A novel tin dioxide semiconductor and its preparation method and application

A tin dioxide and semiconductor technology, which is applied in the field of novel tin dioxide semiconductor photocatalyst and its preparation, can solve the problems of limited application, insufficient theory, and less research on visible photochemistry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

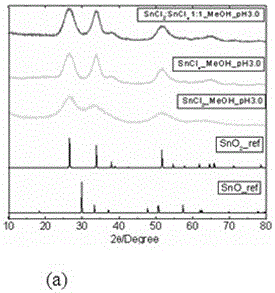

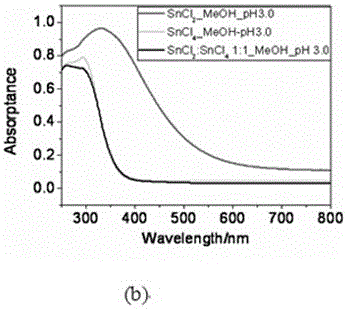

[0017] Weigh SnCl 2 .2H 2 O 4.514g was dissolved in 1 liter of absolute ethanol to prepare SnCl with a concentration of 20mmol / L 2 .2H 2 O ethanol solution, hydrothermal reaction at 150°C for at least 24h in a hydrothermal reaction kettle, stand and filter, and dry the filtered solid at 50-80°C to obtain the product. The average grain size of the product is 2.5nm, and the absorption edge reaches 570nm, corresponding to a band gap of 2.17eV. The XRD spectrum is shown in Figure 1(a), and the UV-Vis absorption spectrum is shown in Figure 1(b).

Embodiment 2

[0019] Weigh SnCl 2 .2H 2 O 6.294g was dissolved in 1 liter of anhydrous methanol to prepare SnCl with a concentration of 20mmol / L 2 .2H 2 O methanol solution, hydrothermal reaction at 150°C for at least 24h in a hydrothermal reaction kettle, stand and filter, and dry the filtrated solid at 50-80°C to obtain the product. The average grain size of the product is 2.5nm, and the absorption edge reaches 570nm, corresponding to a band gap of 2.17eV. The XRD spectrum is shown in Figure 1(a), and the UV-Vis absorption spectrum is shown in Figure 1(b).

Embodiment 3

[0021] Weigh SnCl 2 .2H 2 O 4.514g was dissolved in 1 liter of anhydrous methanol to prepare SnCl with a concentration of 20mmol / L 2 .2H 2 O methanol solution, hydrothermal reaction at 150°C for at least 24h in a hydrothermal reaction kettle, stand and filter, and dry the filtrated solid at 50-80°C to obtain the product. The average grain size of the product is 2.5nm, and the absorption edge reaches 570nm, corresponding to a band gap of 2.17eV. The XRD spectrum is shown in Figure 1(a), and the UV-Vis absorption spectrum is shown in Figure 1(b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com