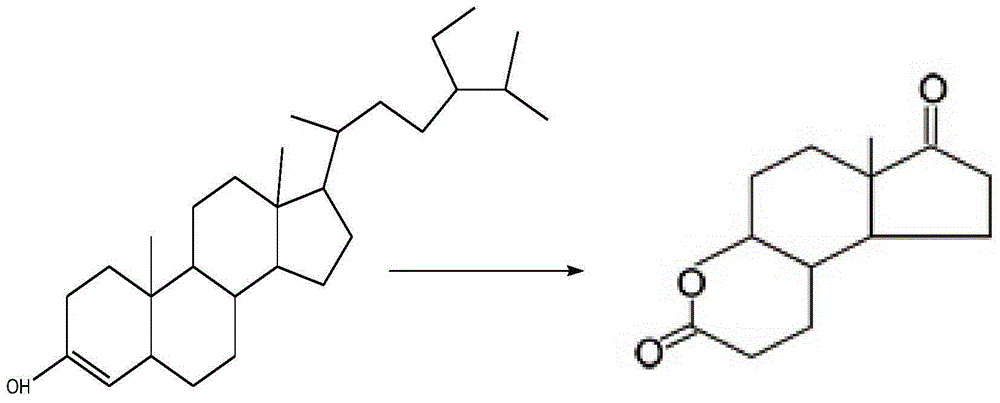

Method for producing A ring degradation products through plant sterol fermentation

A technology for phytosterols and degradants, which is applied in the field of fermenting phytosterols to produce A-ring degradants, can solve the problems of difficulty in product accumulation, great environmental impact, and difficulty in extraction, and achieves the effects of improving yield and inhibiting degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of Liquid Inoculum Containing Mycobacterium fortuitum

[0023] a1) Inclined seed culture

[0024] Slant seed medium is sterilized, inoculated with Mycobacterium fortuitum after cooling, and cultivated at 30°C for 3 to 5 days. The formula of described slant seed medium is as follows: yeast extract 12g / L, sodium nitrate 6.35g / L, potassium dihydrogen phosphate 1.0g / L, dipotassium hydrogen phosphate 2.0g / L, glucose 6g / L, potassium chloride 0.2 g / L, magnesium sulfate heptahydrate 0.8g / L, agar 20g / L, adjust the pH value to 7.1-7.2.

[0025] a2) Primary seed cultivation

[0026] The liquid seed medium was sterilized, cooled to room temperature, and the colony cultivated by the above-mentioned slope seeds was added to the primary liquid seed medium for cultivation. The cultivation temperature was 30° C., the cultivation rotation speed was 190 rpm, and the cultivation time was 48 hours. The formula of the primary liquid seed medium is as follows: corn steep liquor...

Embodiment 2

[0037] Preparation of Liquid Inoculum Containing Mycobacterium fortuitum

[0038] a1) Inclined seed culture

[0039] Slant seed medium was sterilized, inoculated with Mycobacterium fortuitum after cooling, and cultured at 32°C for 3 to 5 days. The formula of described slant seed medium is as follows: yeast extract 13g / L, sodium nitrate 6.4g / L, potassium dihydrogen phosphate 1.1g / L, dipotassium hydrogen phosphate 2.1g / L, glucose 6.5g / L, potassium chloride 0.15g / L, magnesium sulfate heptahydrate 0.9g / L, agar 22g / L, adjust the pH value to 7.1-7.2.

[0040] a2) Primary seed cultivation

[0041] The liquid seed medium was sterilized, cooled to room temperature, and the colony cultivated by the above-mentioned slope seeds was added to the primary liquid seed medium for cultivation. The cultivation temperature was 32° C., the cultivation speed was 200 rpm, and the cultivation time was 45 hours. The formula of the primary liquid seed medium is as follows: corn steep liquor 21g / L, s...

Embodiment 3

[0052] Preparation of Liquid Inoculum Containing Mycobacterium fortuitum

[0053] a1) Inclined seed culture

[0054] Slant seed medium was sterilized, inoculated with Mycobacterium fortuitum after cooling, and cultured at 28°C for 3 to 5 days. The formula of described slant seed medium is as follows: yeast extract 11g / L, sodium nitrate 6.3g / L, potassium dihydrogen phosphate 0.9g / L, dipotassium hydrogen phosphate 1.9g / L, glucose 5.5g / L, potassium chloride 0.1g / L, magnesium sulfate heptahydrate 0.7g / L, agar 18g / L, adjust the pH value to 7.1-7.2.

[0055] a2) Primary seed cultivation

[0056] The liquid seed medium was sterilized, cooled to room temperature, and the colony cultivated by the above-mentioned slope seeds was added to the primary liquid seed medium for cultivation. The cultivation temperature was 28° C., the cultivation rotation speed was 180 rpm, and the cultivation time was 50 hours. The formula of the primary liquid seed medium is as follows: corn steep liquor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com