High wear resistance high hardness polyformaldehyde composition and preparation method thereof

A polyoxymethylene composition and polyoxymethylene technology are applied in the field of composite materials, which can solve the problems of complex modification process of silicon carbide, lack of data support, poor modification effect, etc., and achieve high hardness, improved dispersibility, and improved hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

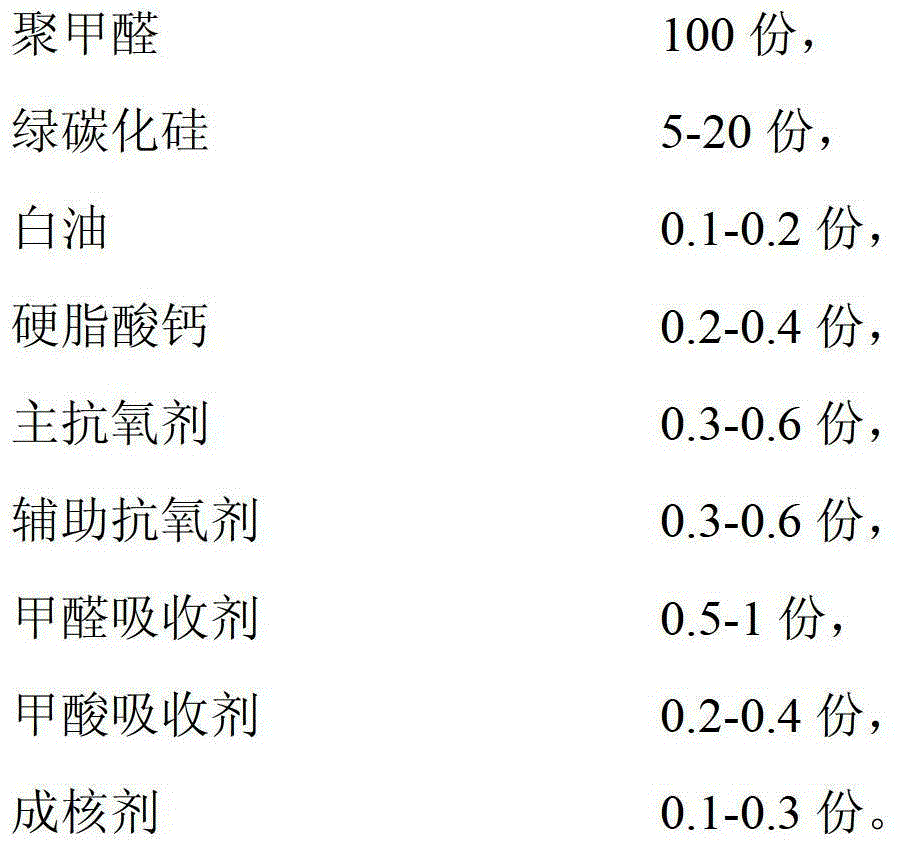

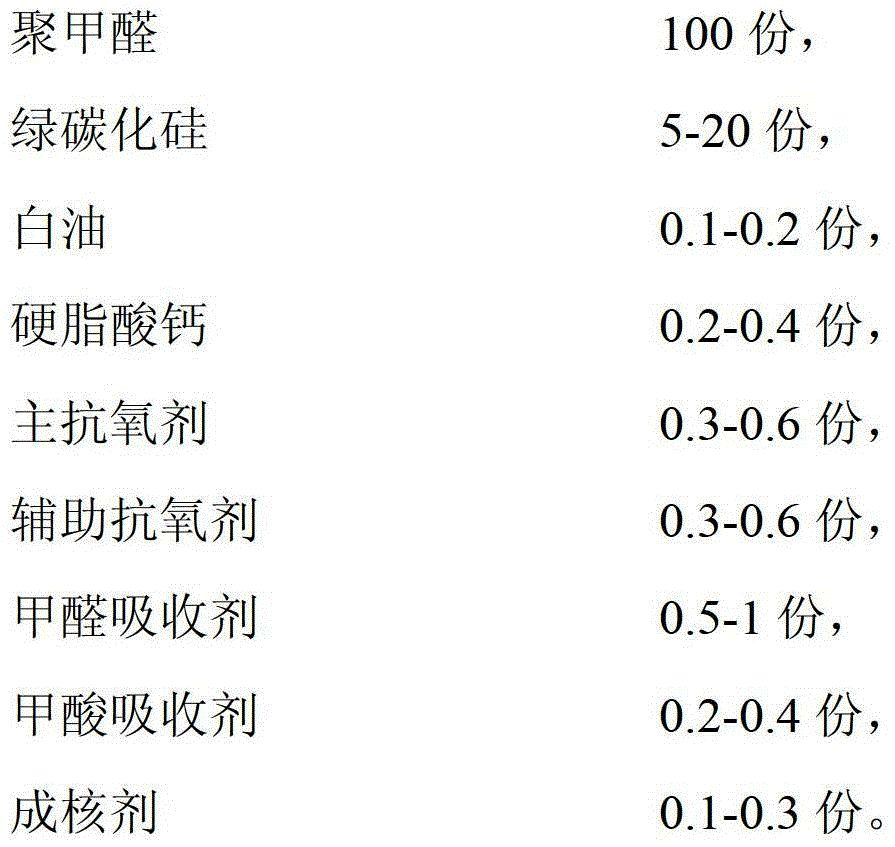

[0047] Take the following materials by weight:

[0048] 100 parts of polyoxymethylene, 10 parts of treated green silicon carbide, 0.1 parts of white oil, 0.2 parts of calcium stearate, antioxidant 1010: 0.3 parts, antioxidant 168: 0.6 parts, 1 part of melamine formaldehyde condensate, oxidation 0.2 parts of magnesium, 0.3 parts of diatomaceous earth; dry polyoxymethylene at 80°C for 3 hours, then add the above-mentioned other materials into a high-speed mixer and mix;

[0049] Use a vented co-rotating twin-screw extruder to melt and blend, extrude and granulate, the screw speed is 280 rpm, and the barrel temperature (temperature) is:

[0050] Hopper Zone 1, Zone 2, Zone 3, Zone 4, Zone 5, Zone 6, Zone 7, Zone 8, Zone 9

[0051] Room temperature 165 170 175 180 185 185 190 190 190 185.

Embodiment 2

[0053] Take the following materials by weight:

