Method for brewing Fen-flavor Daqu liquor from avena nuda

A fragrant Daqu and naked oat technology, applied in the field of winemaking, can solve the problems of increasing living costs of residents, raising the CPI index, rising product prices, etc., achieving the effects of typical and unique wine aroma, lowering cholesterol, and facilitating absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

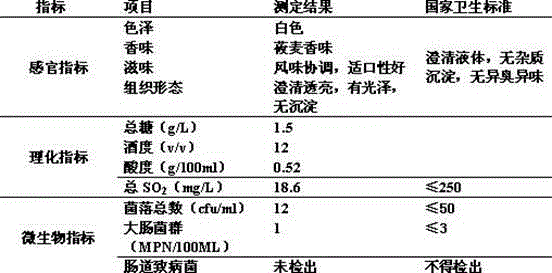

Examples

Embodiment 1

[0014] A method for brewing Fen-flavor Daqu liquor from naked oats, comprising the following steps:

[0015] (1) Selection of raw materials: full grains, no mildew, no moths, after removing impurities, enter the pulverizer for crushing; (2) Moisten grain: soak the crushed raw materials with hot water at 70°C, the amount of water added is 40% of the weight of the raw materials, so that the raw materials can absorb enough water, and naturally accumulate for about 15 hours. Before the grain is put on the screen, turn it over once, and sprinkle a layer of rice husk on the screen, and then add another layer of grain. After the steam rises evenly, add another layer of grain. It should be spread thinly and evenly. Spray water accounting for 3% of the total weight of the raw materials on the surface of the grain, and steam the material for 65 minutes; (4) ferment in the pond: after the steamed grain is out of the screen, add water accounting for 25% of the total weight of the raw mate...

Embodiment 2

[0017] A method for brewing Fen-flavor Daqu liquor from naked oats, comprising the following steps:

[0018] (1) Selection of raw materials: full grains, no mildew, no moths, after removing impurities, enter the pulverizer for crushing; (2) Moisten grain: soak the pulverized raw materials with hot water at 90°C, the amount of water added is 55% of the weight of the raw material, so that the raw material can absorb enough water and accumulate naturally for about 20 hours. Before the good grain is put on the screen, turn it over once, and sprinkle a layer of rice husk on the screen, and then add another layer of grain. After the steam rises evenly, add another layer of grain. It should be spread thinly and evenly. After the grain is sprayed with water accounting for 3% of the total weight of the raw material on the surface of the grain, steam the material for 80 minutes; (4) into the tank for fermentation: after the steamed grain is out of the screen, add water accounting for 40...

Embodiment 3

[0020] A method for brewing Fen-flavor Daqu liquor from naked oats, comprising the following steps:

[0021] (1) Selection of raw materials: full grains, no mildew, no insects, after removing impurities, enter the pulverizer for crushing; (2) Moisten grain: soak the crushed raw materials with 80°C hot water, the amount of water added is 55% of the weight of the raw material, so that the raw material can absorb enough water and accumulate naturally for about 18 hours. Before the good grain is put on the screen, turn it over once, and sprinkle a layer of rice husk on the screen, and then add another layer of grain. After the steam rises evenly, add another layer of grain. It should be spread thinly and evenly. After the grain is sprayed with water accounting for 3% of the total weight of the raw material on the surface of the grain, steam the material for 70 minutes; (4) into the tank for fermentation: after the steamed grain is out of the screen, add water accounting for 30% of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com