Process station for a machine as well as control device and control method

A technology of a control device and a control method, applied in the field of processing stations, can solve the problems of increased processing costs, time-consuming, and high machine costs, and achieve the effects of reducing processing costs and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

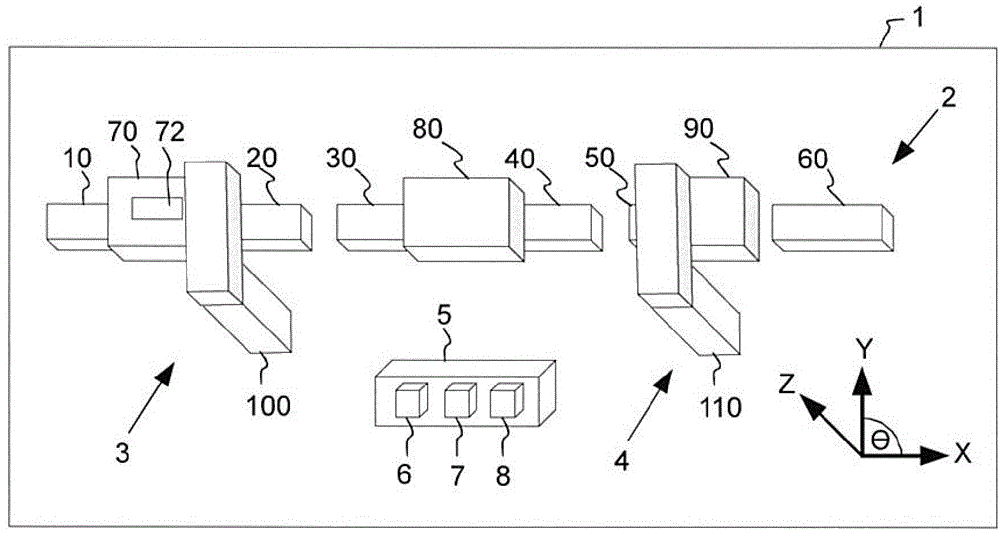

[0036] figure 1 Shown is a machine 1 for producing items such as semiconductor components or the like on a substrate such as a wafer. The machine 1 comprises a conveyor system 2 connecting a first processing station 3 and a second processing station 4 . The machine 1 also comprises a control device 5 having a first control unit 6 , a second control unit 7 and a third control unit 8 . Machine 1 may be a production line.

[0037] figure 1 The conveying system 2 in includes the first driving device 10, the second driving device 20, the third driving device 30, the fourth driving device 40, the fifth driving device 50, the sixth driving device 60, the first carrier 70, the second carrier 80 and a third carrier 90 , the first carrier 70 carries a load 72 (such as objects to be produced by the machine 1 , etc.). The first to third carriers 70 , 80 , 90 can be moved in the transport system 2 by magnetic force generated by the first to sixth drive devices 10 , 20 , 30 , 40 , 50 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com