[0054] 100 parts of polyoxymethylene, 20 parts of treated green silicon carbide (the treatment method is the same as in Example 1), 0.2 parts of white oil, 0.4 parts of calcium stearate, antioxidant 2246: 0.4 parts, antioxidant 168: 0.4 parts, 0.8 parts of melamine-formaldehyde condensate, 0.3 parts of magnesium oxide, and 0.2 parts of titanium dioxide; dry polyoxymethylene at 80°C for 3 hours, then add the above-mentioned other materials into a high-speed mixer and mix;

[0055] A vented co-rotating twin-screw extruder is used for melt blending, extrusion and granulation, the screw speed is 210 rpm, and the barrel temperature (°C) is:

[0056] Hopper Zone 1, Zone 2, Zone 3, Zone 4, Zone 5, Zone 6, Zone 7, Zone 8, Zone 9

[0057] Room temperature 160 165 170 170 175 175 180 180 180 175.

Embodiment 3

[0059] Take the following materials by weight:

[0060] 100 parts of polyoxymethylene, 5 parts of treated green silicon carbide (the treatment method is the same as in Example 1), 0.1 part of white oil, 0.2 part of calcium stearate, 245 antioxidants: 0.6 parts, 168 antioxidants: 0.3 parts, 0.5 part of melamine, 0.4 part of magnesium oxide, and 0.1 part of diatomaceous earth. Dry the polyoxymethylene at 80°C for 3 hours, then add the above-mentioned other materials into the high-speed mixer and mix;

[0061] A vented co-rotating twin-screw extruder is used for melt blending, extruding and granulating, the screw speed is 250 rpm, and the barrel temperature (°C) is:

[0062] Hopper Zone 1, Zone 2, Zone 3, Zone 4, Zone 5, Zone 6, Zone 7, Zone 8, Zone 9

[0063] Room temperature 160 170 170 175 180 180 185 185 185 180.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com