Constructional partition plate and preparation method thereof

A partition wall panel and construction technology, applied to buildings, building components, building structures, etc., can solve the problems of increasing the load-bearing level of building design, difficulty in ensuring wall quality, inconvenient installation and construction, etc. The effect of high compressive strength and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

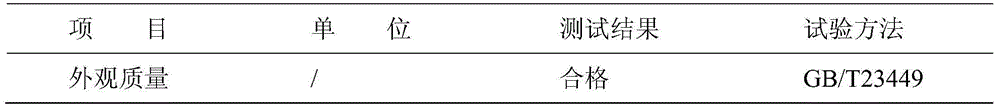

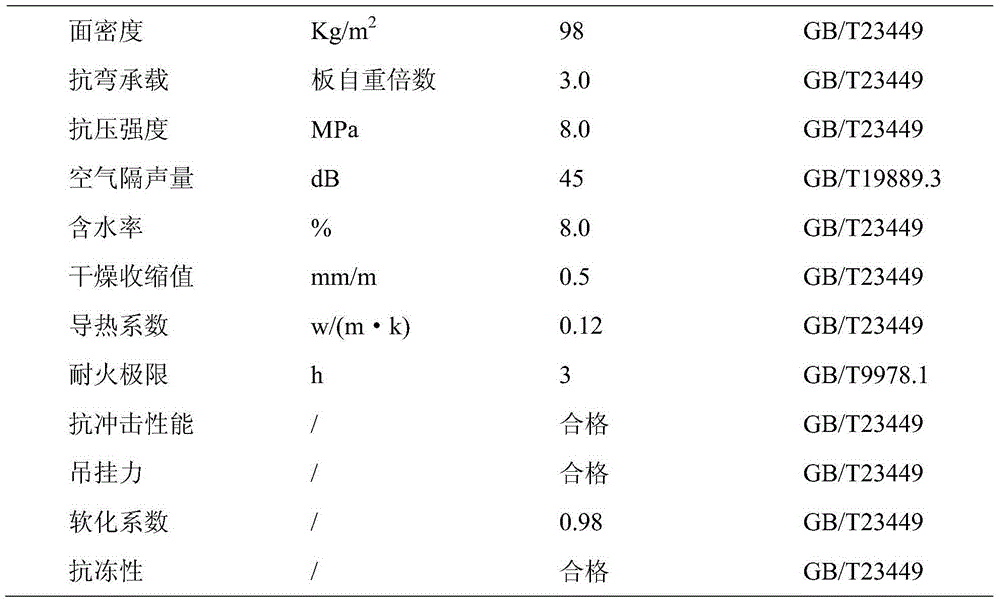

Embodiment 1

[0017] A partition wall panel for construction, the panel is a hollow panel, the panel width is 600mm, and there are 7 round holes arranged side by side in the cross section of the panel, and the diameter of the round hole is 58mm; 20mm; the partition board is made of the following components in parts by weight: 18 parts of cement, 30 parts of fly ash, 50 parts of construction waste powder, 1.5 parts of magnesium lignosulfonate, 2 parts of calcium sulfate, stearin Calcium acid 2 parts and emulsified oil 3 parts. Wherein, the construction waste slag powder is at least one of building bricks, concrete, and industrial slag, which is produced by primary crushing and ball milling and has a particle size below 120 mesh.

[0018] The specific preparation method of the above-mentioned partition board for construction is as follows: first foam the proportioned amount of cement, then add water to the foamed cement, proportioned amount of fly ash and construction waste powder and stir ev...

Embodiment 2

[0025] A partition wall panel for construction, the panel is a hollow panel with a panel width of 450 mm, five round holes with a hole diameter of 60 mm arranged in the cross section of the panel; the tongue and groove is a dovetail interlocking tenon and tenon groove, and the depth of the tenon and groove is 20 mm; The partition board is prepared from the following components in parts by weight: 15 parts of cement, 25 parts of fly ash, 45 parts of construction waste powder, 1 part of high-concentration naphthalenesulfonate formaldehyde condensate, 1 part of sodium sulfate, hard 2 parts of sodium hyaluronate and 4 parts of emulsified oil. Wherein, the construction waste slag powder is at least one of building bricks, concrete, and industrial slag, which is produced by primary crushing and ball milling and has a particle size below 120 mesh.

[0026] The preparation method and usage method of the partition board are the same as in Example 1, and the performance of the board is ...

Embodiment 3

[0028] A partition wall panel for building, the panel is a hollow panel, the panel width is 750mm, and there are 9 round holes arranged side by side in the cross section of the panel, and the diameter of the round hole is 35mm; The depth is 20mm; the partition wall board is made of the following components in parts by weight: 17 parts of cement, 28 parts of fly ash, 55 parts of construction waste powder, 2 parts of high-concentration naphthalenesulfonate formaldehyde condensate, sodium sulfate 1.5 parts, 3 parts of sodium stearate and 2 parts of emulsified oil. Wherein, the construction waste slag powder is at least one of building bricks, concrete, and industrial slag, which is produced by primary crushing and ball milling and has a particle size below 120 mesh.

[0029] The preparation method and usage method of the partition board are the same as in Example 1, and the performance of the board is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com