A creep aging forming method for 7075 aluminum alloy sheet

A technology of creep aging forming and aluminum alloy sheet, which is applied in the field of creep aging forming to achieve the effects of shortening the production cycle, improving corrosion resistance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

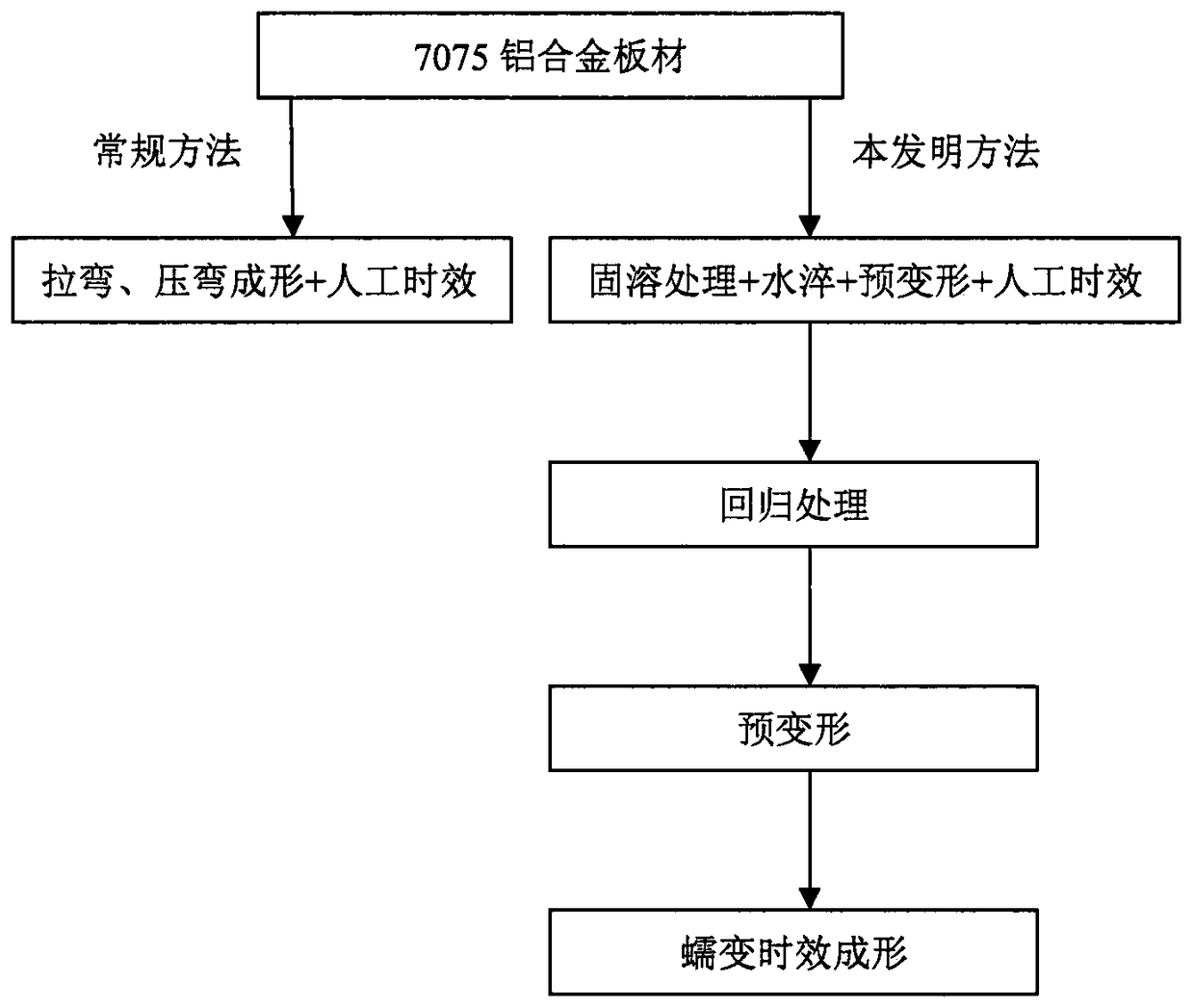

Method used

Image

Examples

Embodiment 1

[0021] A 3mm thick plate is solution treated at 470°C for 1 hour and then water quenched, followed by 3% pre-deformation and artificial aging at 120°C for 24 hours. The return temperature is 185°C, the heating rate is 10°C / min, and the water quenching is carried out immediately after returning to the heat preservation for 20 minutes. A 3% pre-deformation is performed. The creep aging temperature is 120°C, the applied stress is 260MPa, and the forming time is 24 hours.

Embodiment 2

[0023] B 3mm thick plate is solution treated at 470°C for 1 hour, then water quenched, followed by 3% pre-deformation and artificial aging at 120°C for 24 hours. The return temperature is 185°C, the heating rate is 10°C / min, and the water quenching is carried out immediately after returning to the heat preservation for 40 minutes. A 3% pre-deformation is performed. The creep aging temperature is 120°C, the applied stress is 260MPa, and the forming time is 24 hours.

Embodiment 3

[0025] C 3mm thick plate is solution treated at 470°C for 1 hour, then water quenched, followed by 3% pre-deformation and artificial aging at 120°C for 24 hours. The return temperature is 185°C, the heating rate is 10°C / mm, and the water quenching is carried out immediately after returning to the heat preservation for 60 minutes. A 3% pre-deformation is performed. The creep aging temperature is 120°C, the applied stress is 260MPa, and the forming time is 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com