Coating system for aerial aircraft

A technology for aircraft and coatings, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor surface gloss retention rate and color durability, easy chalking, harsh coating quality, etc., to ensure delivery Joint density and flexibility, improved weather resistance, reasonable matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 prepares the component A1 of anticorrosion coloring primer

[0033] The components of the anti-corrosion coloring primer of the aviation vehicle coating system of the present invention A1 and their mass percentages are as follows: hydrogenated epoxy resin 15%~30%, modified resin 2%~10%, coloring pigment 10%-20%, environment-friendly anti-corrosion pigment 10%-20%, filler 5-15%, auxiliary agent 0.5%-1%, and the balance is composed of solvent.

[0034] (1) Preparation of raw materials

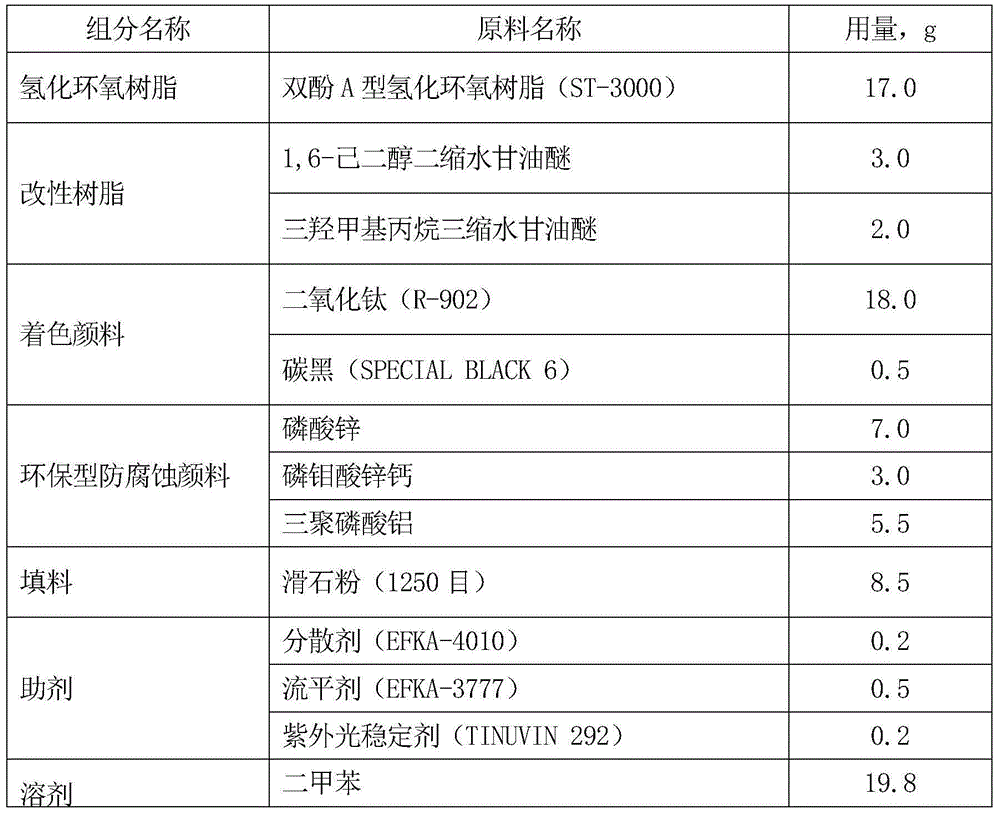

[0035] Prepare the raw materials according to the ratio in Table 1.

[0036] The components and their mass percentages of Example 1 component A1 are as follows: 17.0% hydrogenated epoxy resin, 5.0% modified resin, 18.5% colored pigment, 15.5% environmentally friendly anti-corrosion pigment, 8.5% filler, auxiliary agent 0.9%, the solvent is 34.6% composition. The specific formula is shown in Table 1.

[0037] Table 1

[0038]

[0039]

[0040]Note: ST-3000 is hydroge...

Embodiment 2

[0043] Embodiment 2 prepares the component B1 of anticorrosion coloring primer

[0044] The components of the component B1 of the anti-corrosion coloring primer of the aircraft coating system of the present invention and their mass percentages are as follows: 3% to 15% of liquid epoxy resin, 5% of polyamines with primary amine groups ~25%, the balance is solvent.

[0045] (1) Preparation of raw materials

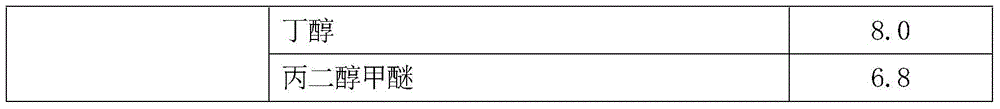

[0046] Prepare the raw materials according to the ratio in Table 2.

[0047] Example 2 The components and mass percentages of component B1 are as follows: 8.1% liquid epoxy resin, 22.6% polyamine with primary amine groups, and 69.3% solvent. The specific formula is shown in Table 2.

[0048] Table 2

[0049]

[0050]

[0051] (2) Preparation method

[0052] In the reaction kettle, add the polyamine and solvent with primary amino groups prepared in step (1) according to the formula amount in Table 2, and heat up to 60°C while stirring, then start to add the formula ...

Embodiment 3

[0053] Embodiment 3 prepares component A2

[0054] Each component of the component A2 of the weather-resistant transparent surface coating of the coating system for aircraft of the present invention and its mass percentage are as follows: polyol resin 50% ~ 80%, auxiliary agent 1% ~ 4%, the balance is solvent ;

[0055] (1) Preparation of raw materials

[0056] Prepare the raw materials according to the ratio in Table 3.

[0057] The components and their mass percentages of Example 3 component A2 are as follows: 71.4% polyol resin, 2.1% additives, and 26.5% solvent. The specific formula is shown in Table 3.

[0058] table 3

[0059]

[0060] Note: PE-6 is a polyester polyol resin (solid content: 70wt%, hydroxyl content: 6.0wt%) produced by CNOOC Changzhou Environmental Protection Coatings Co., Ltd.; TINUVIN 1130 is a benzotriazole UV absorber produced by BASF TINUVIN 292 is a hindered amine (HAL) UV light stabilizer produced by BASF; EFKA-3777 is a modified polyacrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Dry film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com