A beneficiation process for treating slimy fine-grained niobium ore

A process and fine-grained technology, applied in the field of mineral processing, can solve the problems of particle size limit, poor sorting effect, and great influence on the sorting effect, and achieve the effect of improving recovery rate, good economic benefits, and simplifying the desliming process of gravity separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

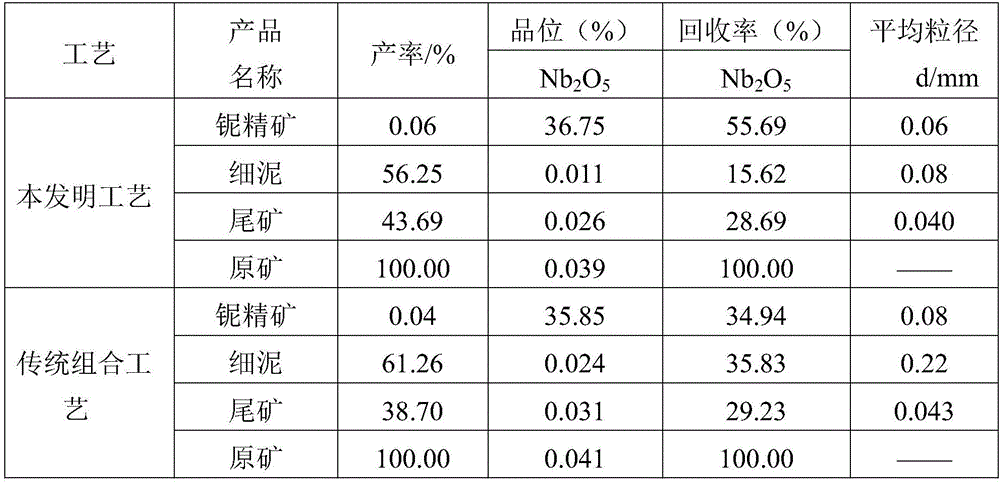

[0028] A fine-grained niobium ore in Nanping, Fujian Province. The niobium-containing minerals in the ore are mainly brown yttrium niobium ore (niobium mineral rich in heavy rare earths), complex rare gold ore, followed by trace niobite and niobium iron rutile. The gangue minerals are mainly are mica, quartz and calcite. The ore contains 0.04% niobium and <0.005% tantalum.

