Amorphous nano copper sulphide composite material, preparation method and application thereof

A technology of composite materials and copper sulfide, applied in the field of environmental governance, can solve the problems of unfavorable separation, recovery and regeneration, large water head loss, blockage of adsorption column, etc., and achieve the effect of easy recovery and regeneration, not easy to lose, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

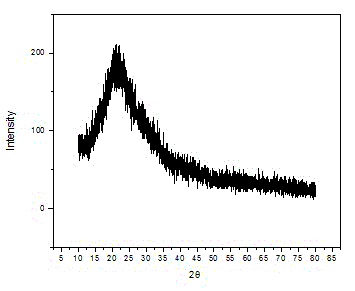

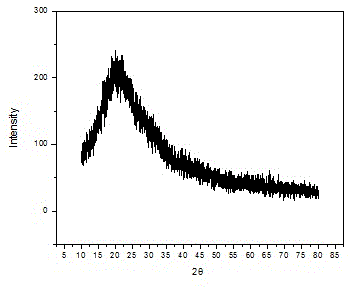

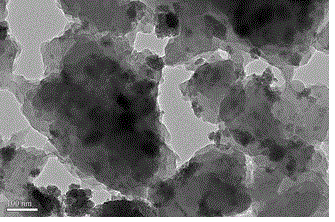

[0023] Weigh 4g of macroporous strongly acidic cation exchange resin D001 into a 250mL Erlenmeyer flask, add 100mL of 0.02mol / L CuCl2·2H2O aqueous solution, shake at a constant temperature of 298K for 5h, and filter out the resin adsorbed with copper ions. Put the resin adsorbed with copper ions in a 100mL Erlenmeyer flask, add 50mL, 0.05mol / L Na2S 9H2O aqueous solution, shake at a constant temperature at 283K for 12h, filter out with a nylon filter cloth, wash with distilled water and ethanol three times alternately, 313K dry under conditions to obtain the nano-copper sulfide composite material 1. The solid loading amount of CuS in the composite material is 51.53mg / g. From figure 1 and figure 2 It can be seen from the comparison that there is no characteristic peak of copper sulfide in the nano-copper sulfide composite material 1, and no new strong characteristic peak appears, indicating that the supported copper sulfide is amorphous copper sulfide. From image 3 It can ...

Embodiment 2

[0028] Load 1 g of nano-copper sulfide composite material 2 into a jacketed glass adsorption column (Φ12×160 mm). The concentration of tetracycline in the influent water is 100mg / L, the pH value is adjusted to about 5, and the flow rate is 24mL / h through the glass adsorption column under the condition of 25±5°C, and the treatment capacity is 2000mL / batch. After being adsorbed by the nano-copper sulfide composite material 2, the average concentration of tetracycline in the effluent is <0.05mg / L.

[0029] When the adsorption reaches the leakage point (the immediate concentration of tetracycline in the adsorbed water is 2% of the influent concentration), the adsorption is stopped. At a temperature of 30±5°C, an aqueous solution containing 0.01mol / L sodium hydroxide and 10% ethanol is passed through the adsorption column to desorb and regenerate the composite material 2.

Embodiment 3

[0031] Weigh 4g of macroporous strongly acidic cation exchange resin D001 into a 250mL Erlenmeyer flask, add 100mL of CuCl2 2H2O aqueous solution with a concentration of 0.04mol / L, shake at a constant temperature of 290K for 5h, and filter out the resin with copper ions. Put the resin with copper ions in a 100mL Erlenmeyer flask, add 50mL, 0.1mol / L Na2S·9H2O aqueous solution, shake at a constant temperature at 280K for 12h, filter it out with a nylon filter cloth, wash it with distilled water and ethanol three times alternately, Dry at 313K to obtain nano-copper sulfide composite material 3. The CuS immobilization capacity of the composite material is 104.93 mg / g. Comparing the XRD pattern of nano-copper sulfide composite material 3 and the XRD pattern of D001 resin, it can be seen that there is no characteristic peak of copper sulfide in the synthesized nano-copper sulfide composite material 3, and no new strong characteristic peak appears, indicating that the The supported c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com