Opaque white coating with non-conductive mirror

A mirror, transparent technology, applied in coatings, mirrors, electrical components, etc., can solve the problems of sensor reading errors and affect sensor performance, and achieve the effect of improving performance, reducing thickness, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

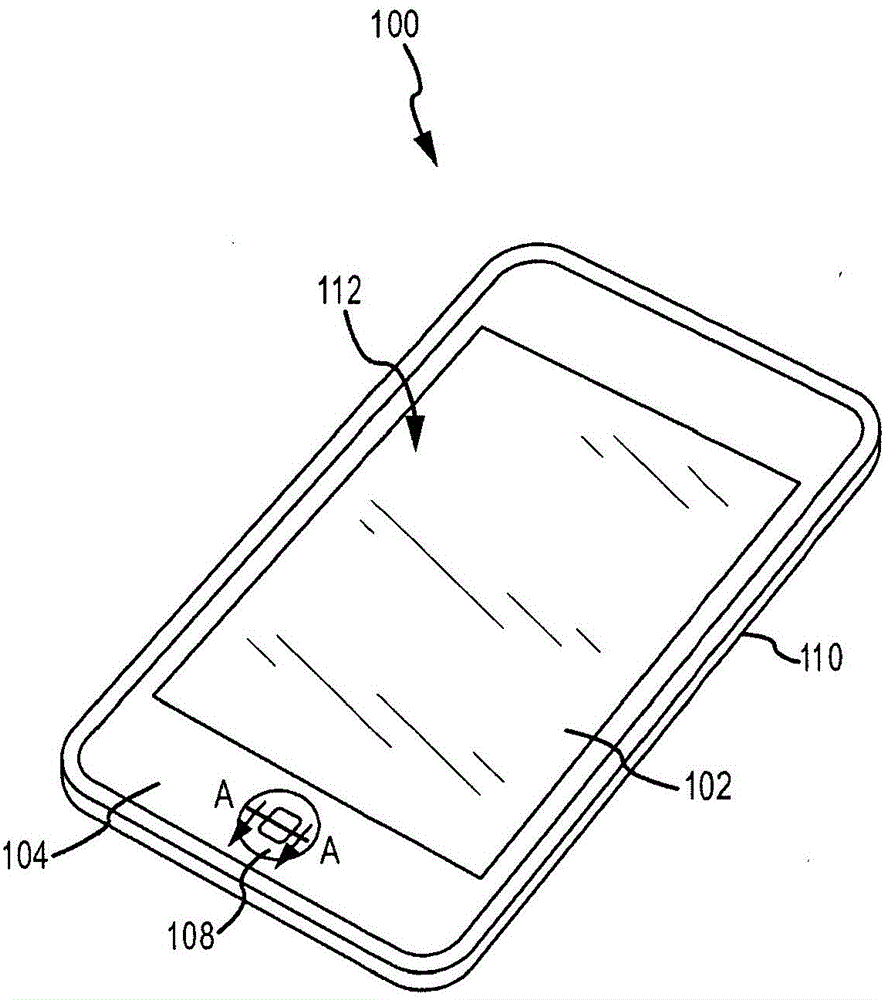

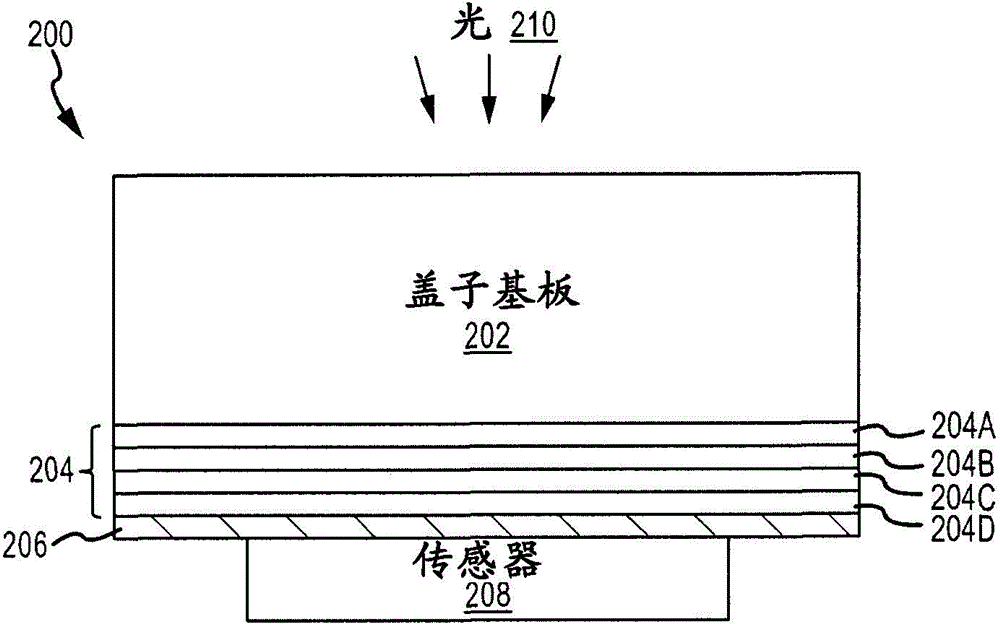

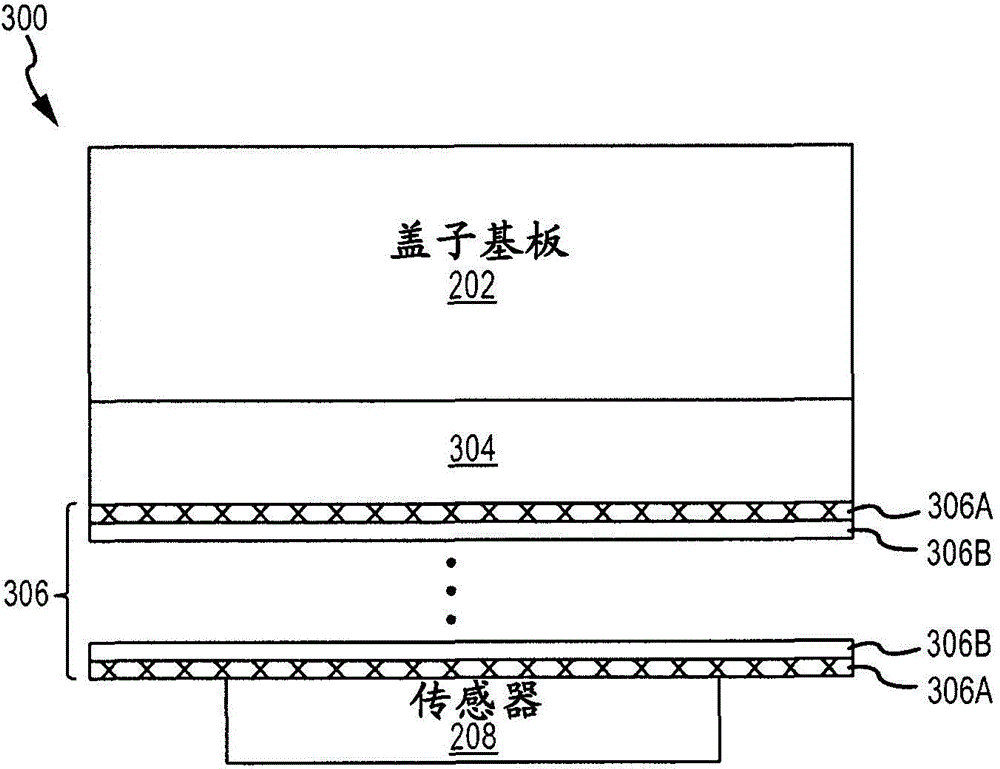

[0023] The present disclosure can be understood by referring to the following detailed description when taken in conjunction with the accompanying drawings as described below. It should be noted that, for clarity of illustration, some of the elements in the various figures may not be drawn to scale, may be represented schematically or conceptually, or otherwise may not correspond exactly to certain physical configurations of the embodiments.

[0024] The disclosure provides a mirror structure between the white ink or coating and a highly sensitive sensor, such as a capacitive sensor. A layer of white ink may underlie a glass or sapphire upper surface, such as a cover glass, and may hide the capacitive sensor from view. The white ink layer may include white pigments such as titanium oxide (TiO 2 ). Mirror structures can include silicon oxide (SiO 2 ) layer with niobium pentoxide (Nb 2 o 5 ) first stack of interleaved layers. with TiO 2 Compared to SiO 2 and Nb 2 o 5 H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com