Outline dicing and sheet picking method for ultrathin quartz substrate thin film circuit

A thin-film circuit and circuit graphics technology, which is applied to circuits, electrical components, grinding machines, etc., can solve problems such as direct and effective pick-up of difficult workpieces, scratches on the surface of the circuit, and collapse of the shape of the thin-film circuit, so as to achieve a good circuit appearance , easy to wrap, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

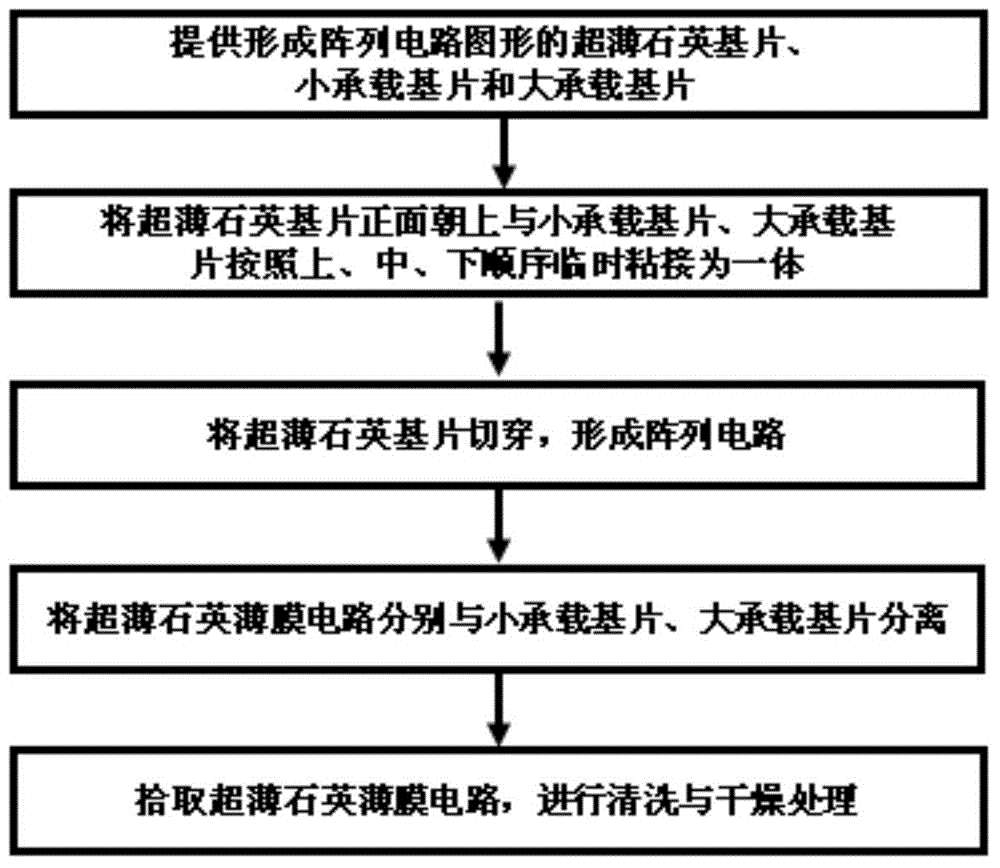

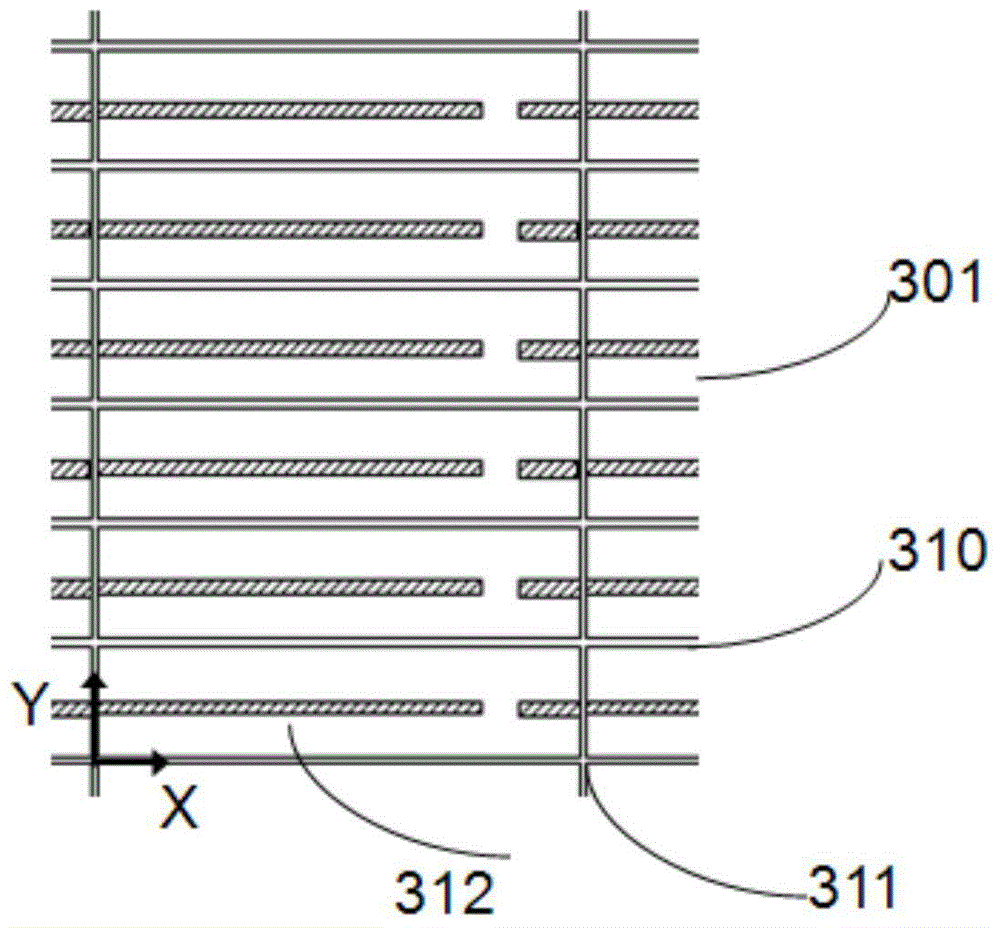

[0049] Scribe and cut a rectangular thin film circuit in the form of a 3×22 array on a square ultra-thin quartz substrate with a thickness of 50 μm and a plane size of 20mm×20mm. The slits in the X direction and the Y direction are both 80 μm in size. The surface and the back are metal-free film surfaces. The plane size of the film circuit pattern is 4.8mm×0.3mm, and the aspect ratio is 16:1.

[0050] Step 1, providing an ultra-thin quartz substrate, a small carrying substrate and a large carrying substrate for forming an array circuit pattern.

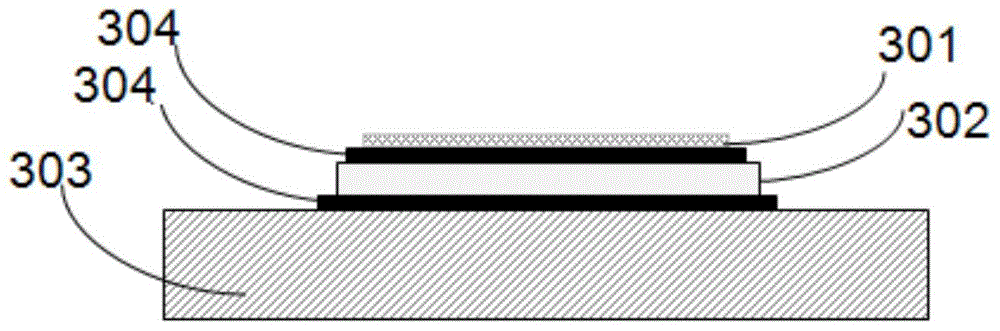

[0051] First, provide a 50 μm thick square ultra-thin quartz substrate 301 with a plane size of 20mm×20mm, the front side is a surface for forming an array circuit pattern, and the back side is a metal-free film surface; then prepare a 0.5mm thick, plane size 25.4mm×25.4 mm square quartz glass is used as the small carrier substrate 302; and a square quartz glass with a thickness of 1.5 mm and a plane size of 76.2 mm×76.2 mm is prepare...

Embodiment 2

[0061]Scribe a 2×21 thin-film circuit in an array form on a square ultra-thin quartz substrate with a thickness of 30 μm and a plane size of 20mm×20mm. The slits in the X direction and the Y direction are both 50 μm in size. The back side is a full-board thin-film metallization ground plane, the plane size of the thin-film circuit pattern is 7.8mm×0.2mm, and the aspect ratio is 39:1.

