Flue gas water recycling system

A water recovery and flue gas technology, applied in water shower coolers, combustion methods, indirect carbon dioxide emission reduction, etc., can solve the problems of large volume and cost of flue gas coolers, large heat exchange temperature difference, etc., and achieve efficient and low-cost recovery , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments describe the flue gas water recovery system involved in the present invention in detail in conjunction with the accompanying drawings and embodiments.

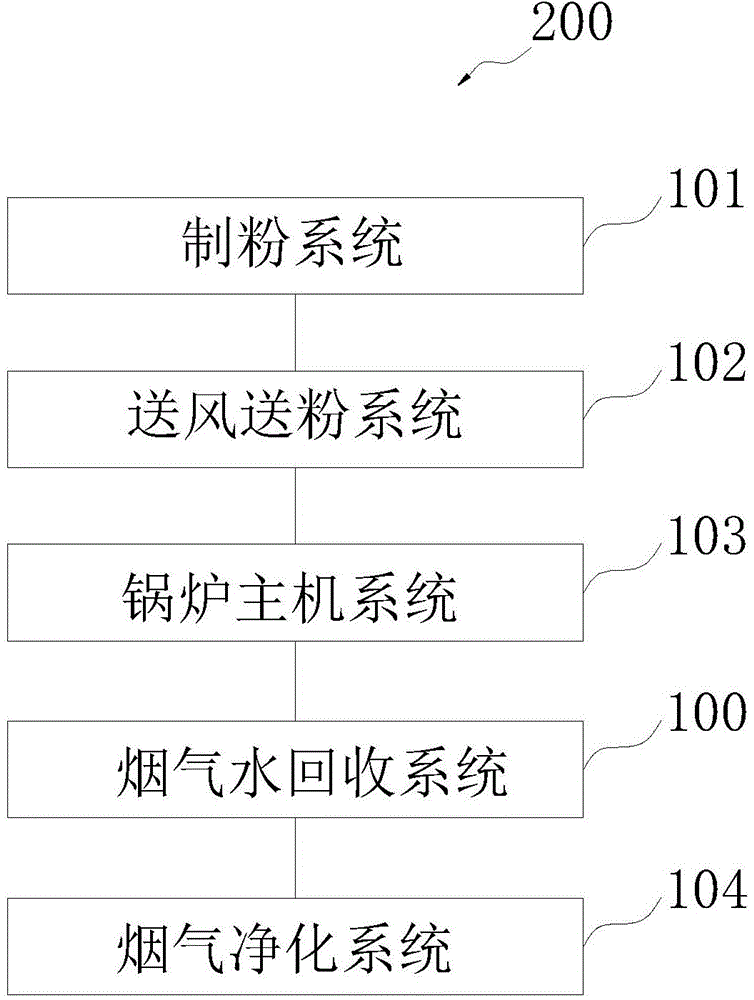

[0020] figure 1 It is a structural block diagram of the boiler system in the embodiment of the present invention.

[0021] Such as figure 1 As shown, the boiler system 200 is used to burn coal to generate a large amount of flue gas, which contains moisture, especially the flue gas generated by burning high-moisture coal as fuel has a relatively high moisture content.

[0022] The boiler system 200 includes: a flue gas water recovery system 100 , a powder making system 101 , an air and powder feeding system 102 , a boiler host system 103 and a flue gas purification system 104 . The pulverizing system 101 is used to provide pulverized coal, the air pulverized powder supply sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com