A kind of release film with silicon dioxide film layer and preparation method thereof

A technology of silicon dioxide film and release film, which is applied in coating, liquid chemical plating, metal material coating process, etc., and can solve problems such as difficult decomposition, high price, and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A kind of preparation method of the release film with silicon dioxide film layer, comprises the steps:

[0024] (1) Configure polysilazane solution: the concentration of polysilazane is 1%, and the solvent is organic solvent n-butyl ether;

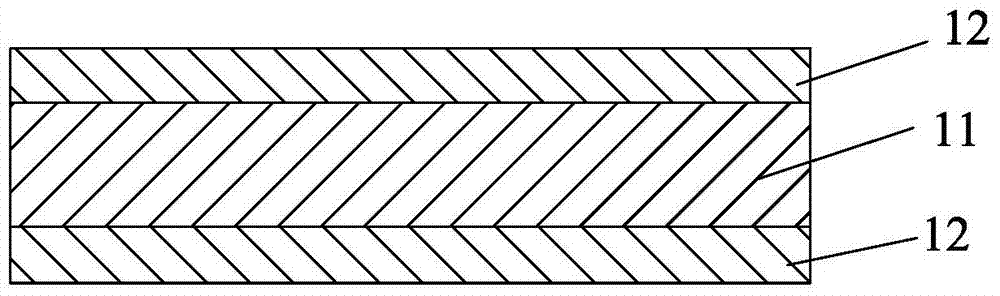

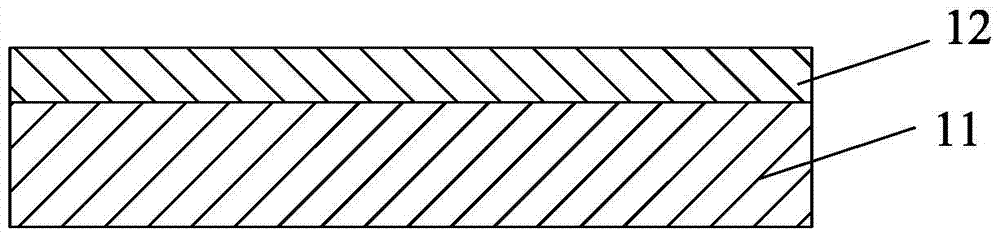

[0025] (2) Coating of base film: coating the above-mentioned polysilazane solution on one side of the 25 micron PET film, driving off the solvent, and drying; then coating the above-mentioned polysilazane solution on the other side of the PET film, driving off the solvent, and drying Dry; polysilazane solution coating dry thickness range: 20 nanometers;

[0026] (3) The product obtained in step (2) is wet heat treated in an oven with a relative humidity of 85% and a temperature of 85°C for 2 hours, and then baked at a temperature of 120-150°C for 2 hours to obtain a double-sided film with a silicon dioxide film layer. Release film.

[0027] Performance Testing:

[0028] The double-sided release film with silicon diox...

Embodiment 2

[0029] Embodiment 2 A kind of preparation method of the release film with silicon dioxide film layer, comprises the steps:

[0030] (1) Configure polysilazane solution: the concentration of polysilazane is 5%, and the solvent is organic solvent n-butyl ether;

[0031] (2) Coating of the base film: coating the above-mentioned polysilazane solution on one side of the 50-micron PET film, driving off the solvent, and drying; then coating the above-mentioned polysilazane solution on the other side of the PET film, driving off the solvent, and drying Dry; polysilazane solution coating dry thickness range: 100 nm;

[0032] (3) The product obtained in step (2) is wet heat treated in an oven with a relative humidity of 85% and a temperature of 85°C for 3 hours, and then baked at a temperature of 120-150°C for 2 hours to obtain a double-sided film with a silicon dioxide film layer. Release film.

[0033] Performance Testing:

[0034] Laminate the double-sided release film with a sili...

Embodiment 3

[0035] Embodiment 3 A kind of preparation method of the release film with silicon dioxide film layer, comprises the steps:

[0036] (1) Configure polysilazane solution: the polysilazane concentration is 10%, and the solvent is organic solvent n-butyl ether;

[0037] (2) Coating of base film: coating the above-mentioned polysilazane solution on one side of the 25 micron PET film, driving off the solvent, and drying; then coating the above-mentioned polysilazane solution on the other side of the PET film, driving off the solvent, and drying Dry; polysilazane solution coating dry thickness range: 200 nm;

[0038] (3) The product obtained in step (2) is wet heat treated in an oven with a relative humidity of 85% and a temperature of 85°C for 3 hours, and then baked at a temperature of 120-150°C for 2 hours to obtain a double-sided film with a silicon dioxide film layer. Release film.

[0039] Performance Testing:

[0040] Laminate the double-sided release film with a silicon di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com