[0062] Step 1, providing an ultra-thin quartz substrate, a small carrying substrate and a large carrying substrate for forming an array circuit pattern.

[0063] First, provide a 30 μm thick square ultra-thin quartz substrate 301 with a plane size of 20mm×20mm. A square quartz glass of mm×25.4 mm is used as the small carrier substrate 302 ; and a square quartz glass with a thickness of 1 mm and a planar size of 76.2 mm×76.2 mm is prepared as the large carrier substrate 303 .

[0064] Step 2, bonding the ultra-thin quartz substrate with the front side up to the small carrier substrate and the la...

Embodiment 3

[0073] Scribe and cut a double-sided film circuit in the form of a 5×20 array on a square ultra-thin quartz substrate with a thickness of 50 μm and a plane size of 20 mm×20 mm. , the back is an array circuit graphic surface that is symmetrical to the front circuit graphic, the plane size of the thin film circuit graphic is 2.4mm×0.3mm, and the aspect ratio is 8:1.

[0074] Step 1, providing an ultra-thin quartz substrate, a small carrying substrate and a large carrying substrate for forming an array circuit pattern.

[0075] First provide a square ultra-thin quartz substrate 301 with a thickness of 50 μm, with a plane size of 20mm×20mm, the front is a surface for forming an array circuit pattern, and the back is a surface for forming an array circuit pattern symmetrical to the front circuit pattern; then prepare a 0.5mm thick, A square quartz glass with a planar size of 25.4mm×25.4mm is used as the small carrier substrate 302;

[0076] Step 2, bonding the ultra-thin quartz su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com