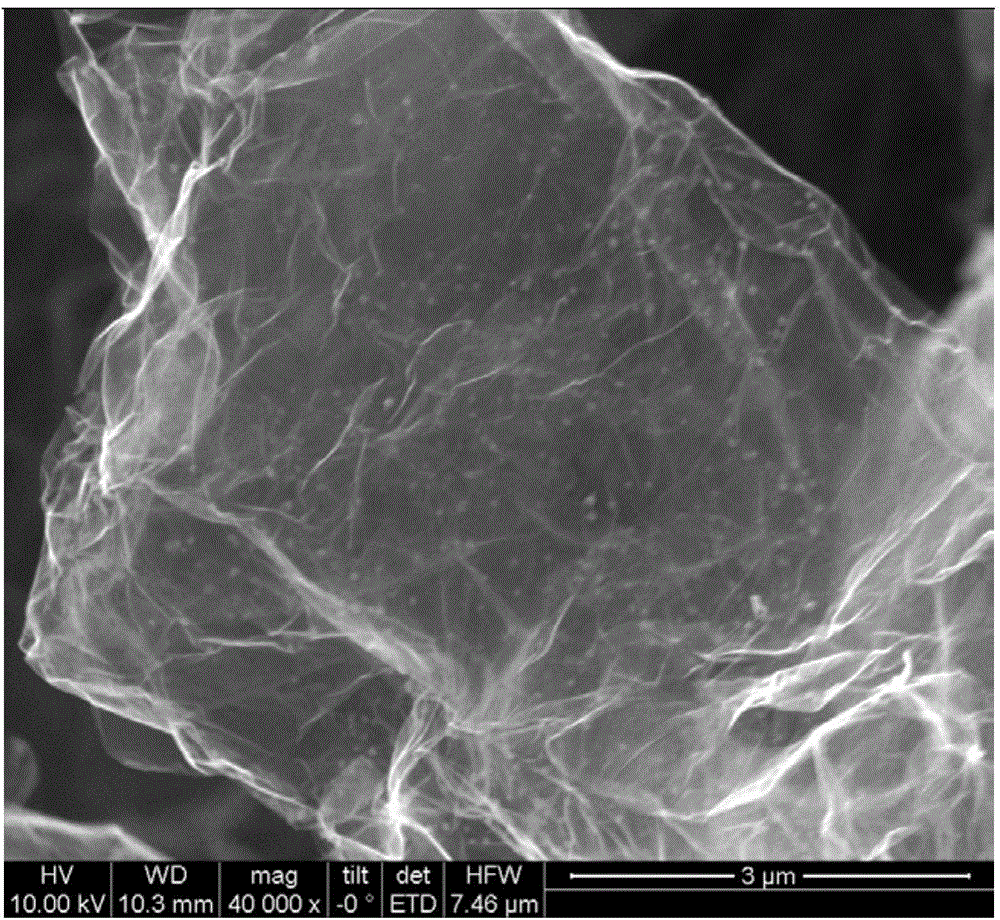

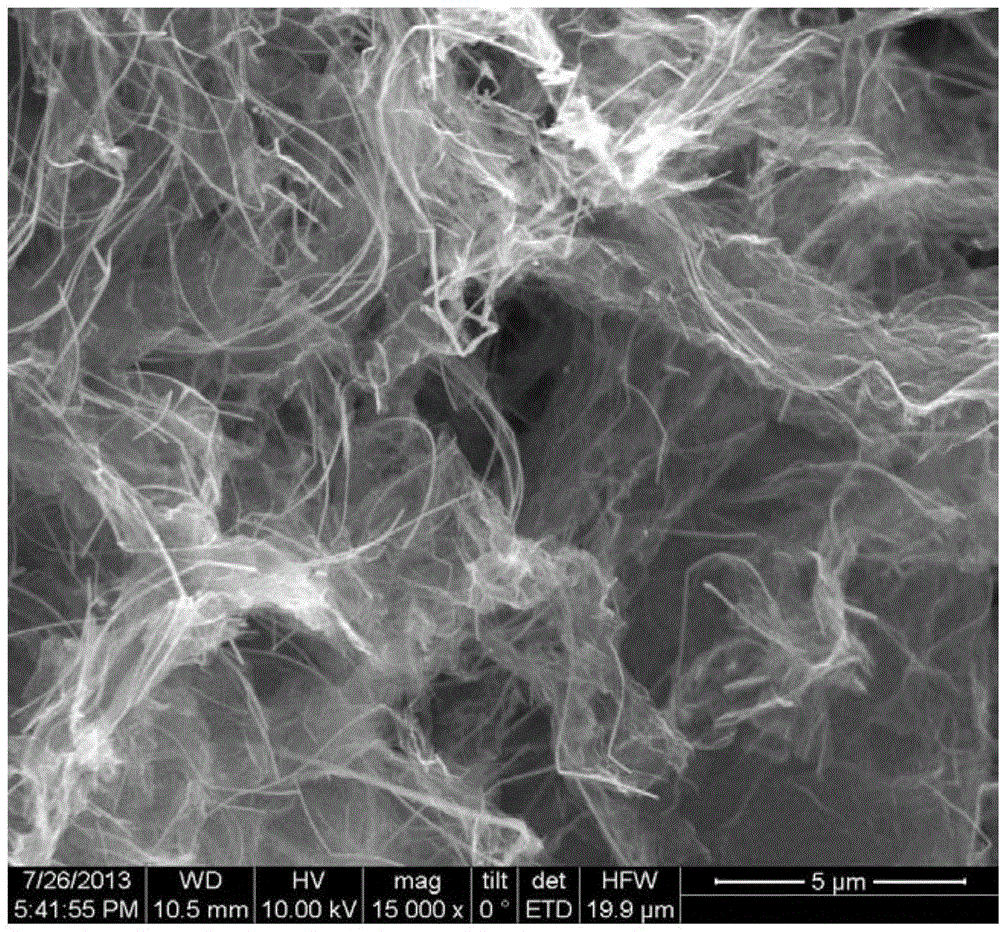

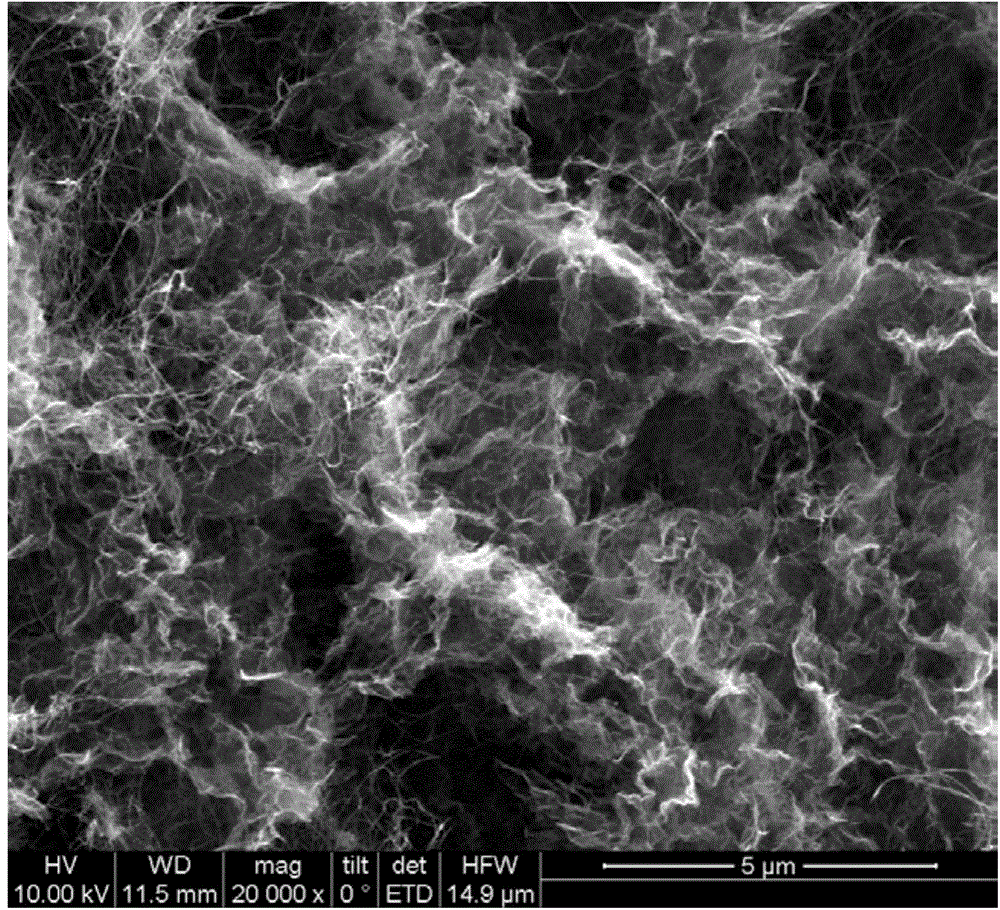

[0059] Example 1: The graphene oxide dispersion liquid is configured into a solution of 8 mg / mL, stirred for 20 minutes, and ultrasonicated for 30 minutes to obtain a uniformly dispersed graphene oxide solution, which is 10 mL of the solution; the polyvinylpyrrolidone solution of 4 mg / mL polypyrrole nanoparticles, wherein The concentration of polyvinylpyrrolidone is 5mg / mL, and 10mL of this solution is added to the above-mentioned graphene oxide solution, stirred for 30 minutes, and then ultrasonicated for 15 minutes to obtain a uniform mixed solution of graphene oxide-polypyrrole nanoparticles; The dispersion liquid of graphene oxide and polypyrrole nanoparticles mixed uniformly is phase transferred (centrifugal washing 10 times, the centrifugal speed is 10000 rpm), and the dispersion liquid of graphene oxide-polypyrrole nanoparticles after phase transfer is transferred. In a polytetrafluoroethylene reactor, hydrothermal treatment is performed to obtain a graphene-polypyrrol...

Embodiment 2

[0062] Example 2: The graphene oxide dispersion was configured into a solution of 8 mg / mL, stirred for 20 minutes, and ultrasonicated for 30 minutes to obtain a uniformly dispersed graphene oxide solution, which was 10 mL; the polyvinylpyrrolidone solution of 4 mg / mL silver nanowires, wherein the polyvinyl pyrrolidone solution was obtained. The concentration of vinylpyrrolidone is 5mg / mL, 10mL of this solution is added to the above graphene oxide solution, stirred for 30 minutes, and then ultrasonicated for 15 minutes to obtain a uniform mixture of graphene oxide-silver nanowires; The uniform dispersion of graphene oxide and silver nanowires is phase-transferred (centrifuged for 10 times, and the centrifugal speed is 10,000 rpm), and the graphene oxide-silver nanowire dispersion that has been phase-transferred is transferred to polytetrafluoroethylene. In an ethylene reactor, hydrothermal treatment is performed to obtain a graphene-silver nanowire composite hydrogel, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com