Rice bran soluble dietary fiber, production technology and application thereof

A dietary fiber and production process technology, applied in the field of biochemical preparation, can solve the problems of high price and insufficient raw materials, etc., and achieve the effect of increasing yield, improving yield, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

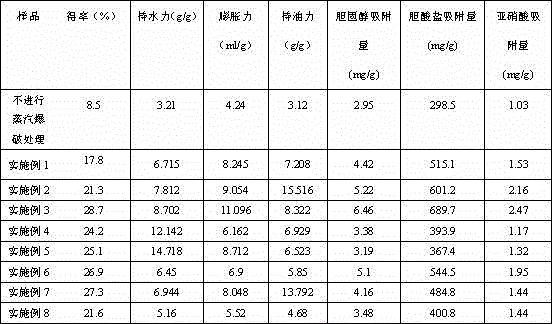

Embodiment 1

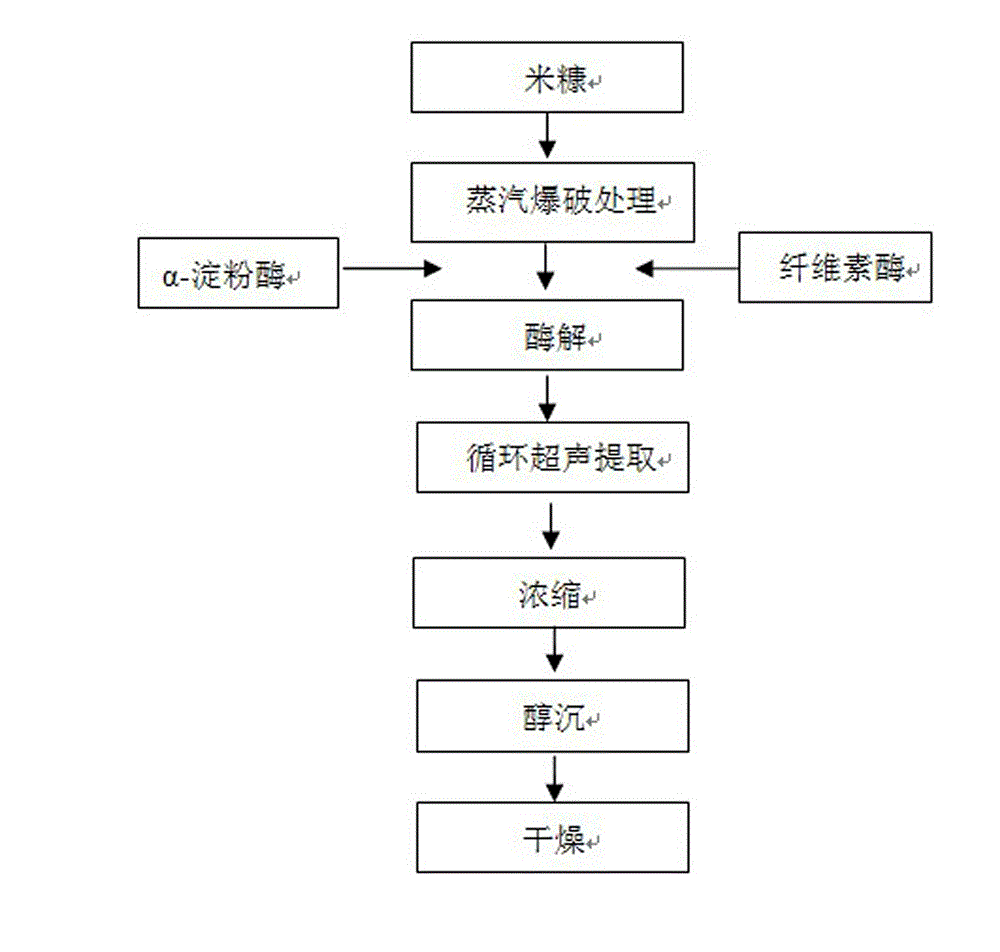

[0034] A production process of rice bran soluble dietary fiber, comprising the following steps:

[0035] (1) Pretreatment of rice bran: the rice bran is crushed to 20 mesh, soaked in 0.35% hydrochloric acid solution for 10 h according to the ratio of solid to liquid 1:28, washed with water until the pH is neutral, and steamed at 121 °C and 0.18 MPa. Blasting for 25 minutes;

[0036] (2) Enzymolysis: Add α-amylase to rice bran after steam explosion under stirring, enzymolysis temperature 40°C, dosage 1.5%, enzymolysis time 40min; add cellulase after enzymolysis, enzyme dosage 0.5% Enzymolysis was carried out in a water bath at 35°C for 50 min with constant stirring;

[0037] (3) Extraction and separation: add 25 times of water to the enzymatically hydrolyzed rice bran, and conduct cyclic ultrasonic extraction. The extraction conditions are: ultrasonic power 1000W, ultrasonic duty ratio 1:2, ultrasonic time 100min; cycle speed 900rpm, ultrasonic extraction ends Afterwards, the...

Embodiment 2

[0042] A production process of rice bran soluble dietary fiber, comprising the following steps:

[0043] (1) Pretreatment of rice bran: crush rice bran to 60 mesh, add 0.5% hydrochloric acid solution to soak for 15 hours according to 1:30 solid-liquid ratio, wash with water until the pH is neutral, and carry out steam explosion under the conditions of 125°C and 0.20 MPa 30min;

[0044] (2) Enzymolysis: Add α-amylase to rice bran after steam explosion under stirring, enzymolysis temperature 45°C, enzyme dosage 1.5%, enzymolysis time 40min; after enzymolysis, add cellulase, enzyme dosage 1.5 %Enzymolysis in a water bath at 35°C for 50 min with constant stirring;

[0045](3) Extraction and separation: Add 30 times of water to the enzymatically hydrolyzed rice bran, and perform circular ultrasonic extraction. The extraction conditions are: ultrasonic power 1500W, ultrasonic duty ratio 1:3, ultrasonic time 110min; cycle speed 1000rpm, ultrasonic extraction ends Afterwards, the so...

Embodiment 3

[0050] A production process of rice bran soluble dietary fiber, comprising the following steps:

[0051] (1) Pretreatment of rice bran: the rice bran is crushed to 20 mesh, soaked in 0.1% hydrochloric acid solution for 15 hours according to the ratio of solid to liquid at 30, washed with water until the pH is neutral, and subjected to steam explosion for 20 minutes at 120 °C and 0.20 MPa ;

[0052] (2) Enzymolysis: Add α-amylase to rice bran after steam explosion under stirring, enzymolysis temperature 45°C, enzyme dosage 1%, enzymolysis time 40min; after enzymolysis, add cellulase, enzyme dosage 1.5 %Enzymolysis in a water bath at 35°C for 35 min with constant stirring;

[0053] (3) Extraction and separation: add 30 times water to the enzymatically hydrolyzed rice bran, and carry out cyclic ultrasonic extraction. The extraction conditions are: ultrasonic power 500 W, ultrasonic duty ratio 1:3, ultrasonic time 50 min; cycle speed 1000 rpm, ultrasonic After the extraction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com