Car brake pad doped with aloe fiber powder and manufacturing method of brake pad

A technology of aloe vera fiber and brake pads, which is applied in the direction of chemical instruments and methods, friction linings, mechanical equipment, etc., can solve the problems that affect the uniformity of mixing, the strength and stability of brake pads, and cannot be effectively solved, so as to maintain stability, The effect of increasing the coefficient of friction and increasing the heat decay temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

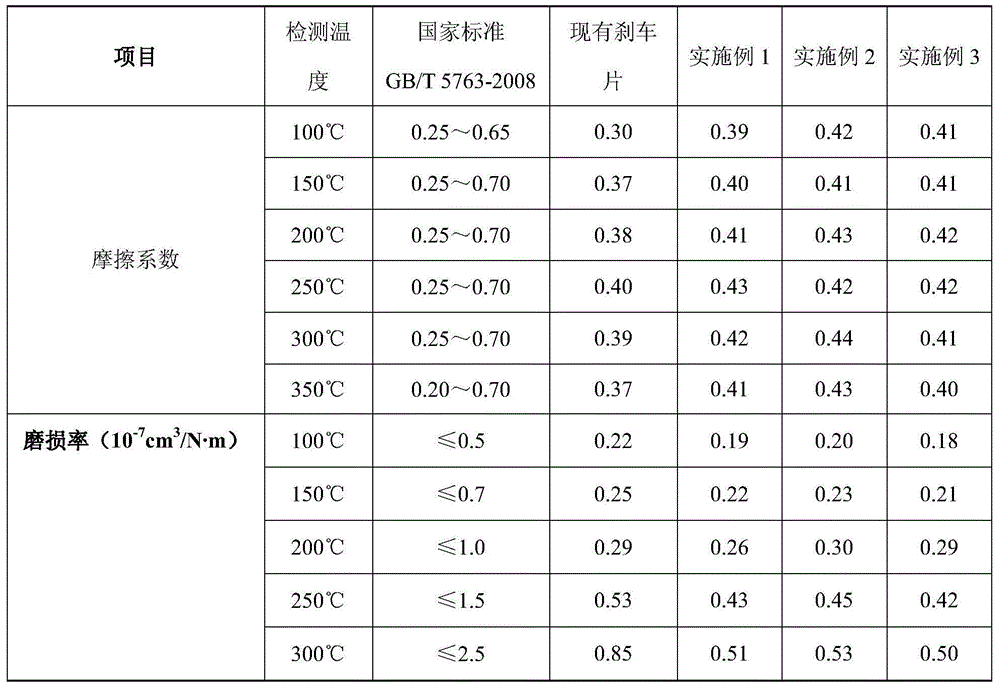

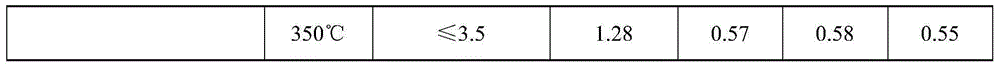

Examples

Embodiment 1

[0076] Example 1: At first select the raw material of following each component by weight part:

[0077] 10 parts of dewaxed aloe fiber powder;

[0078] Cashew nut shell oil modified phenolic resin 6 parts;

[0079] 6 parts of nitrile rubber powder;

[0080] 5 parts of graphite;

[0081] 5 parts of coke;

[0082] 2 parts of antimony trisulfide;

[0083] Aluminum oxide 1 part;

[0084] 20 parts of calcium carbonate;

[0085] 5 parts feldspar powder;

[0086] 2 parts fine iron ore powder;

[0087] Chromite powder 3 parts.

[0088] Put each raw material into a high-speed mixer with a stirring speed of 650r / min until the raw materials are evenly stirred; using the hot pressing process, pour the mixed raw materials into a mold, and press and solidify them on a hot press machine. The pressure setting is 30MPa, the hot-pressing temperature is 150°C, and the hot-pressing time is 10min; the hot-pressed brake pads are sent to a holding furnace for heat treatment, the furnace te...

Embodiment 2

[0089] Example 2: At first select the raw material of following each component by weight part:

[0090] 30 parts of dewaxed aloe fiber powder;

[0091] Cashew nut shell oil modified phenolic resin 12 parts;

[0092] 12 parts of nitrile rubber powder;

[0093] 10 parts of graphite;

[0094] 7 parts of coke;

[0095] 5 parts of antimony trisulfide;

[0096] 3 parts of aluminum oxide;

[0097] 40 parts of calcium carbonate;

[0098] 10 parts of feldspar powder;

[0099] 5 parts of fine iron ore powder;

[0100] Chromite powder 5 parts.

[0101] Put each raw material into a high-speed mixer with a stirring speed of 700r / min until the raw materials are evenly stirred; using the hot pressing process, pour the mixed raw materials into a mold, and heat and solidify them on a hot press machine. The pressure setting is 50MPa, the hot-pressing temperature is 170°C, and the hot-pressing time is 15min; the hot-pressed brake pads are sent to a holding furnace for heat treatment, ...

Embodiment 3

[0102] Example 3: At first select the raw material of following each component by weight part:

[0103]20 parts of dewaxed aloe fiber powder;

[0104] Cashew nut shell oil modified phenolic resin 9 parts;

[0105] 9 parts of nitrile rubber powder;

[0106] 8 parts graphite;

[0107] 6 parts of coke;

[0108] 3 parts of antimony trisulfide;

[0109] Aluminum oxide 2 parts;

[0110] 30 parts of calcium carbonate;

[0111] 8 parts feldspar powder;

[0112] 4 parts fine iron ore powder;

[0113] 4 parts of chromite powder.

[0114] Put each raw material into a high-speed mixer with a stirring speed of 680r / min until the raw materials are evenly stirred; using the hot pressing process, pour the mixed raw materials into a mold, and heat and solidify them on the hot press. The pressure setting is 40MPa, the hot-pressing temperature is 160°C, and the hot-pressing time is 12min; the hot-pressed brake pads are sent to a holding furnace for heat treatment, the furnace temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com