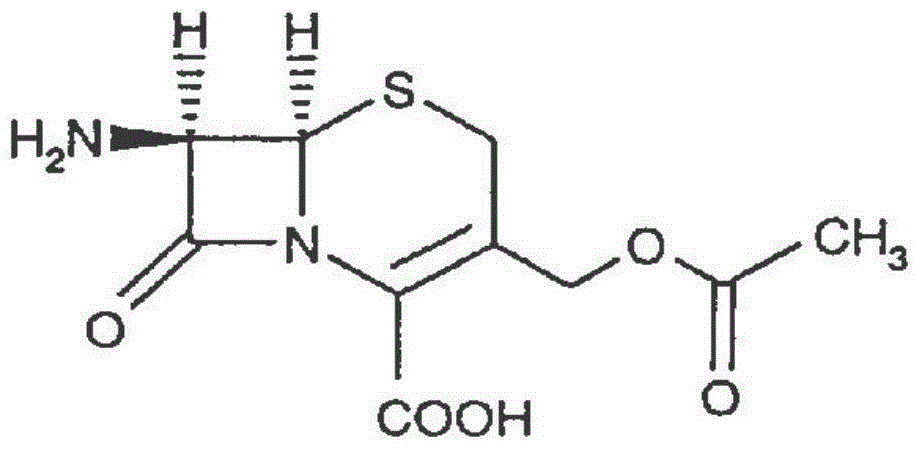

Method for recovering 7-aminocephalosporanic acid (7-ACA) from 7-ACA mother liquor

A technology of aminocephalosporanic acid and mother liquor, which is applied in the field of medicine, can solve the problems of cumbersome steps and high cost, and achieve the effects of simple process, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 10L of 7-ACA mother liquor (7-ACA content 1300μg / mL), adjust the pH to 7.0 with 3mol / L ammonia water, concentrate by nanofiltration 4 times; Science and Technology New Materials Technology Co., Ltd.) adsorption, the adsorption flow rate is 2BV / h (1BV refers to 1 times the resin column volume), the resin column capacity is 500mL, and a total of 12.82g is adsorbed. 3% sodium bicarbonate aqueous solution is used at 0.5BV / h speed analysis. Start collecting at 0.75BV and stop at 2.25BV. Adjust the pH of the collected analytical solution 0.75-2.25BV (total 750mL) with 10% hydrochloric acid to produce crystals, grow the crystals for 30 minutes, filter through a suction filter bottle, wash with 50ml×2 purified water, and then wash with 50ml×2 acetone . Suction filtration for 30 minutes, put into a vacuum drying oven and dry at 40° C. for 2 hours to obtain 8.02 g of 7-ACA product, which was detected by HPLC with a content of 99.10%.

Embodiment 2

[0024] Take 10 L of 7-ACA mother liquor (7-ACA content 1350 μg / mL), and adjust the pH to 7.0 with 3 mol / L ammonia water. Concentrate 4.5 times by nanofiltration, control the temperature at 5-10°C, and adsorb through LXT-032 resin (adsorption flow rate 2BV / h). The speed analysis of h starts to collect from 0.75BV and stops at 2.25BV. Adjust the pH of the collected analytical solution 0.75-2.25BV (total 750mL) with 10% hydrochloric acid until the crystals appear, grow the crystals for 30 minutes, continue to add 10% hydrochloric acid to pH=5.00, stop the dripping, and the temperature drops below 5°C. Cultivate the crystal for 30 minutes. After filtering through a suction filter flask, wash with 50ml×2 purified water, and then wash with 50ml×2 acetone. Suction filtration for 30 minutes, put into a vacuum drying oven and dry at 40° C. for 2 hours to obtain 8.12 g of 7-ACA product, which was detected by HPLC with a content of 99.00%.

Embodiment 3

[0026] Take 10 L of 7-ACA mother liquor (7-ACA content 1400 μg / mL), and adjust the pH to 7.0 with 3 mol / L ammonia water. Concentrate 5 times by nanofiltration, control the temperature at 5-10°C, and adsorb it through LXT-032 resin (adsorption flow rate 2BV / h). The speed analysis of h starts to collect from 0.75BV and stops at 2.25BV. Adjust the pH of the collected analytical solution 0.75-2.25BV (total 750mL) with 10% hydrochloric acid until the crystals appear, grow the crystals for 30 minutes, continue to add 10% hydrochloric acid to pH=5.00, stop the dripping, and the temperature drops below 5°C. Cultivate the crystal for 30 minutes. After filtering through a suction filter flask, wash with 50ml×2 purified water, and then wash with 50ml×2 acetone. Suction filtration for 30 minutes, put into a vacuum drying oven and dry at 40° C. for 2 hours to obtain 8.04 g of 7-ACA product, which was detected by HPLC with a content of 99.13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com