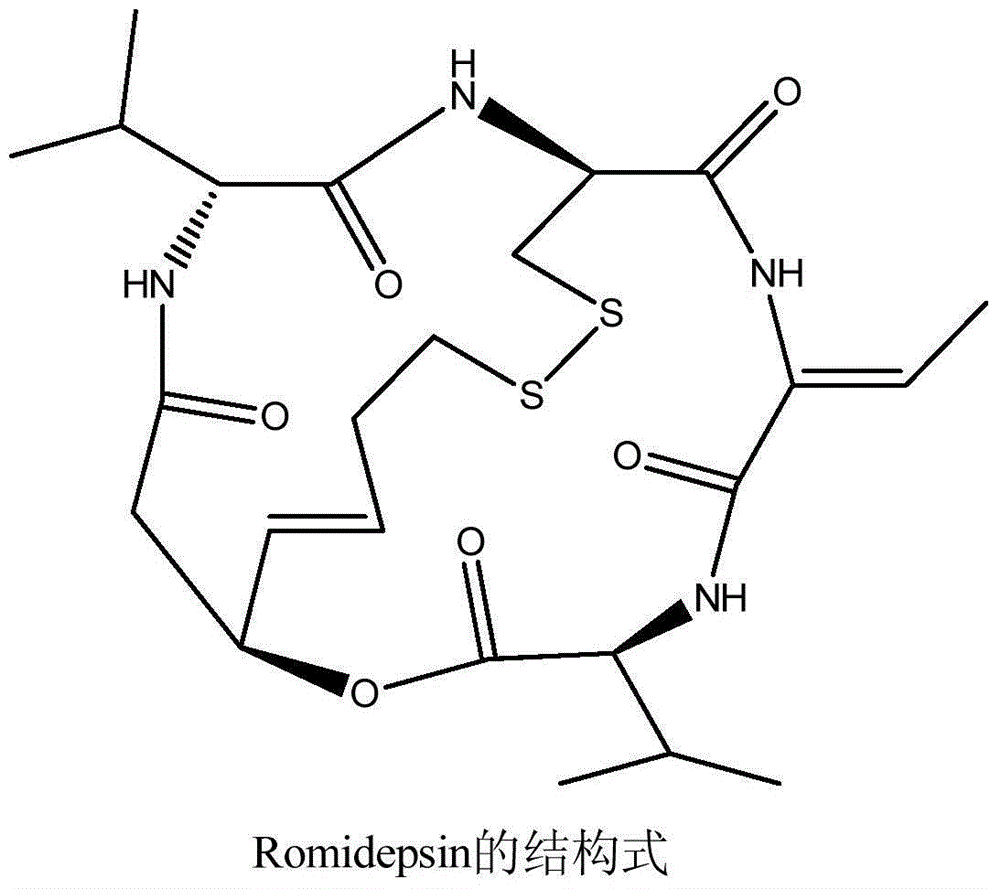

Romidepsin separation and purification method

A technology for separation and purification of romidepsin, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of complex operation, low yield, and many reagents and instruments, and achieve simple purification process, The effect of high extraction purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] a. Add 3 L of Chromobacterium violaceum WB968 fermentation broth containing romidepsin to 150 g of SP825 macroporous adsorption resin, and stir for 20 min until the adsorption is complete as detected by HPLC.

[0039] b. Separate the macroporous resin adsorbed with romidepsin from the fermentation broth, put the SP825 adsorbed with romidepsin on the column, and wash with tap water until clarified. Romidepsin was eluted with 1.5L acetone to obtain eluent 1. The eluate 1 was concentrated under reduced pressure to obtain a brown-black concentrated solution 1 .

[0040] c. Load concentrated solution 1 to SP825 macroporous adsorption resin (the mass volume ratio of SP825 and concentrated solution 1 is 0.07g / mL), and use acetone and water mixed solvent 2 (the volume ratio of acetone and water is 3:7) For washing, the flow rate sv is controlled not to exceed 7, and then the mixed solvent 3 of acetone and water (the volume ratio of acetone to water is 4.5:5.5) is used for elut...

Embodiment 2

[0045] Other conditions remained unchanged relative to Example 1, and the stirring time was changed to 35 minutes. The finally obtained romidepsin was detected by HPLC with a purity of 97% and a yield of 85%.

Embodiment 3

[0047] Other conditions remained unchanged relative to Example 1, and the stirring time was changed to 60 min. The finally obtained romidepsin was detected by HPLC with a purity of 93% and a yield of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com