Application of novel moderate temperature alpha-amylase

An amylase and a technology for processing starch, which are applied in the fields of starch and starch sugar product preparation technology, food additive technology and starch-containing product processing fields, can solve problems such as poor effect, and achieve the effects of prolonging shelf life, good application value and maintaining softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1 novel α-amylase

[0023] For details, see Examples 1-2 in the description of Chinese Invention Patent 201310043628.5.

Embodiment 2

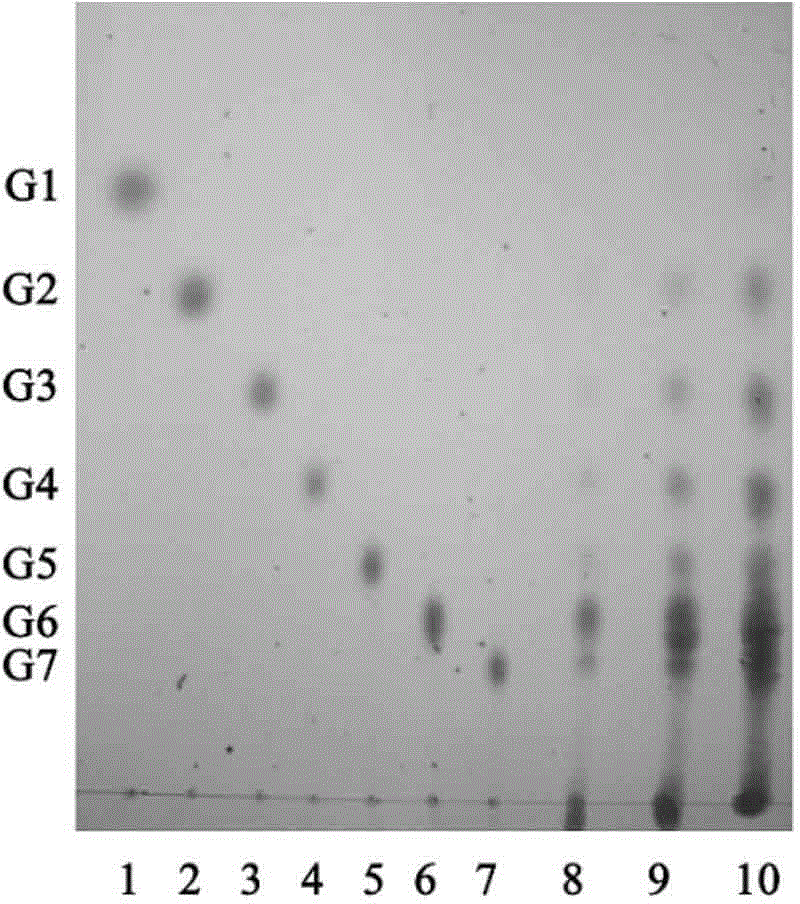

[0024] Embodiment 2. Novel α-amylase activity assay and product thin plate chromatography analysis

[0025] 1.0ml 0.5% soluble starch (50mM pH7.0 Tris-HCl buffer solution) (heated to 50°C first), add 1μl enzyme solution (after diluting the original solution 10 times), react at 50°C for 10min, add 2ml DNS to make up to After 3ml, boiled water bath for 5min, cooled, at OD 540 The absorbance value was measured under the following method, and the control group was heat-inactivated 1 μl enzyme solution (after the original solution was diluted 10 times), and the treatment was the same as above. The measured amylase activity was calculated according to the glucose standard curve, and the amount of enzyme required to produce 1 μmol of reducing sugar per minute at 50°C was defined as an activity unit.

[0026] Amylase AmyM handles starch 10 minutes, utilizes thin plate chromatography (TLC) to analyze its product component after 30 minutes and 1 hour, TLC condition is: developing agent...

