High-gloss aqueous modified polyurethane finish coat and preparation method thereof

A polyurethane topcoat and water-based polyurethane technology, applied in the field of paint making, can solve the problems of low gloss and poor anti-corrosion performance, and achieve the effect of high gloss, excellent anti-corrosion performance and enhanced anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

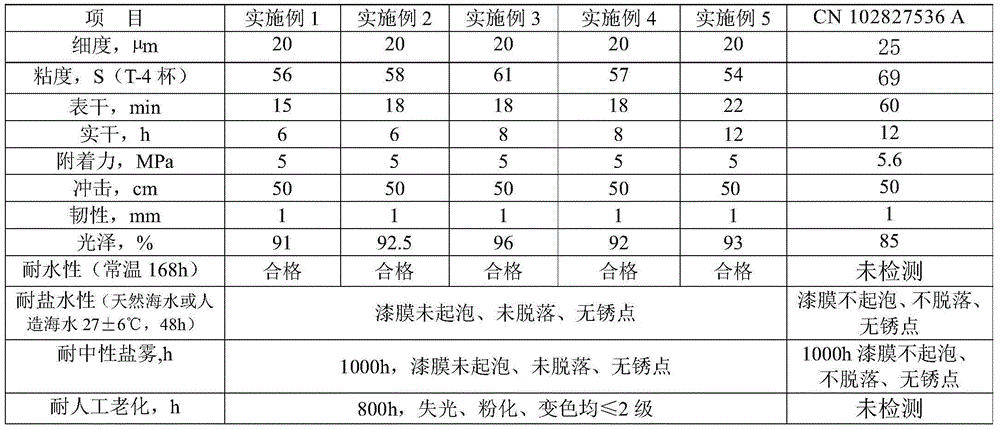

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0018] The raw materials used in the following examples are as follows:

[0019] Waterborne polyurethane dispersion (1201 Haishun Technology)

[0020] Epoxy modified acrylic emulsion (EA604 Beijing Jinhuili)

[0021] Medium chrome yellow (103-2A Chongqing Jiangnan Chemical Industry)

[0022] Nano barium sulfate (BS80 Beijing Gold Zebra)

[0023] Hydrated Magnesium Silicate (AD Haiyi Technology)

[0024] Dispersant (PX4585 BASF)

[0025] Foam inhibitor (A363 Haichuan Chemical)

[0026] Defoamer (NXZ Corning)

[0027] Leveling agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com