Fermented monascus cooking wine and production technology thereof

A production process and red yeast material technology, applied in the field of red yeast rice cooking wine and its production process, can solve the problems of no health care function and single function, and achieve the effects of simplifying the production process, improving production efficiency, and increasing the effect of removing mutton and fishy smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Rice soaking: sieve the glutinous rice to remove chaff, broken rice and other sundries, add water to the rice soaking tank, put the washed glutinous rice into the tank and soak for 2 days;

[0032] 2. Steam rice: Take out the soaked glutinous rice, rinse it and drain it, and steam the drained rice until the rice grains are fully cooked and there is no white heart inside;

[0033] 3. Drain the rice: Rinse the steamed glutinous rice with water to cool down;

[0034] 4. Blanking: Drain the excess water from the glutinous rice after pouring the rice and put it into the fermentation tank. Add water according to the ratio of glutinous rice: water = 1:1.5 (Kg / L), and add wheat koji and distiller's mother at the same time. The amount of wheat koji is used as the raw material 17% of the glutinous rice, 7% of the glutinous rice as the raw material, and 7% of the glutinous rice as the raw material. Finally, add red yeast rice powder and ultrasonic leaching solution of natural s...

Embodiment 2

[0050] 1. Rice soaking: sieve the glutinous rice to remove chaff, broken rice and other sundries, add water to the rice soaking tank, put the washed glutinous rice into the tank and soak for 3 days;

[0051] 2. Steam rice: Take out the soaked glutinous rice, rinse it and drain it, and steam the drained rice until the rice grains are fully cooked and there is no white heart inside;

[0052] 3. Drain the rice: Rinse the steamed glutinous rice with water to cool down;

[0053] 4. Blanking: Drain the excess water from the glutinous rice after pouring the rice and put it into the fermentation tank. Add water according to the ratio of glutinous rice: water = 1:1.3 (Kg / L), and add wheat koji and distiller's mother at the same time. The amount of wheat koji is used as the raw material 18% of the glutinous rice, 8% of the glutinous rice as the raw material, and 8% of the glutinous rice as the raw material. Finally, add red yeast rice powder and ultrasonic leaching liquid of natural spice...

Embodiment 3

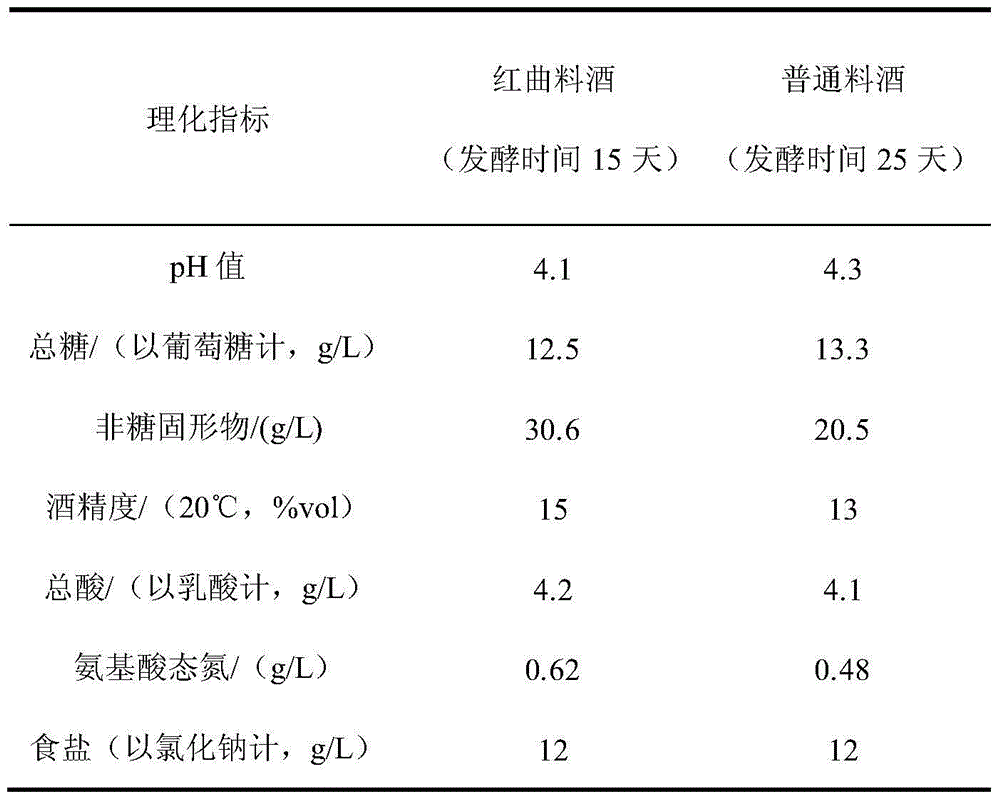

[0069] The red yeast rice wine that obtains by embodiment 1 and common cooking wine carry out physical and chemical index and functional component detection, and result is as follows:

[0070] (1) Physical and chemical indicators of red yeast rice wine and ordinary cooking wine

[0071] Table 1 Physicochemical indicators of red yeast rice wine and ordinary cooking wine

[0072]

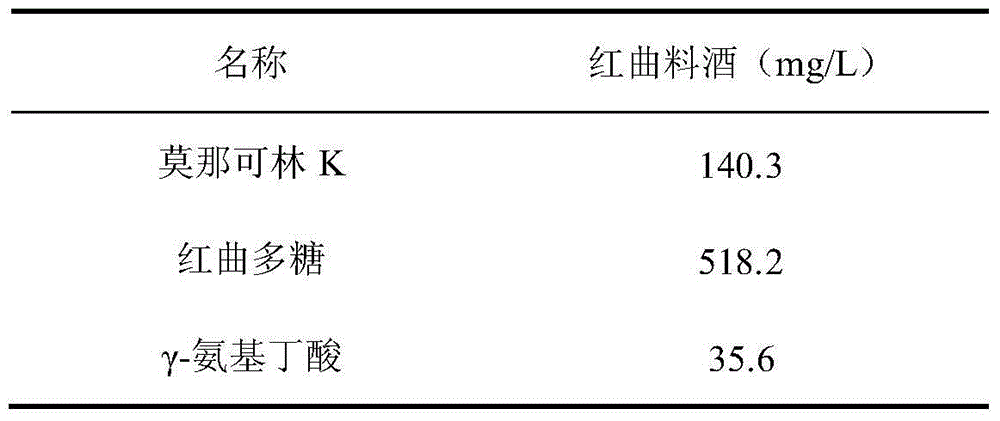

[0073] (2) Content of functional components in red yeast rice wine

[0074] Table 2 Contents of functional components in red yeast rice wine and red yeast rice wine

[0075]

[0076] As can be seen from the physical and chemical indicators of the product in the examples, the indicators of red yeast rice wine and common cooking wine are basically consistent, but the fermentation time is greatly shortened. In the red yeast rice wine prepared by this process, red yeast polysaccharide, monacolin K, The content of γ-aminobutyric acid can reach 518.2mg / L, 140.3mg / L, 35.56mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com