Embodiment 3

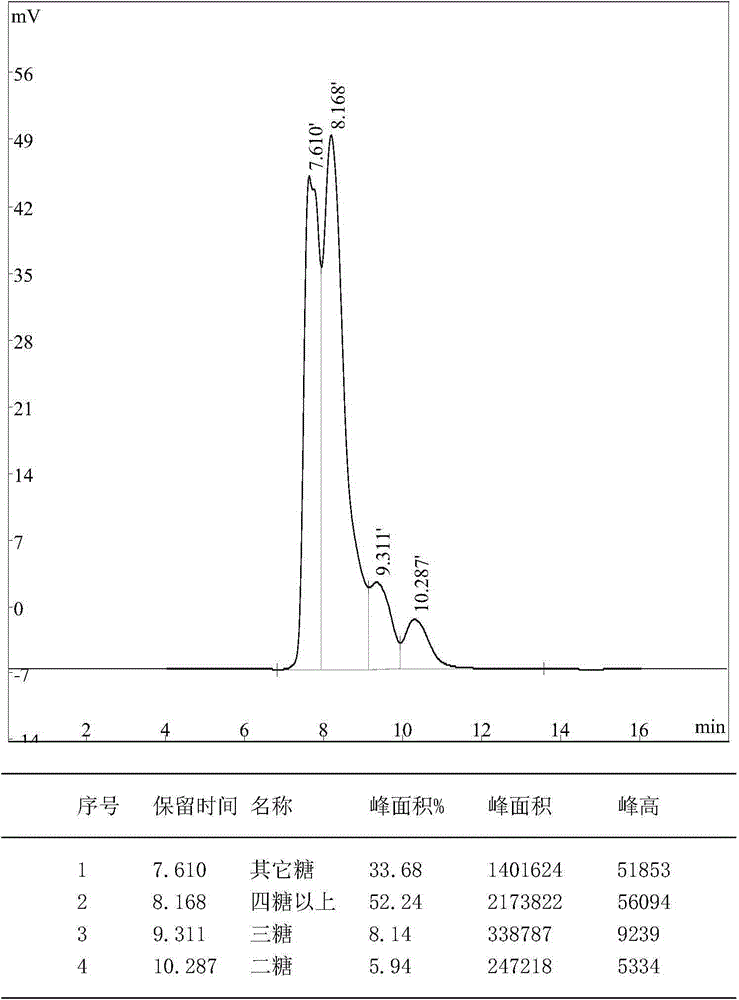

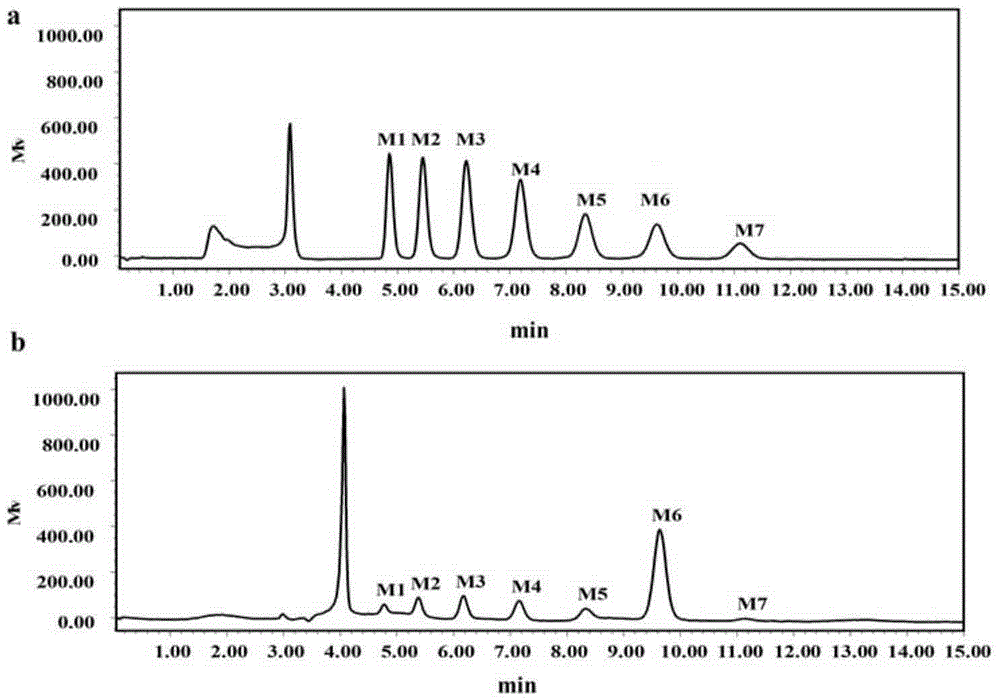

[0027] Example 3. Novel α‐amylase hydrolyzes starch to produce maltooligosaccharides based on maltohexaose

[0028] Make waxy corn starch (not limited to waxy corn) into 8% suspension, adjust the pH value to 6 with phosphate buffer solution, place it in a super constant temperature water bath at 99°C until it is completely gelatinized, and then completely gelatinize After the starch paste was cooled to 50°C, α-amylase AmyM was added, and the amount of α-amylase added was 5% of the dry starch base (equivalent to 100U per g dry starch base), and the products were collected for 3 and 12 hours, respectively. After 12 hours of enzymatic hydrolysis, the temperature was raised to 100°C for 20 minutes to inactivate the enzyme, and the collected product was analyzed using a KS803 column. The chromatographic column is Shodex KS‐803 (8mm×300mm), and the detector is a differential detector. The sample was prepared into a 2g / L solution, passed through a 0.45μm membrane, with ultrapure wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com