Coke dry quenching oven coke discharge test method

A technology of a CDQ oven and a verification method, which is applied in the field of the verification of the coke discharge amount of the CDQ oven, can solve the problems of high frequency, many times of verification of the coke discharge amount, and many participants, etc. It is convenient to control, verify and adjust, and maintain the effect of the amount of coke removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

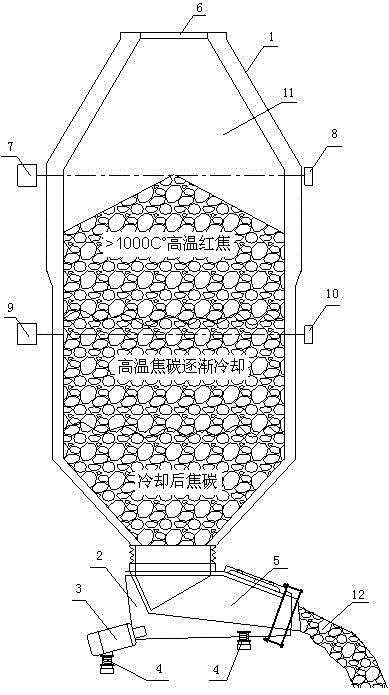

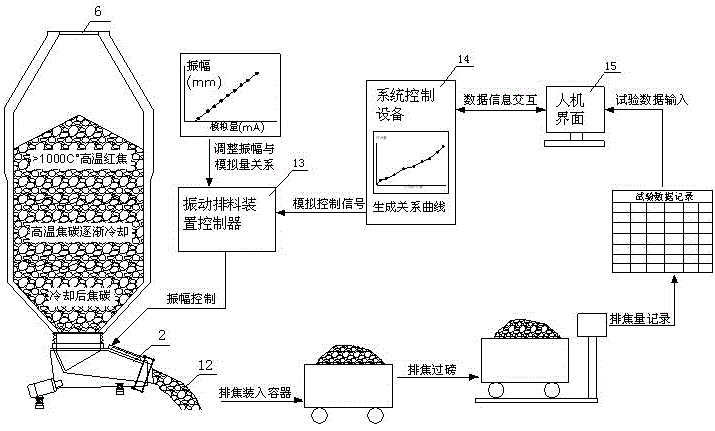

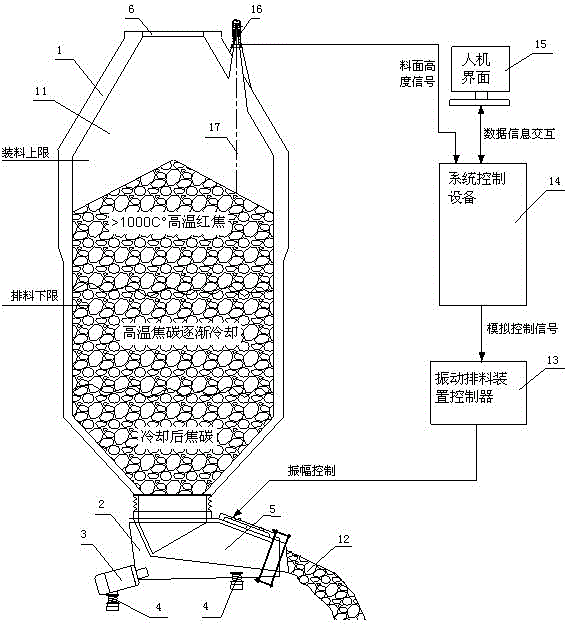

[0070] 1) Relevant conditions and parameters: There is a dry quenching furnace, the diameter of the red coke pre-storage chamber is 6m; the height between the upper limit of charging and the lower limit of discharge is 7m; the specific gravity of coke is 0.5t / m 3 ;The rated output of the vibrating discharge device is 30-100t / h; the rated amplitude of the vibrating discharge device is 0.4-1.2mm; a microwave material level detection device is installed on the upper part of the furnace body to continuously detect the material level in the CDQ furnace Changes in real time. The process stipulates that when the red coke is loaded to the upper limit of the charging, the charging will be stopped, and the volume of the red coke pre-storage room is r 2 *π*h=9*π*7=197.92m 3 ; The red coke pre-storage room can hold coke as 0.5*197.92=98.96t; the coke amount per meter height of the red coke pre-storage room is 98.96 / 7=14.137t / m.

[0071] 2) In the system control equipment, compile the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com