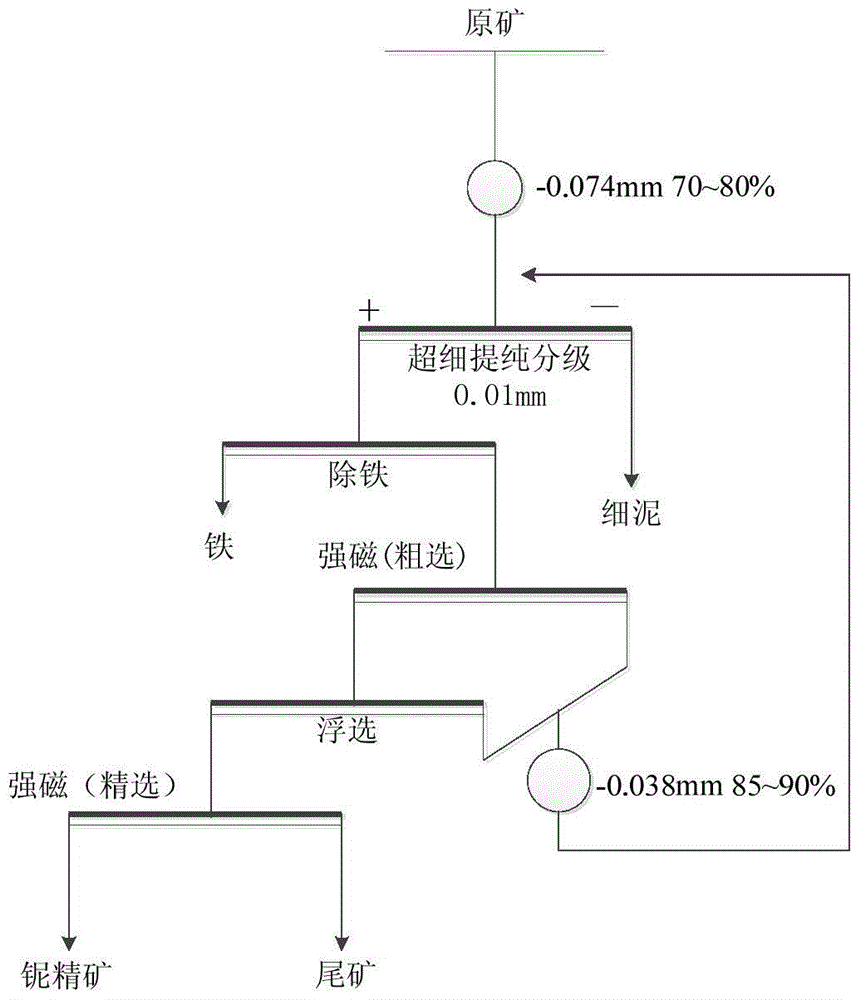

[0029] (1) Utilize the mineral processing of the inventive method

[0030] Grind the raw ore to -0.074mm 70%, and use an ultra-fine purification classifier (produced by Beijing Paleozoic Powder Technology Co., Ltd.) for gravity separation and desliming. The gravity concentration is 10% (weight ratio) and the working pressure is 0.70MPa. Gravity separation sand settling is carried out under the condition of magnetic field strength of 1200Oe and ore concentration of 10% (weight ratio) to remove iron by weak magnetic field. After sand settling and iron removal, strong magnetic roughing is carried out. The o...

Embodiment 2

[0036] A fine-grained niobium ore in Kangding, Sichuan. The niobium-containing minerals in the ore are mainly niobium-ironite, followed by niobium-iron-rutile, and the gangue minerals are mainly quartz, kaolin and calcite. The ore contains 0.060% niobium.

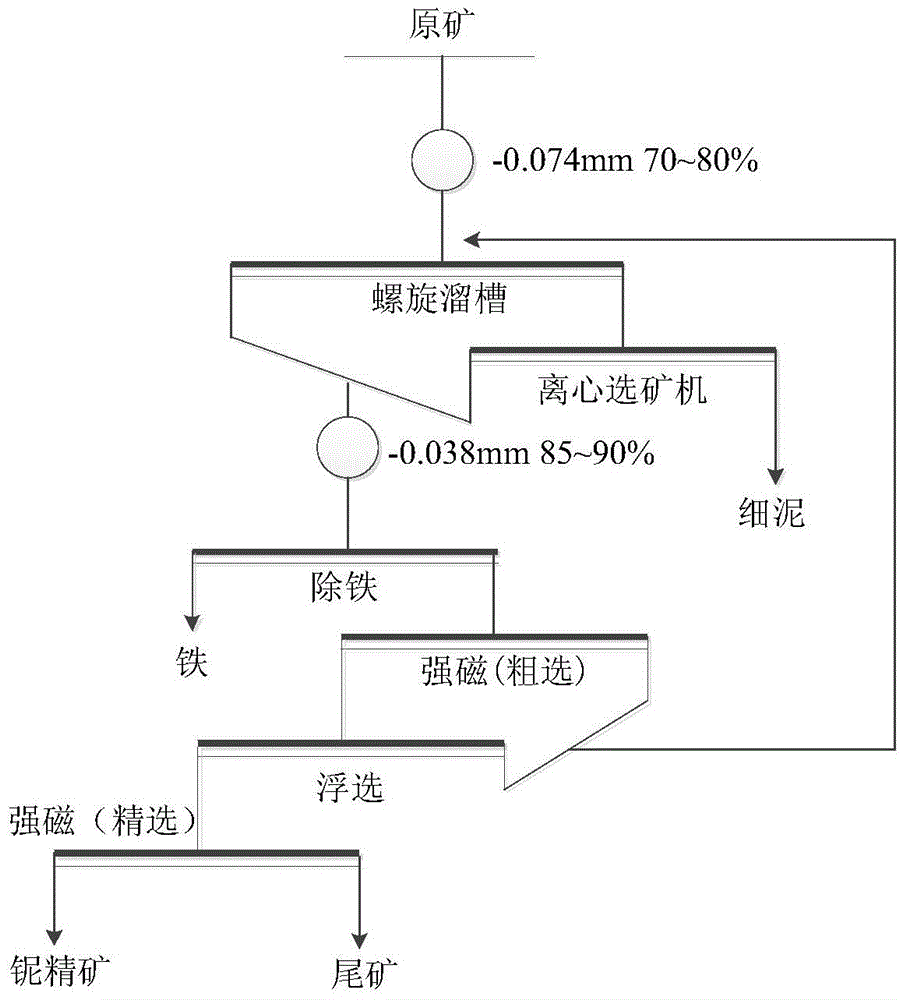

[0037] (1) Utilize the mineral processing of the inventive method

[0038] Grind the raw ore to -0.074mm 78%, adopt ultra-fine purification classifier (produced by Beijing Paleozoic Powder Technology Co., Ltd.) for gravity separation and desliming, gravity concentration is 10% (weight ratio), working pressure is 0.75MPa; gravity separation Sand settling carries out weak magnetic iron removal under the conditions of magnetic field intensity of 1200Oe and ore concentration of 10% (weight ratio); after sand settling and iron removal, strong magnetic roughing is carried out, and strong magnetic roughing ore concentration is 15%, and the magnetic field strength is 20000Oe; strong magnetic (rough separation) coarse concentrate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com