Method for determining content of sodium chloride in hexamethylene 1, 6-disodium dithiosulfate dihydrate

A technology of disodium dithiosulfate and hexamethylene is applied in the field of determination of sodium chloride content and can solve problems such as large error in the method of sodium chloride content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

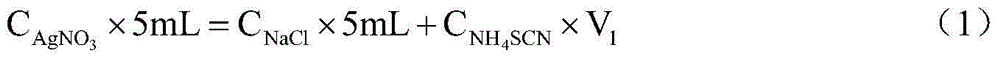

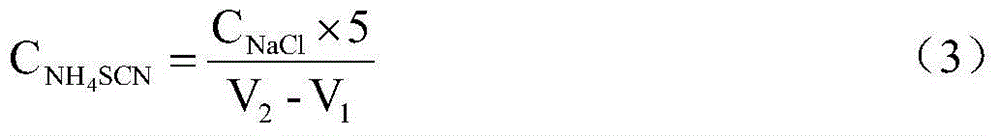

[0037] Specific embodiment one: this embodiment is the determination method of sodium chloride content in the hexamethylene 1,6-dithiosulfate disodium salt dihydrate, specifically completes according to the following steps:

[0038] 1. Solution preparation: ①. Prepare NaCl standard solution: Dissolve sodium chloride in distilled water, and use a volumetric flask to constant volume to obtain a NaCl standard solution with a concentration of 0.05mol / L; ②. Prepare AgNO 3 Solution: AgNO 3 Dissolve in distilled water, and use a brown volumetric flask to make constant volume to obtain AgNO with a concentration of 0.1mol / L 3 solution; ③, preparation of NH 4 SCN solution: NH 4 Dissolve SCN in distilled water and use a volumetric flask to constant volume to obtain NH 4 SCN solution; ④, preparation of ferric ammonium sulfate indicator: first add nitric acid to distilled water, then add NH 4 Fe(SO 4 ) 2 12H 2 O, stirred to NH 4 Fe(SO 4 ) 2 12H 2 O completely dissolves, namely o...

specific Embodiment approach 2

[0079] Specific embodiment two: the difference between this embodiment and specific embodiment one is: step one 4. prepare ferric ammonium sulfate indicator: first add nitric acid to distilled water, then add NH 4 Fe(SO 4 ) 2 12H 2 O, stirred to NH 4 Fe(SO 4 ) 2 12H 2 O completely dissolves, namely obtains the ferric ammonium sulfate indicator that mass fraction is 10%, the volume ratio of described distilled water and sulfuric acid is 10:1, and the mass fraction of described nitric acid is 65%. Others are the same as the first embodiment.

[0080] Adopt following test verification effect of the present invention

[0081] Test 1: The determination method of sodium chloride content in hexamethylene 1,6-dithiosulfate disodium salt dihydrate, specifically, it is completed according to the following steps:

[0082] 1. Solution preparation: ①. Prepare NaCl standard solution: Dissolve sodium chloride in distilled water, and use a volumetric flask to constant volume to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com